Method for monitoring air particles and air abnormal components in switch cabinet

An abnormal composition, internal air technology, applied in particle suspension analysis, suspension and porous material analysis, measurement devices, etc. Infiltration of dust particles and other problems, to avoid insulation breakdown, avoid insulation flashover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

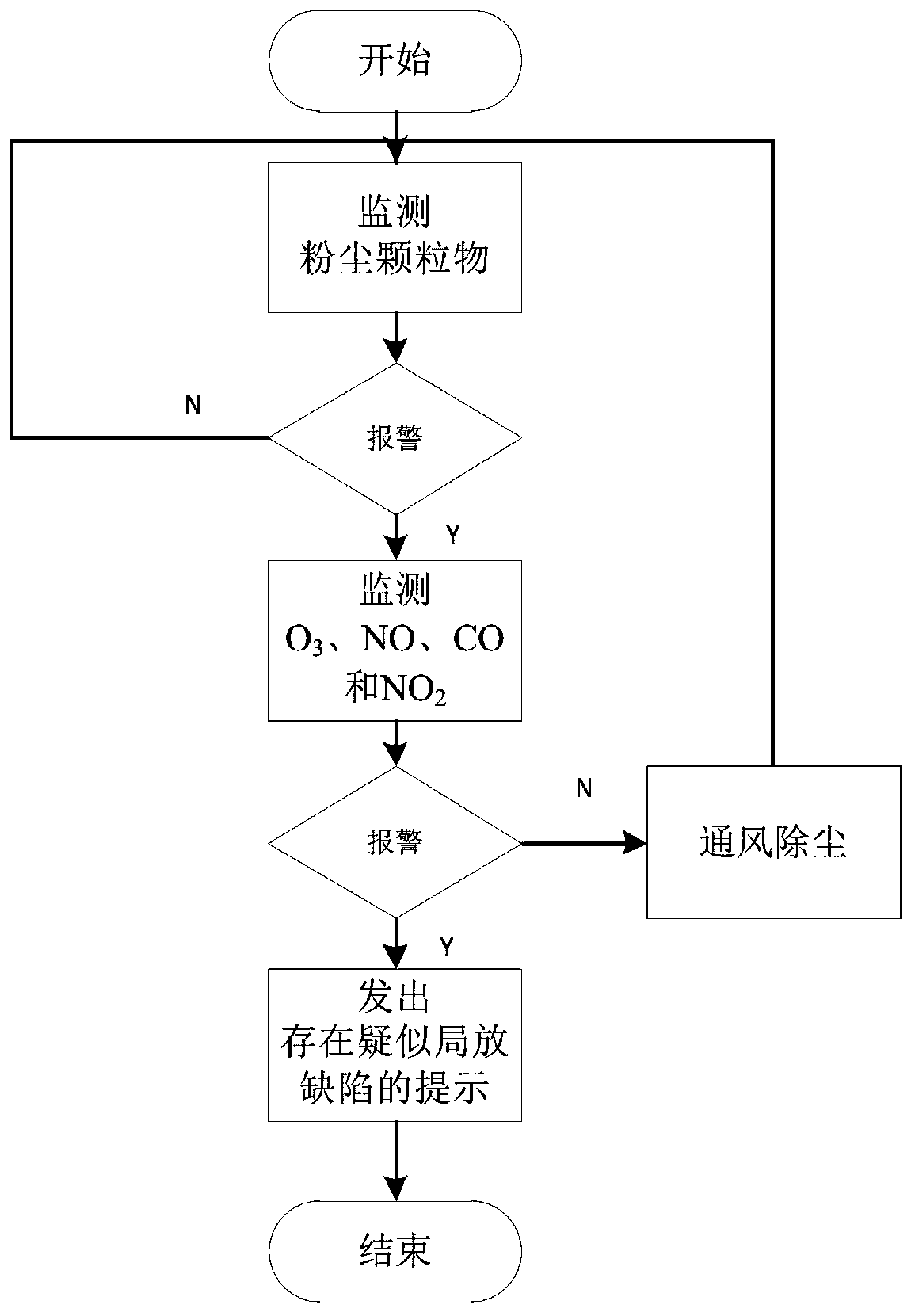

[0022] A method for monitoring air particles and abnormal air components inside a switchgear, such as image 3 shown, including the following steps:

[0023] Step 1. Monitor the dust particles inside the switchgear, and judge whether the concentration of dust particles reaches the alarm value. If it reaches the alarm value, alarm and go to step 2, otherwise go to step 5.

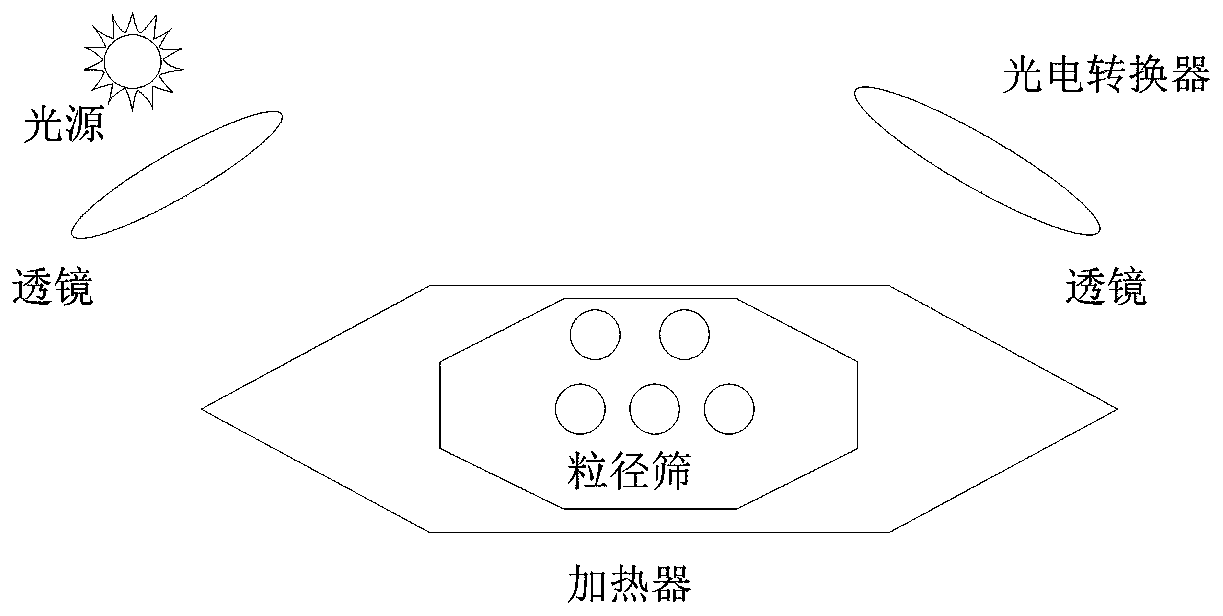

[0024] In this step, the infrared light scattering dust fall monitoring device using the particle calculation principle is used to monitor dust particles, and the infrared light scattering dust fall monitoring device is as follows: figure 1 As shown, it includes a particle size sieve, a light source, a heater, a light-transmitting mirror, and a photoelectric converter. The working process is as follows: the heater makes the dust particles generate a natural rising airflow through heating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com