Industrial automation defect detection method based on deep learning

A technology for industrial automation and defect detection, applied in neural learning methods, image data processing, instruments, etc., to achieve good detection accuracy, improve image detection accuracy and stability, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

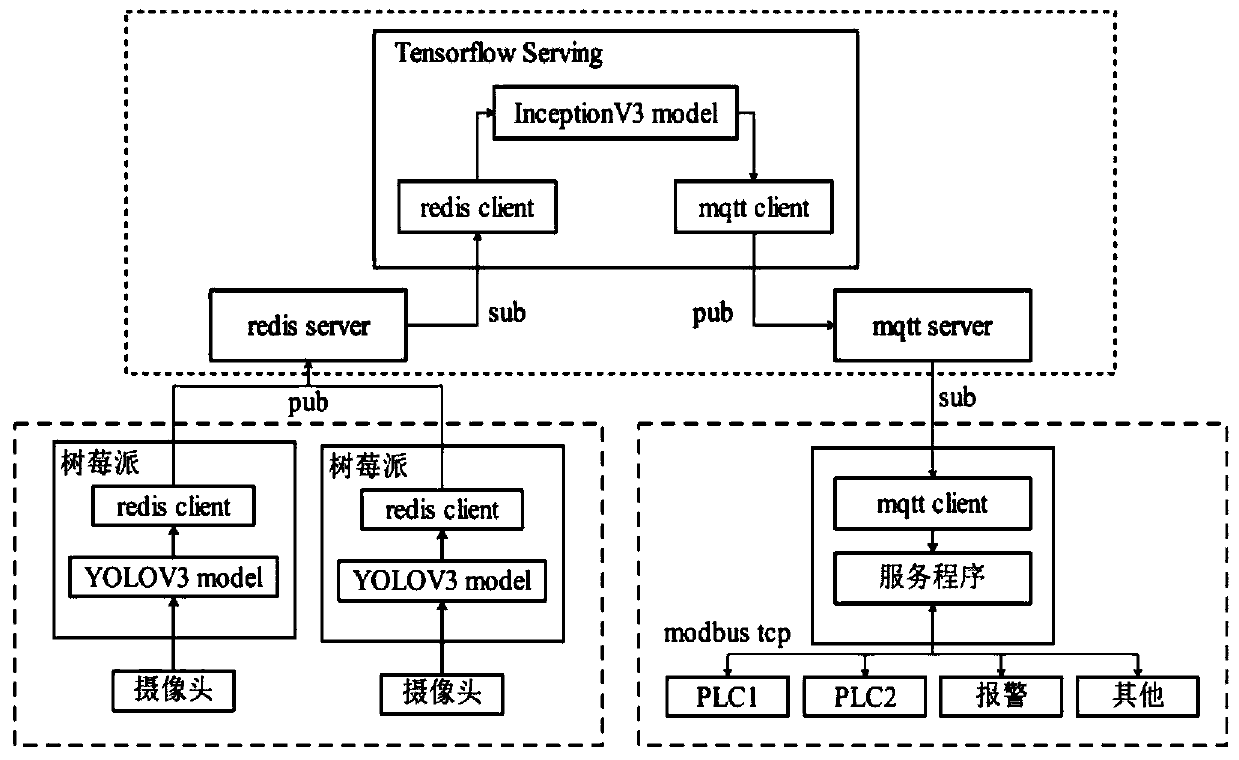

[0037] In order to overcome the deficiencies of the above-mentioned prior art, the present invention provides an industrial automation defect detection method and system based on deep learning, which avoids complicated feature extraction work, and has high accuracy and good generalization ability , which shows advantages when the proportion of defects is small and the detection background is complex. In the case of insufficient sample data, it can quickly train an applicable defect detection model, support rapid hot deployment, and achieve better detection results than traditional detection methods. The detection system is a modular structure system based on gRPC and MQTT, which is easy to deploy and can be applied to high-concurrency industrial application scenarios.

