Environment-friendly and energy-saving connecting piece for composite outer wallboard and production method thereof

An exterior wall panel and energy-saving technology, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of large impact on building durability, affecting the service life of buildings, aging resistance and poor durability, and achieve improvement Durability, improve heat preservation effect, ease labor rhythm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

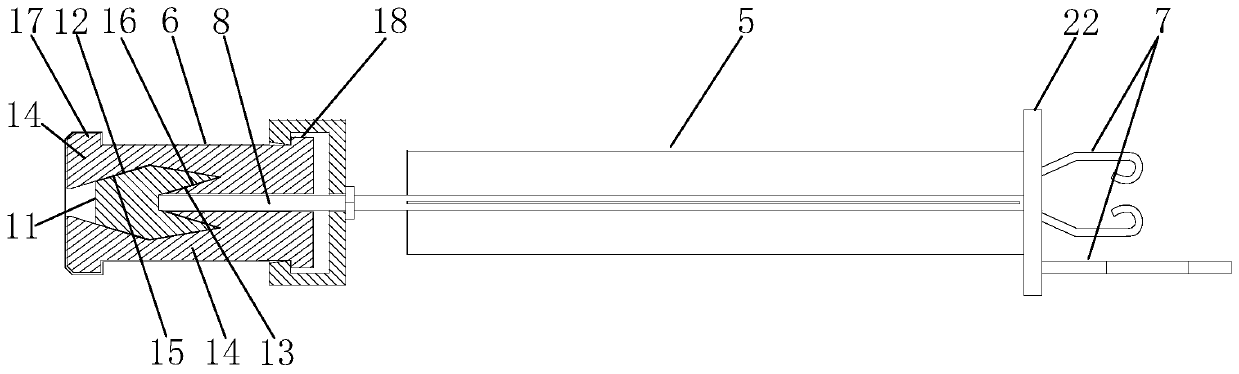

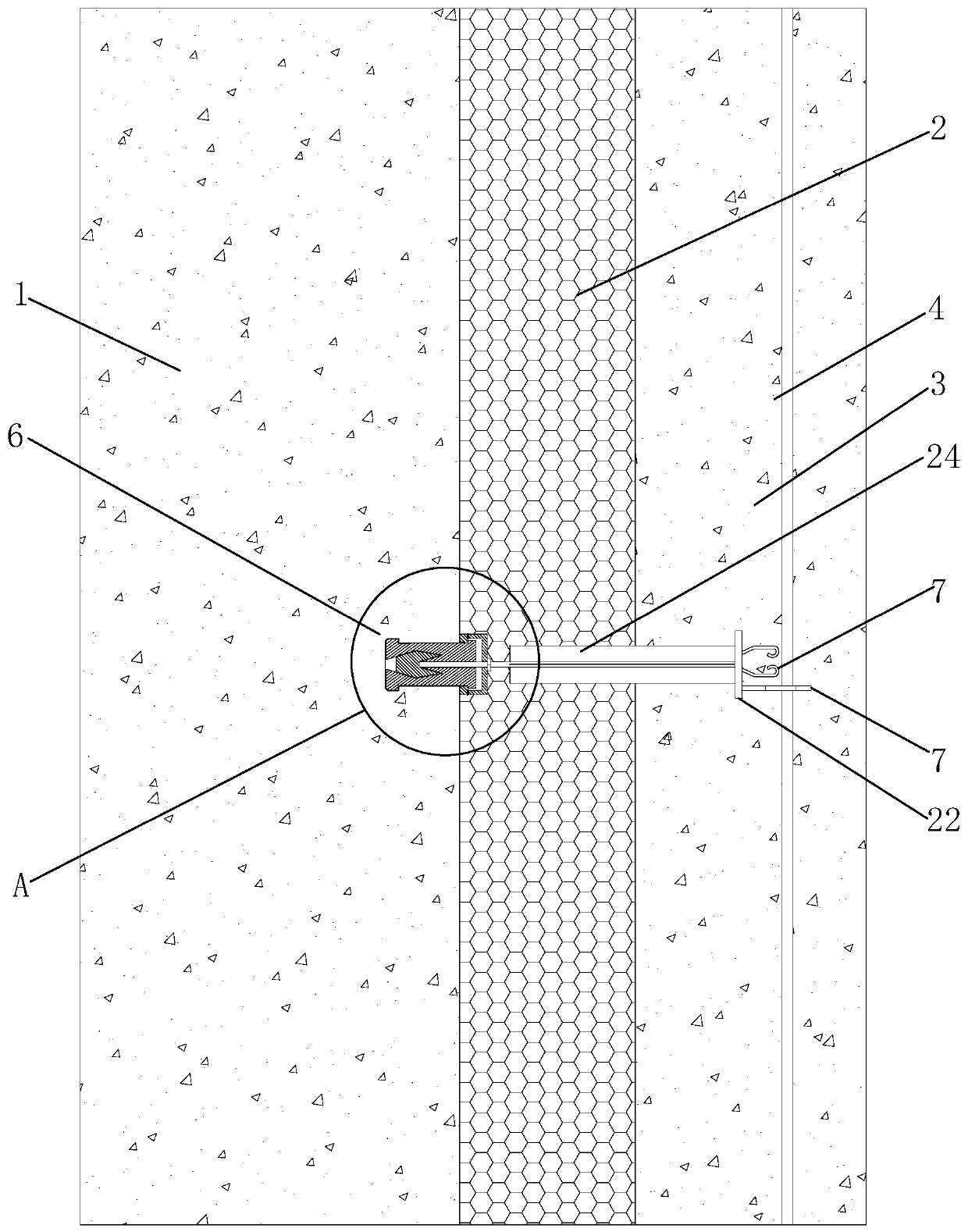

[0037] refer to figure 1 , is an environmentally friendly and energy-saving connector for a composite exterior wall panel disclosed by the present invention, which is composed of a connecting rod 5, an anchor 6, and a clamping member 7. The anchor 6 and the clamping member 7 are respectively connected to the connecting rod 5 ends.

