High-voltage motor stator winding end surface potential measurement system

A technology for stator windings and high-voltage motors, which is used in electrostatic field measurement, motor generator testing, and electrical measurement to achieve the effects of fast sampling rate, high accuracy, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

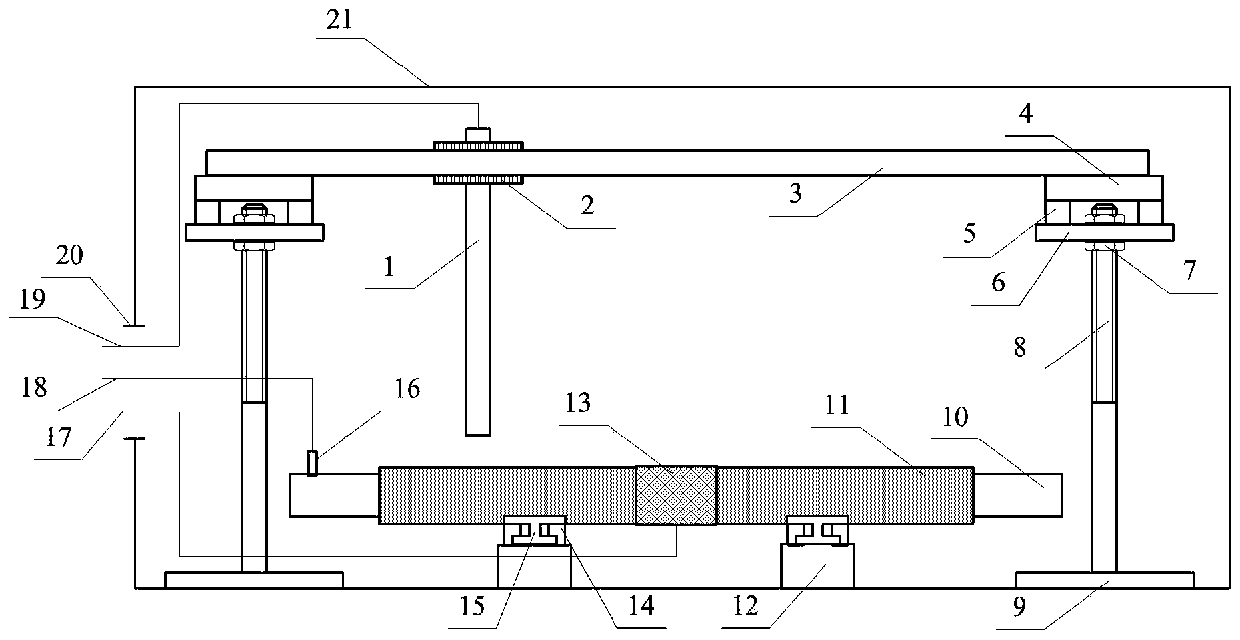

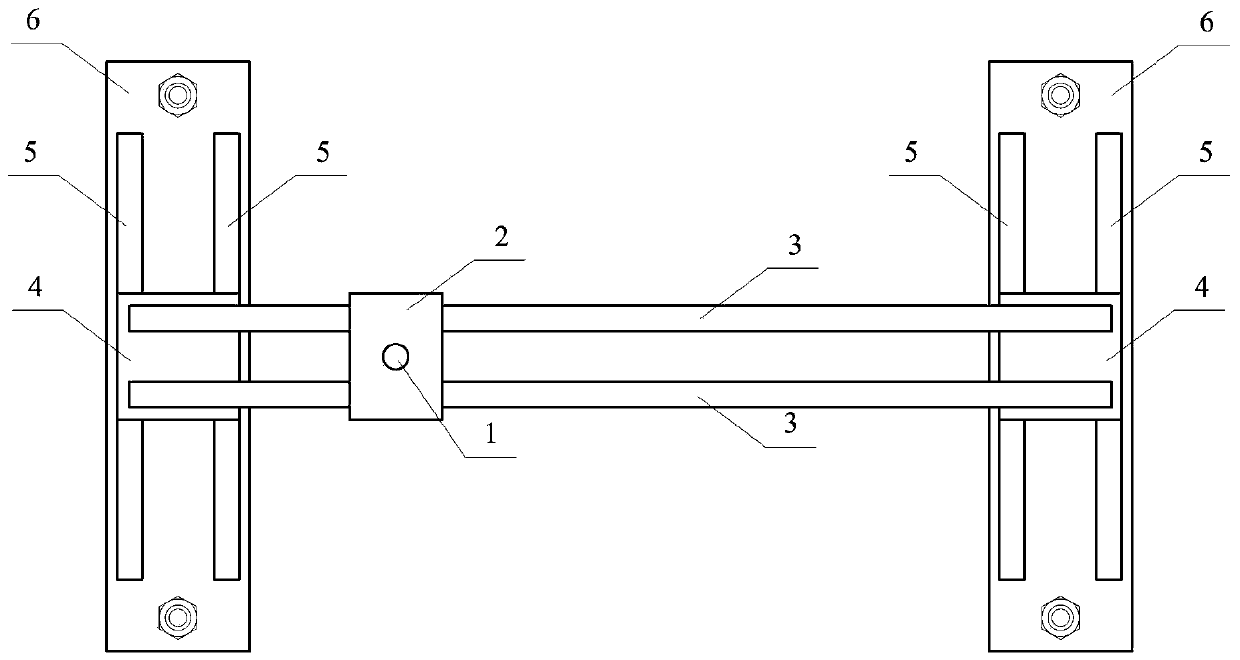

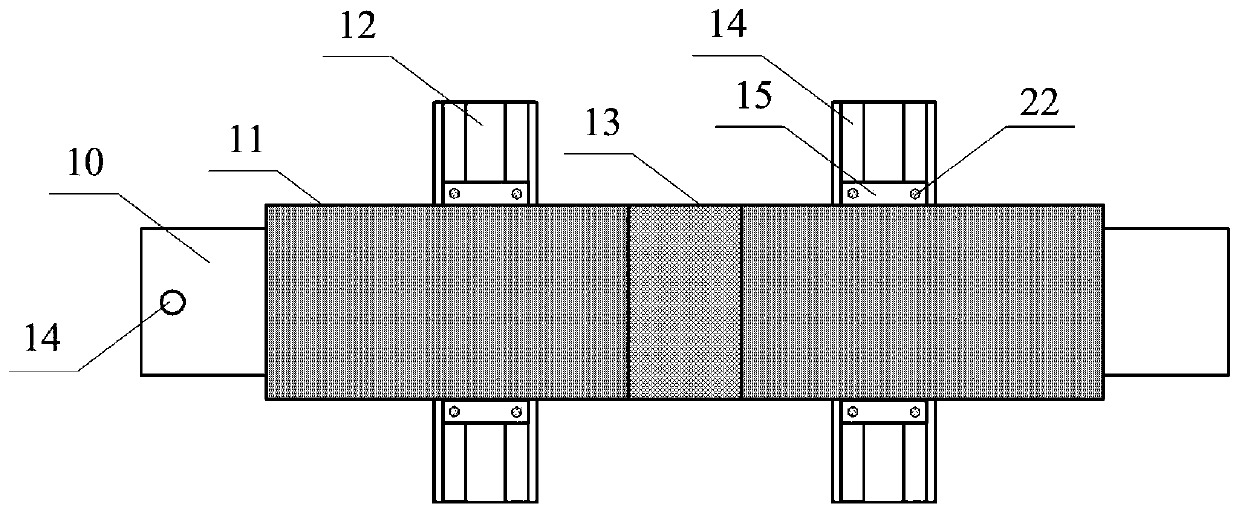

[0027] Combine figure 1 , figure 2 , image 3 with Figure 4 This embodiment is described. In this embodiment, a system for measuring the surface potential of the stator winding end of a high-voltage motor involved in this embodiment includes a high-voltage electrostatic probe 1, a probe support structure, a winding support structure, a high-voltage motor stator winding, The ground electrode 13, the high voltage electrode 16, and the constant temperature and humidity box 21. The high voltage electrostatic probe 1, the probe support structure, the winding support structure, and the high voltage motor stator winding are all located in the constant temperature and humidity box 21. The high voltage motor stator winding is composed of windings. The conductor 10 and the winding insulation layer 11 are composed of the winding insulation layer 11 wrapped in the middle of the motor winding conductor 10. The high voltage motor stator winding is fixed on the winding support structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com