Spraying room waste gas purification device

A technology of exhaust gas purification device and spray booth, which is used in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problem of exhaust gas being discharged into the atmosphere, and achieve the effect of prolonging service life, avoiding sliding and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

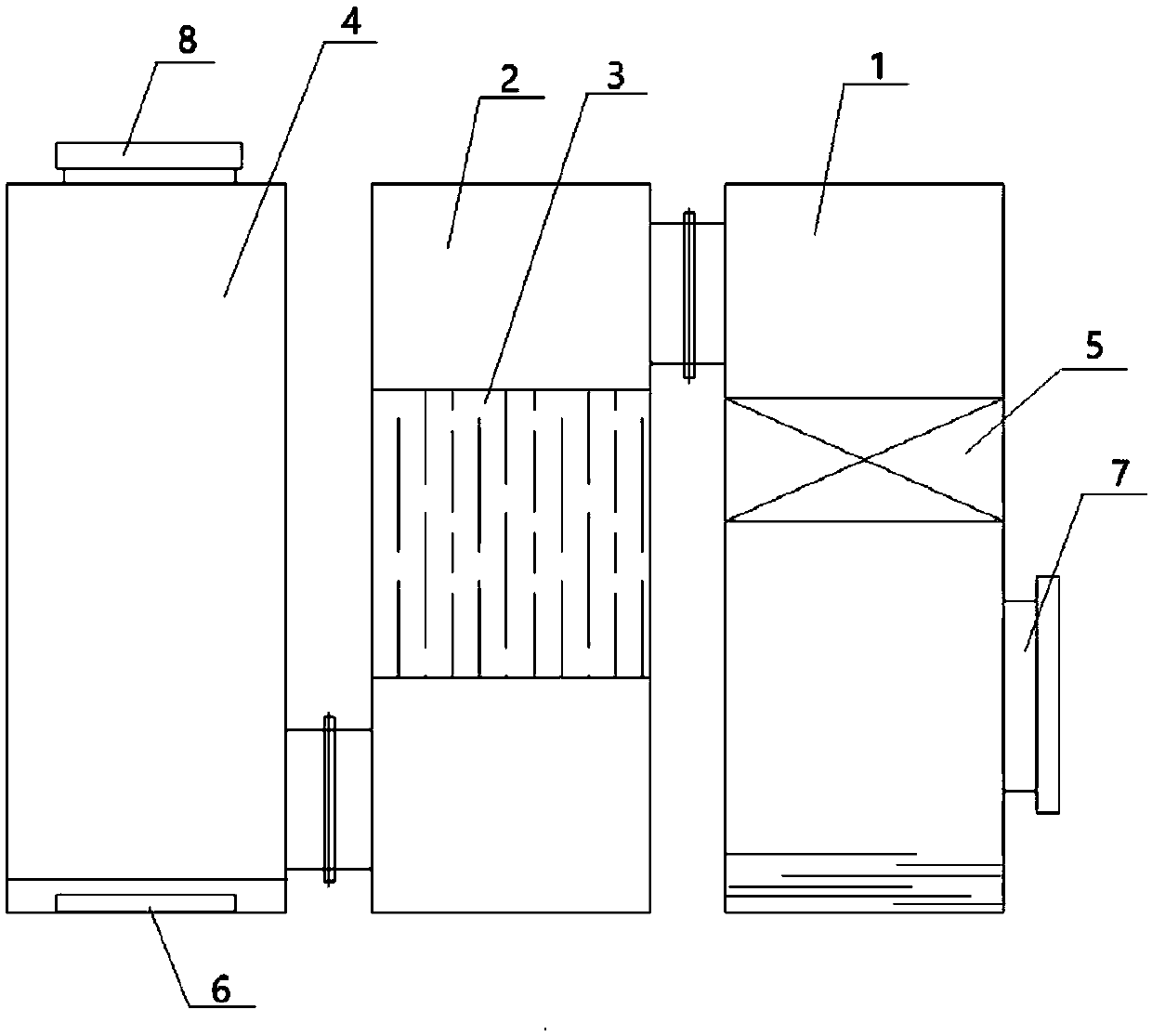

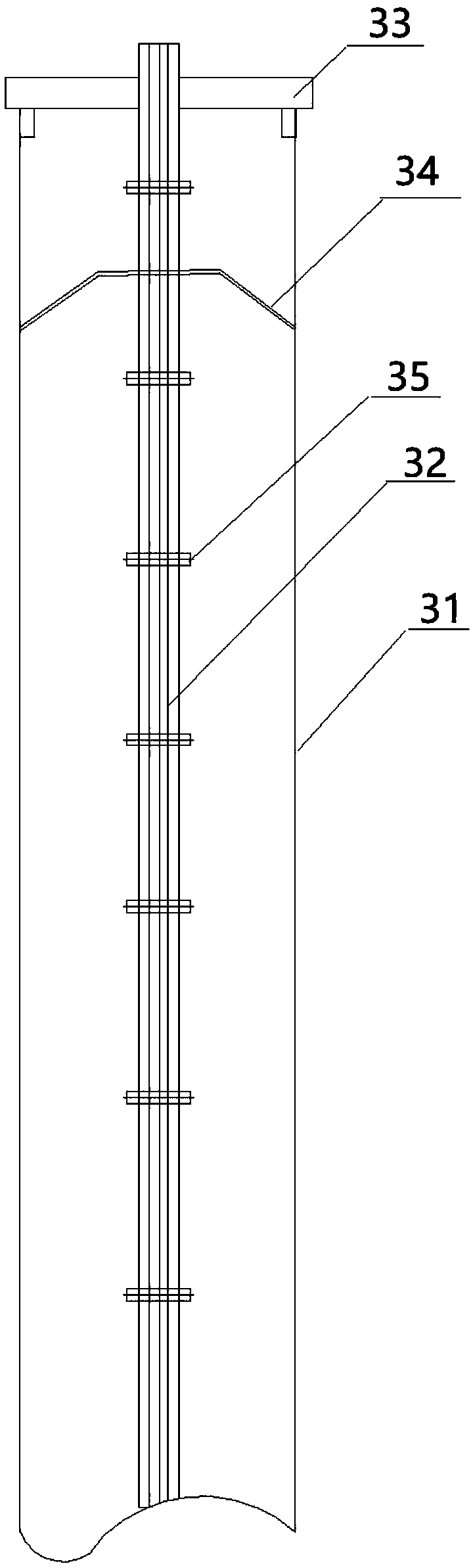

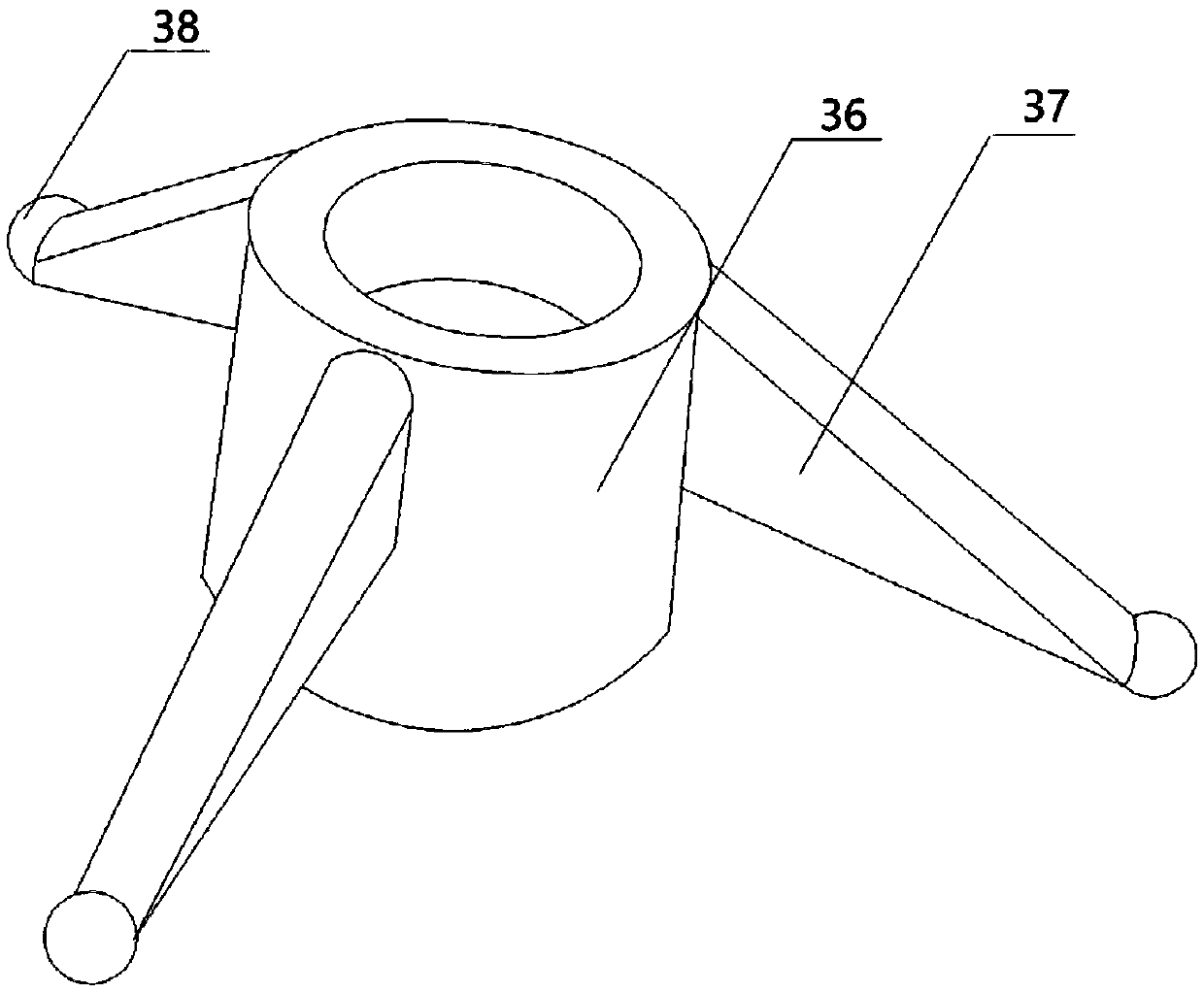

[0024] Such as figure 1 As shown, a spraying room exhaust gas purification device includes a pre-filter 1, a catalytic processor 2 and a post-processor 4 arranged in sequence. The pre-filter 1 is connected to the air inlet 7, and a filter screen 5 is arranged inside it, and the catalytic A plurality of plasma gas processing mechanisms 3 are arranged side by side in the processor 2. The plasma gas processing mechanism 3 includes a cylindrical electrode 31 and a plasma emitter 32. The plasma emitter 32 is connected to a high voltage, and the cylindrical electrode 31 is grounded. The bottom of 4 holds water and is provided with a heater 6 for heating the water, and the post processor 4 is connected to an exhaust port 8 . The bottom of the pre-filter 1 is filled with water. The water at the bottom of the pre-filter 1 can accommodate the large particles of impurities retained by the filter screen 5, preventing the entry of gas from bringing up the particles at the bottom of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com