A fiber-based microporous structure and its preparation method

A structure, fiber-based technology, applied in the field of fiber-based microporous structure and its preparation, can solve the problems of natural environment and biological hazards, and achieve the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Concrete preparation steps are:

[0048] 1) Mix the adhesive and water together according to the above ratio, use heating, preferably in a water bath, the temperature of the water bath is 65°C-95°C, stir continuously until the adhesive is completely dissolved, take it out and stand it at ambient temperature for later use, ambient temperature 23 ±2°C.

[0049] 2) Heat and pre-expand the heat-expandable particles to about 30%-70% of the optimal expansion size. According to the expansion temperature of the microspheres, you can choose water bath heating expansion, oven heating expansion, hot steam expansion or extruder heating expansion.

[0050] Among them, the heat-expandable particles are also called Yangbuck powder, expansion agent, and microcapsule foaming agent. They are tiny spherical particles. The particles are composed of a polymer shell and the gas wrapped in it. , the thermoplastic shell softens, the gas inside the shell expands, and the particle volume change...

Embodiment 1

[0057] A fiber-based microporous structure, the preparation method steps are as follows:

[0058] (1) Mix 6 parts of polyvinyl alcohol and 20 parts of water together, heat in a water bath at a temperature of 85°C, stir continuously until the polyvinyl alcohol is completely dissolved, take it out and place it at ambient temperature for 30 minutes for later use.

[0059] (2) Take 0.5 parts of heat-expandable particles and put them in a water bath environment for pre-expansion. The initial expansion temperature is 80-85°C, and the maximum heat-resistant temperature is 125-130°C. Use a water bath to pre-foam the microspheres. The water bath temperature is 85 ℃, heating and pre-expanding for 10 minutes to about 40% of the optimal expansion size.

[0060] (3) Get 15 parts of bleached wood pulp sheets and hydrobeat until the fibers are completely loosened, the beating concentration is 5%, and the moisture content of the fibers after water filtration is 70% (35 parts of water)

[006...

Embodiment 2

[0066] This embodiment is improved on the basis of Embodiment 1.

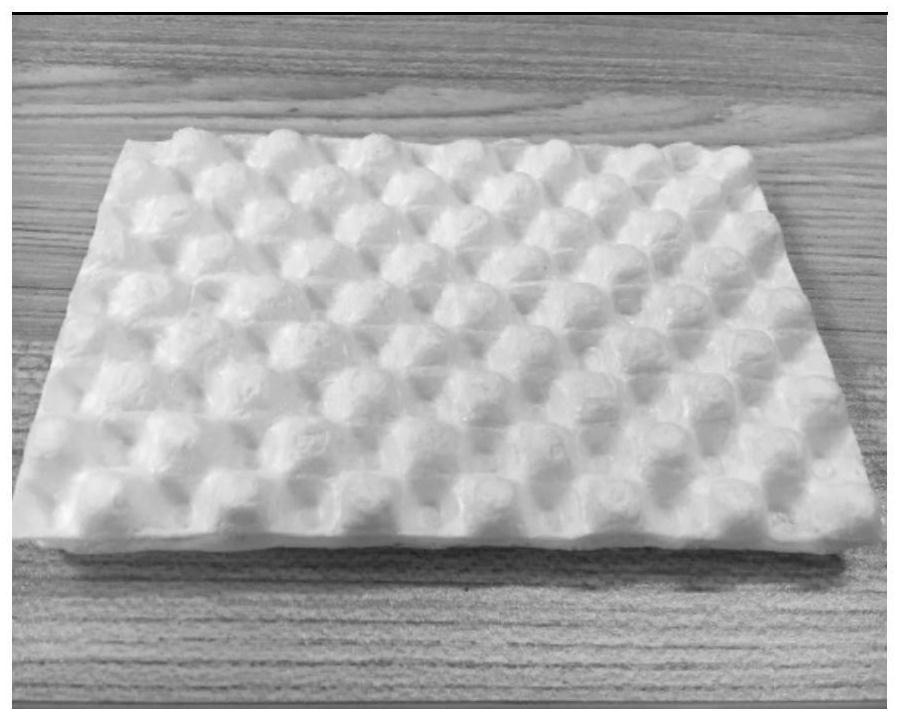

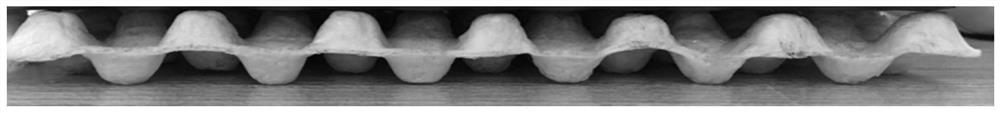

[0067] Steps (1) to (5) are the same as those in Example 1, only step (6) is: fill the slurry obtained in step (5) into a corrugated mold at a temperature of 130°C and a pressure of 0.5 MPa, and continue heating After 45s, a fiber-based microporous structure with a structural thickness (the distance from the peak to the trough of the sample) of 12mm was obtained. This example has the same formula and process as Example 1, and the mechanical properties of the base material are unchanged. For the specific sample structure, see attached figure 1 And attached figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com