Transmission device of diaphragm jigger

The technology of a transmission device and a jig machine is applied in solid separation, chemical instruments and methods, wet separation, etc., and can solve the problems of unsatisfactory movement and separation of fine-grained stainless steel slag, low product quality, and poor sorting effect. Achieve the effect of wide range of use, high product quality and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

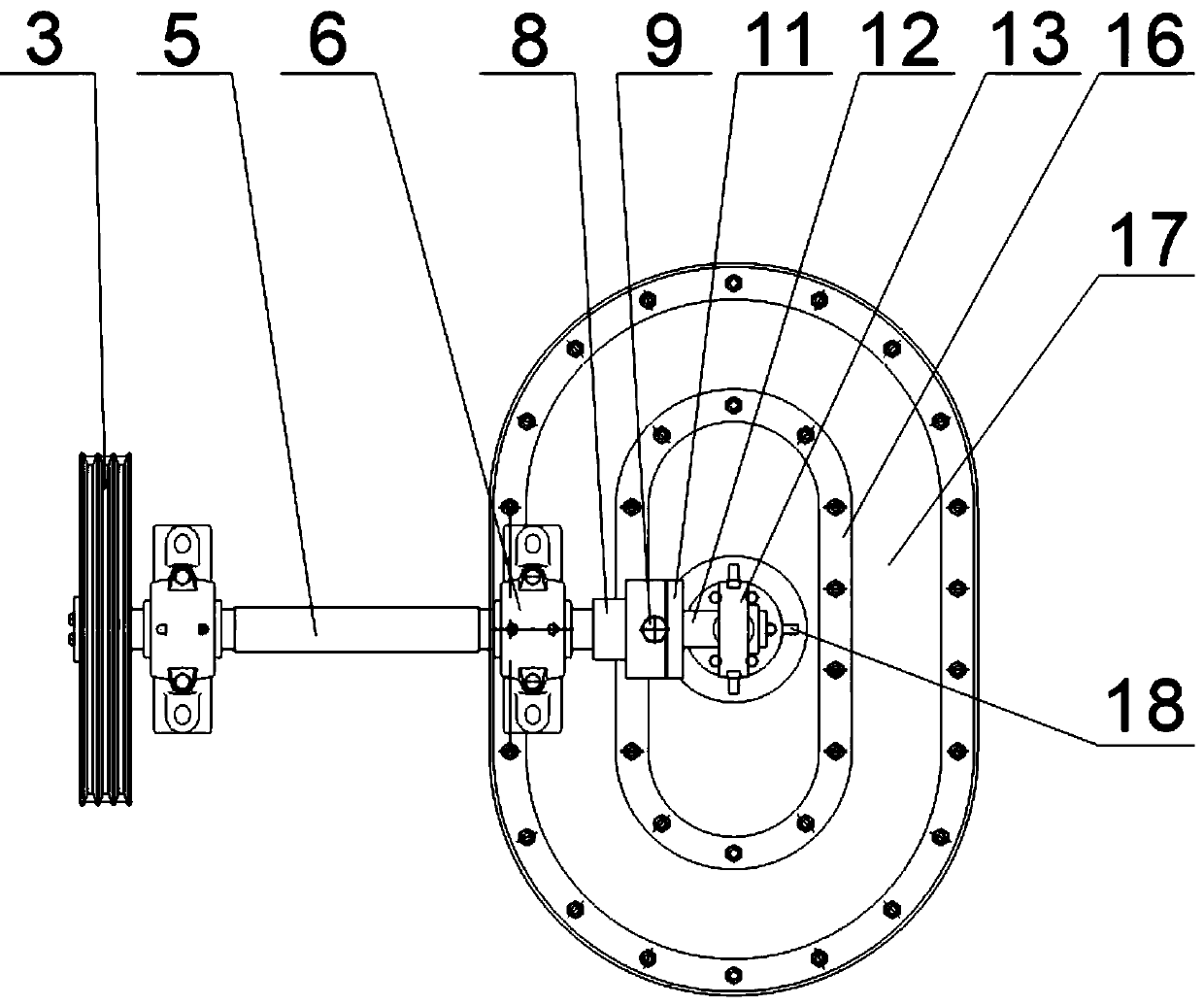

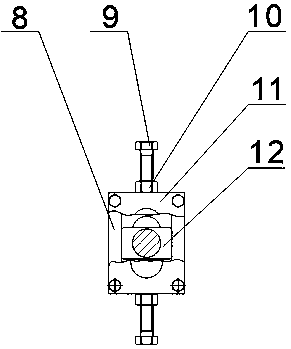

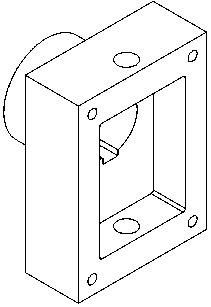

[0034] combined with Figure 1-8 As shown, a diaphragm jig transmission device of this patent includes a motor 1, a large pulley 3, a frame 4, two supporting bearing seats 6, a transmission shaft 5, a flat key 7, a coupling 8, and an eccentric shaft 12. Eccentric transmission mechanism 13, upper connecting rod 14, lower connecting rod 15 and pressure plate 16;

[0035] The output end of the motor 1 is connected with the large pulley 3 through the belt 2 to drive the large pulley 3 to rotate; two supporting bearing seats 6 are respectively arranged at the left and right ends of the frame 4; the transmission shaft 5 is arranged at the two supporting bearing seats 6 Inside, the left end of the transmission shaft 5 passes through the support bearing seat 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com