Preparation method and device for ambulance interior trimming panel

A technology for preparing devices and interior panels, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of high cost of raw materials and short service life, so as to improve the qualified rate of finished products, improve service life and heat resistance. and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

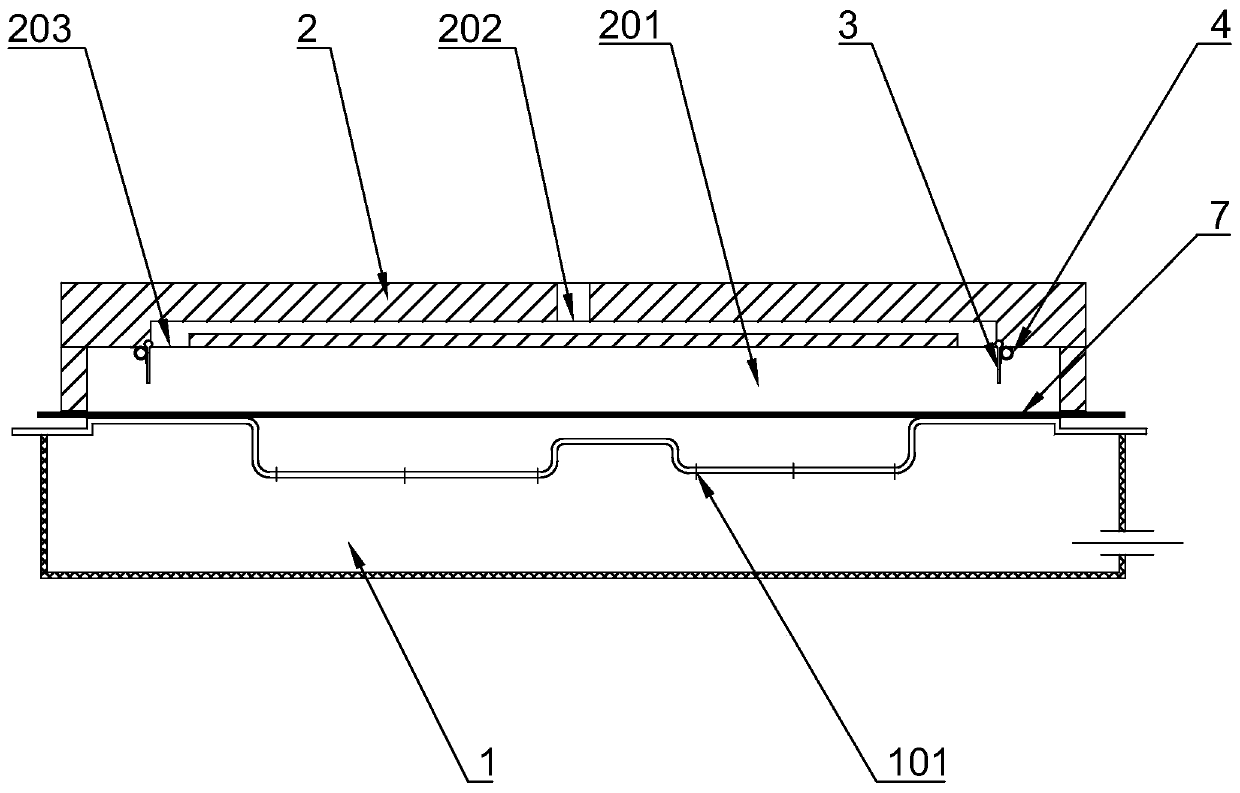

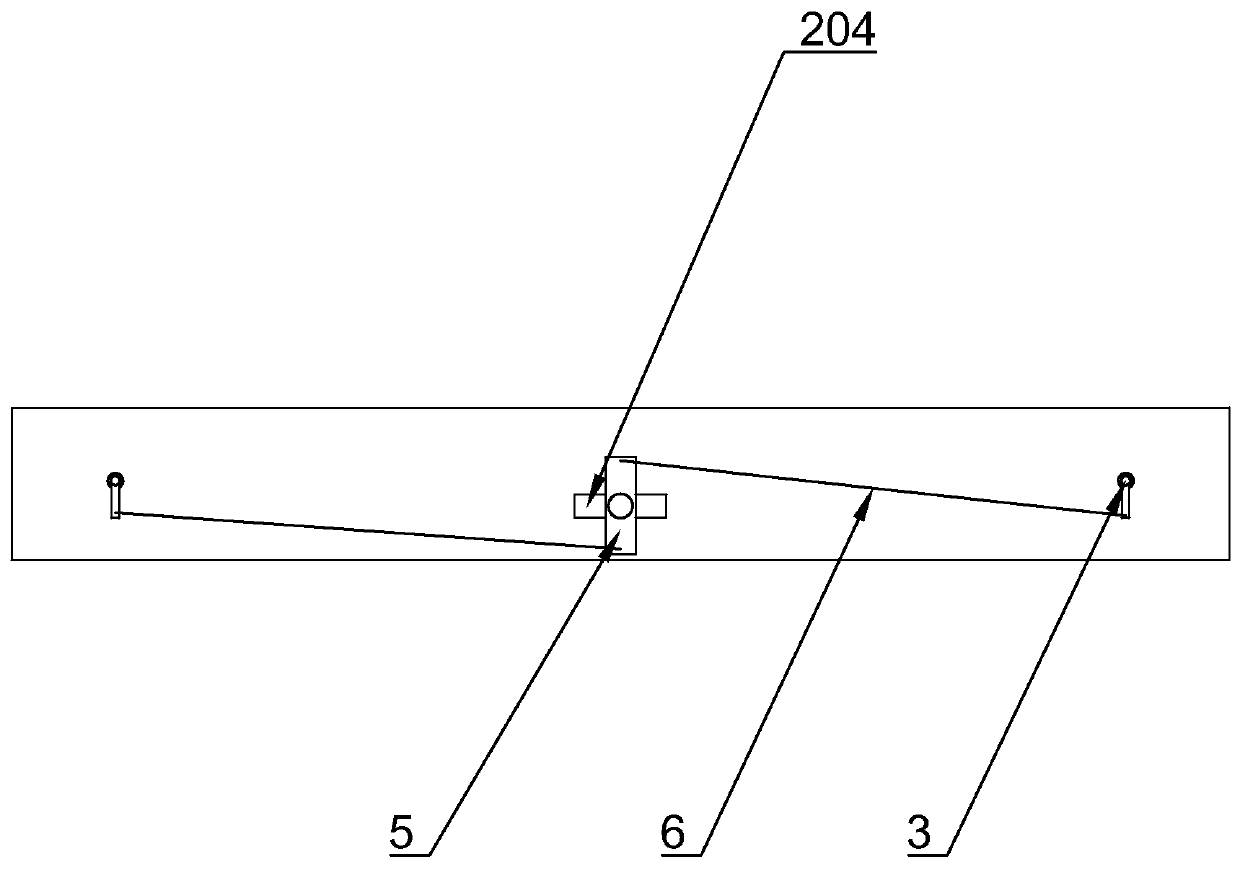

[0033] refer to figure 1 with figure 2 , the invention provides a kind of preparation method of ambulance trim panel, specifically comprises the following steps:

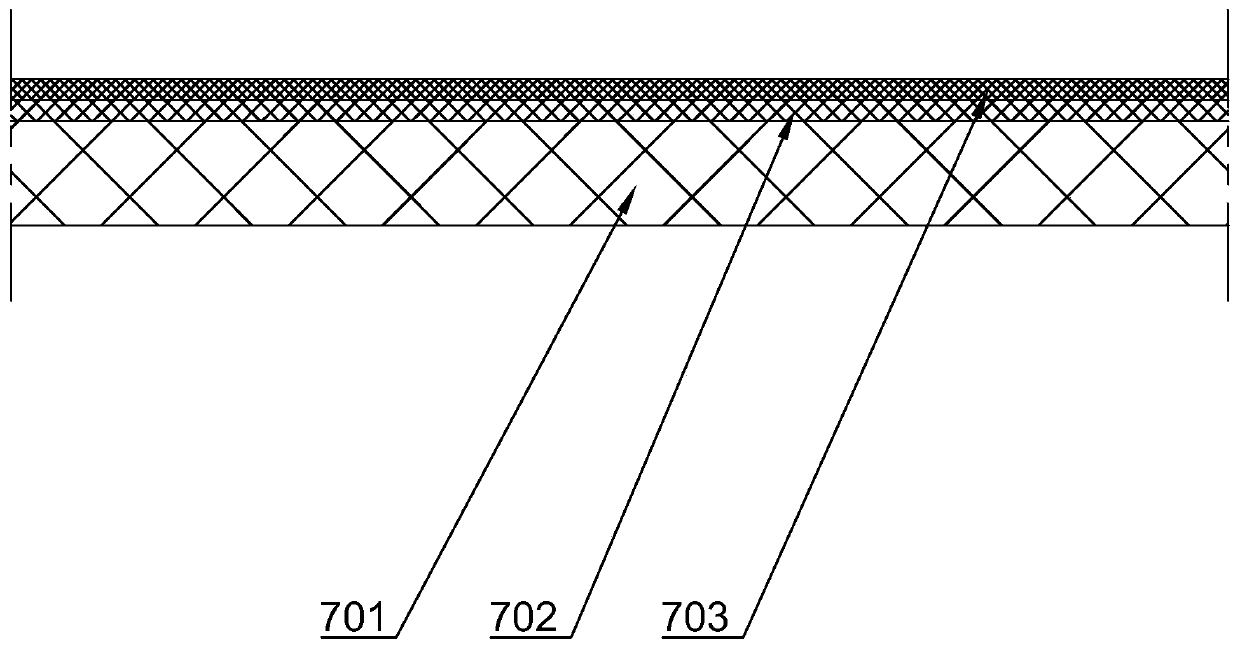

[0034] S1. A double-layer co-extrusion process is adopted to obtain a sheet blank 7, the upper surface of the sheet blank 7 is a PMMA material layer 702 with a thickness of 0.5 mm, and the lower surface is an ABS material layer 701 with a thickness of 5 mm;

[0035] S2. Cut the blank 7 to the corresponding size as required, then fix the blank 7 on the fixture, and move it to a high-temperature furnace for heating. The heating temperature is 150 degrees Celsius, and the heating time is 15 minutes to ensure that the blank 7 is completely softened;

[0036] S3. Move the plate to the top of the mold frame 1, and make the edge of the plate fit the edge of the mold frame 1, so that a sealed environment is formed between the plate and the mold frame 1;

[0037] S4, start the air pump to form a negative pressure between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com