A platform reversible balance lifting arm

A lifting arm and reversible technology, which is applied in the field of platform reversible balance lifting arm, can solve the problems of easy to damage the aircraft fuselage, inconvenient single-person operation, high production cost, etc., to reduce the possibility of accidents, The effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

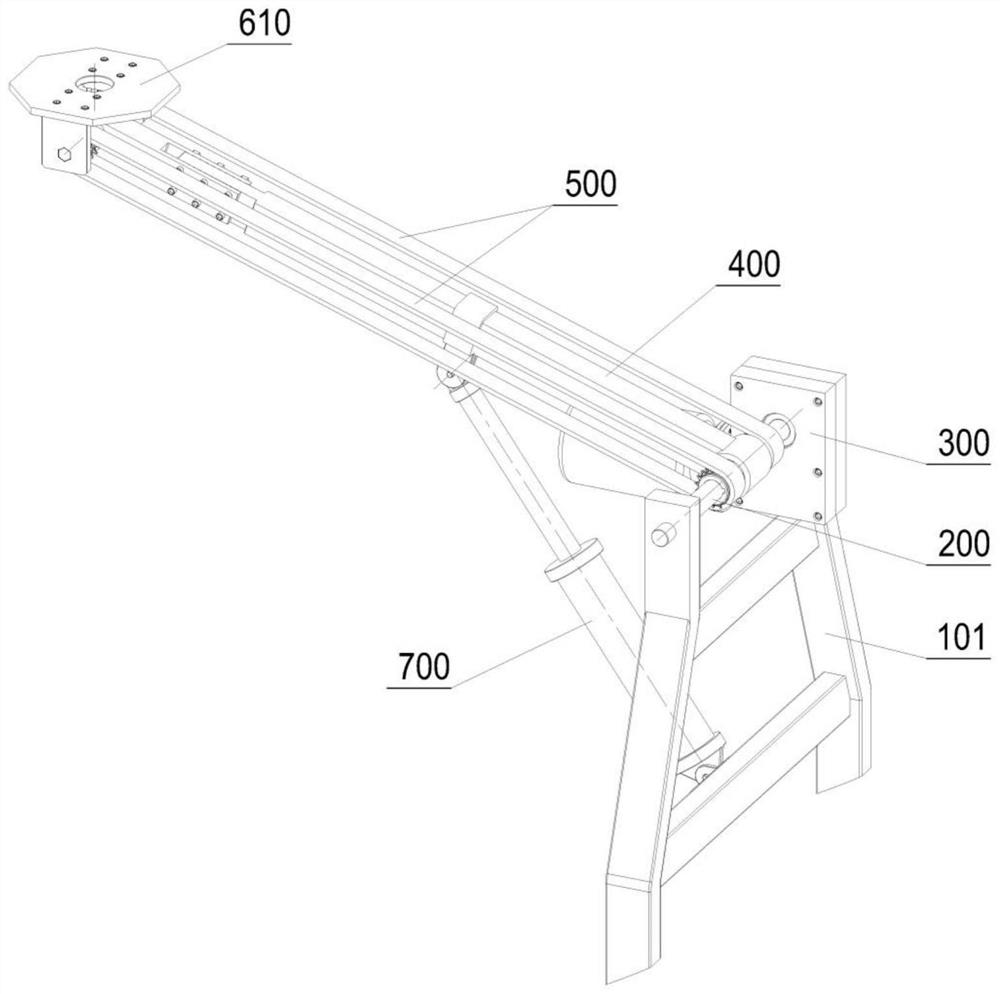

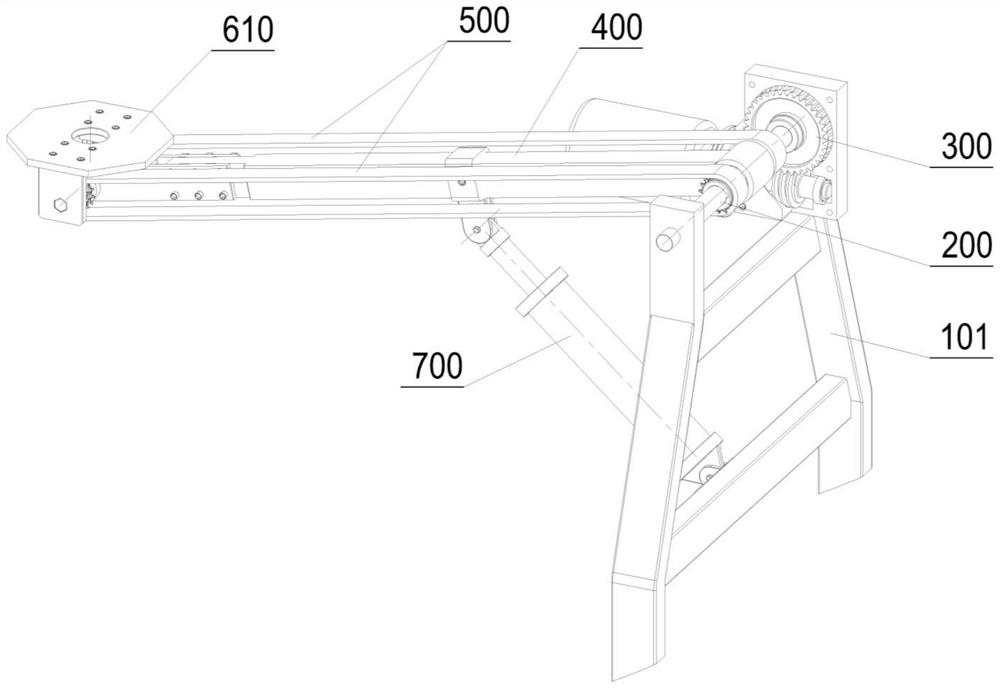

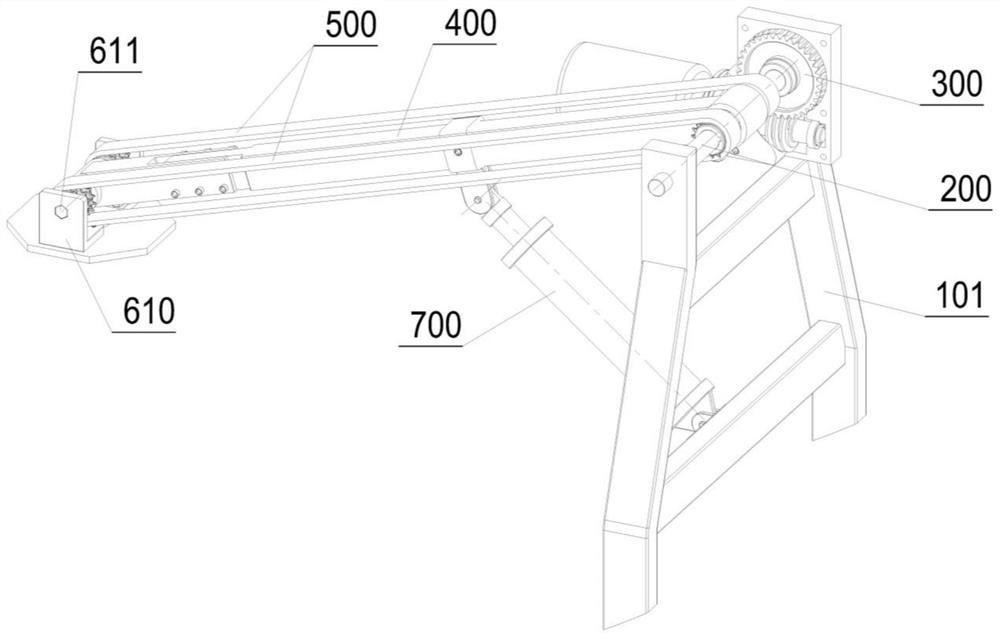

[0037] The present invention provides a platform reversible balance lifting arm, which includes a support device, a first transmission device, a main shaft 200, a lifting arm 400, a second transmission device, a lifting platform 610 and a lifting cylinder 700, and the main shaft 200 rotates Connected to the support device, one end of the lifting arm 400 is rotationally connected to the main shaft 200, the other end is connected to the lifting platform 610, one end of the second transmission device is connected to the main shaft 200, and the other end is connected to the lifting platform 610, One end of the lifting cylinder 700 is movably connected with the supporting device, and the other end is movably connected with the lifting arm 400 .

[0038] The first transmission device drives the main shaft 200 to rotate, the rotation of the main shaft 200 drives the second transmission device to move, the second transmission device drives the lifting platform 610 to rotate, and the li...

Embodiment 2

[0047] In this embodiment, other devices except the lifting platform 610 in the mobile trolley frame 110 and the missile lifting platform 600 are added relative to the first embodiment, and the remaining parts in this embodiment are the same as in the first embodiment.

[0048] See attached Figure 6 to attach Figure 9 As shown, the mobile trolley frame 110 is made up of the undercarriage 102, the handrail 103, the front wheel 104, the rear wheel 105 and the like. The missile lifting platform 600 consists of a lifting platform 610, a horizontal rotating arm 620, a horizontal rotating platform 630, two sets of guide rail slider pairs 640, a square tube support plate 650, a square tube 660, two sets of missile rollers 670 and two sets of pneumatic missiles. Claw is taken mechanism 680 etc. to form.

[0049] This device is also installed control box 120, power supply 130, air compressor 140, gas storage tank 150 on mobile trolley frame 110. The control box 120 is used to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com