[0038] The technical solution adopted in the present invention is: an industrial automation defect detection method and system based on deep learning, comprising the following steps:

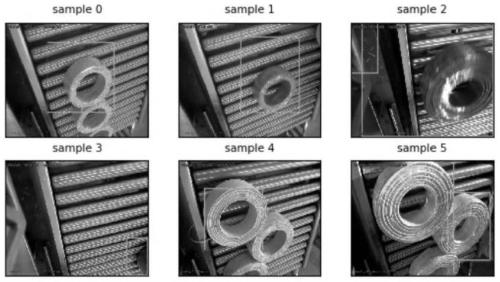

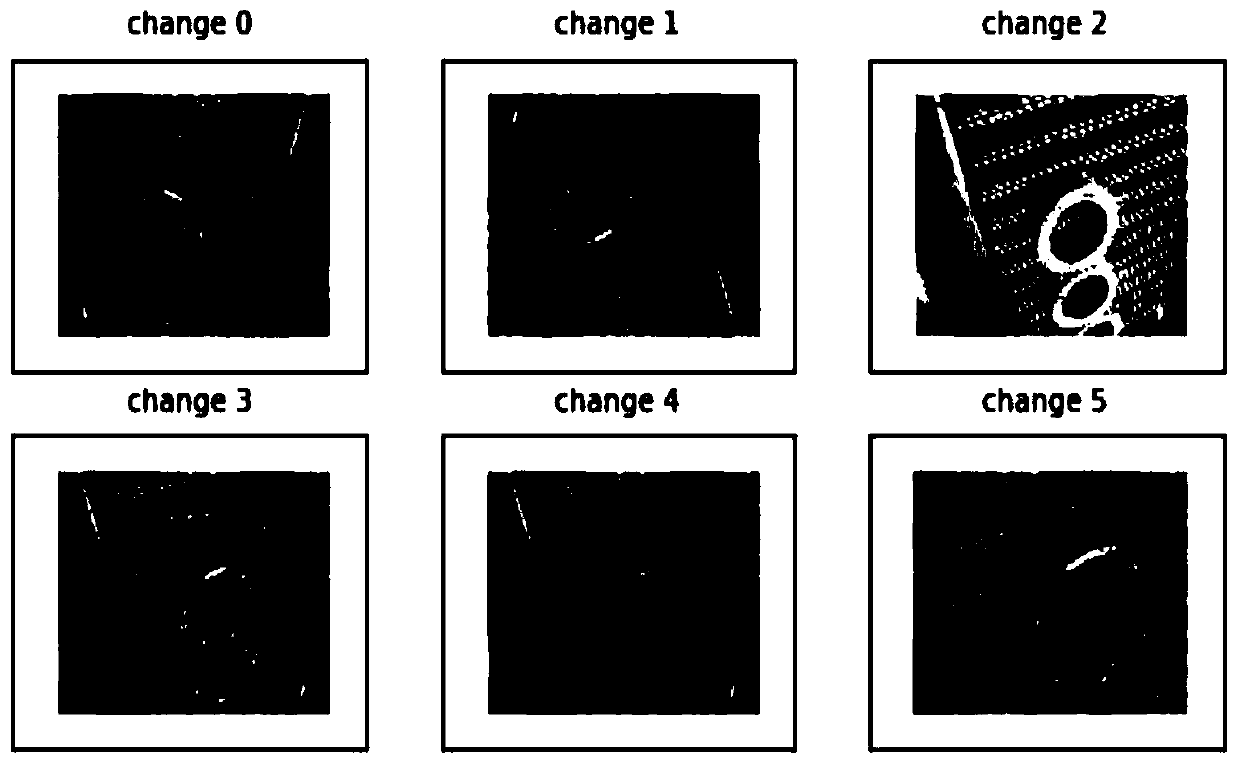

[0039] (i): The Raspberr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com