[0038] Such as figure 2 As shown, the anchor piece 6 is used to anchor in the inner leaf wall 1 , and the clamping piece 7 is used to clamp the steel bar 4 in the outer leaf wall 3 .

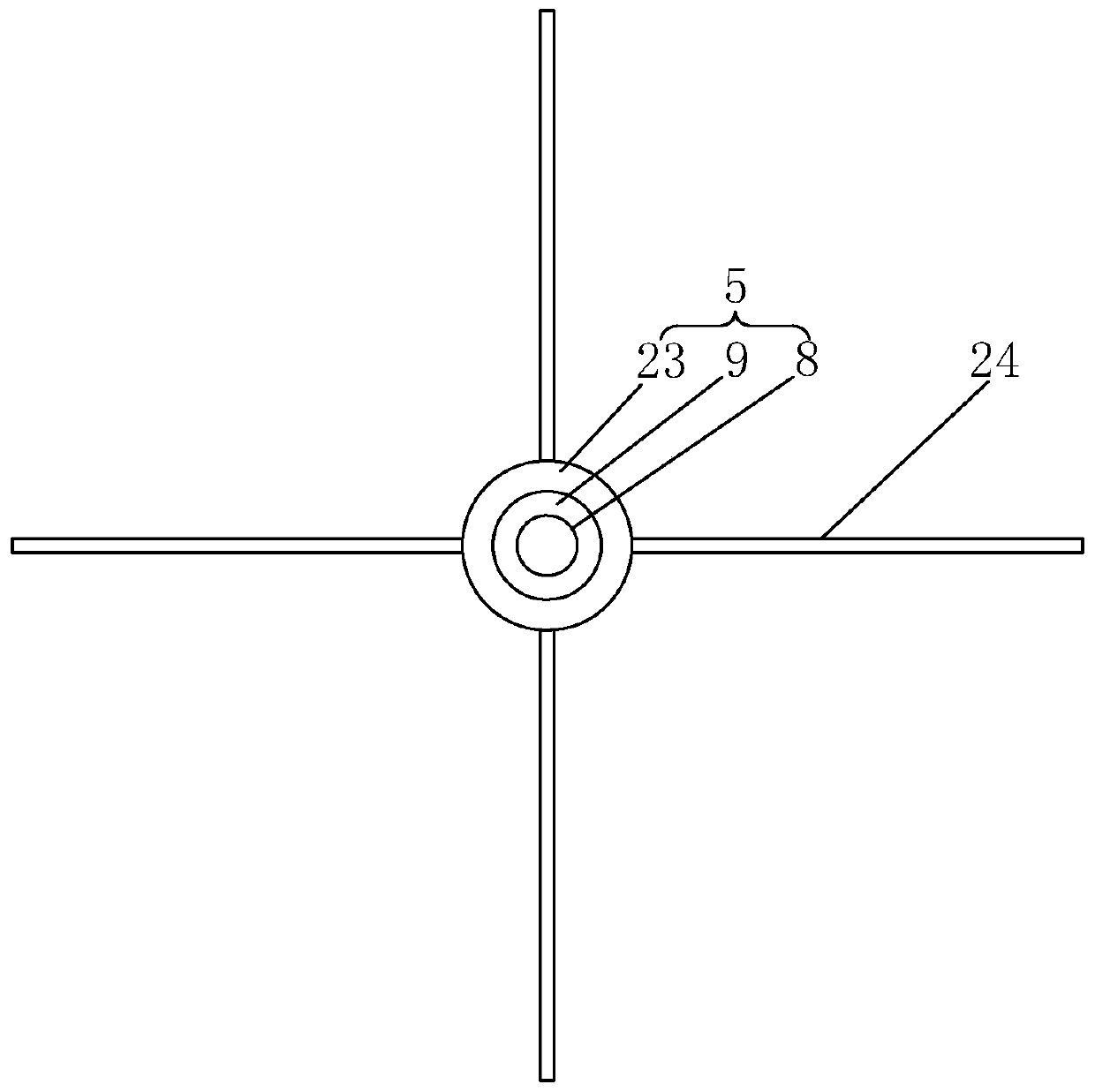

[0039] Such as image 3 As shown, the connecting rod 5 is sequentially composed of a metal core rod 8, an anti-aging rubber soft cover 9, and a hard anti-aging plastic cover 23 from inside to outside. The anti-aging rubber soft cover 9 wraps part of the metal core rod 8 in the shape of a circular sleeve, and the anti-aging plastic cover 23 wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com