Industrial CT defect detection method based on deep learning

A defect detection and deep learning technology, applied in image data processing, instruments, computing, etc., can solve the problems of increased production cost, time-consuming, poor model accuracy, etc., to reduce production costs and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

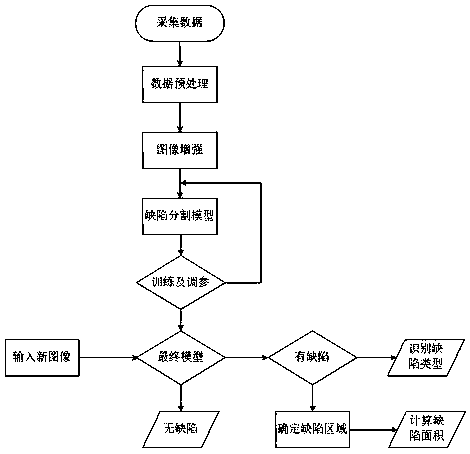

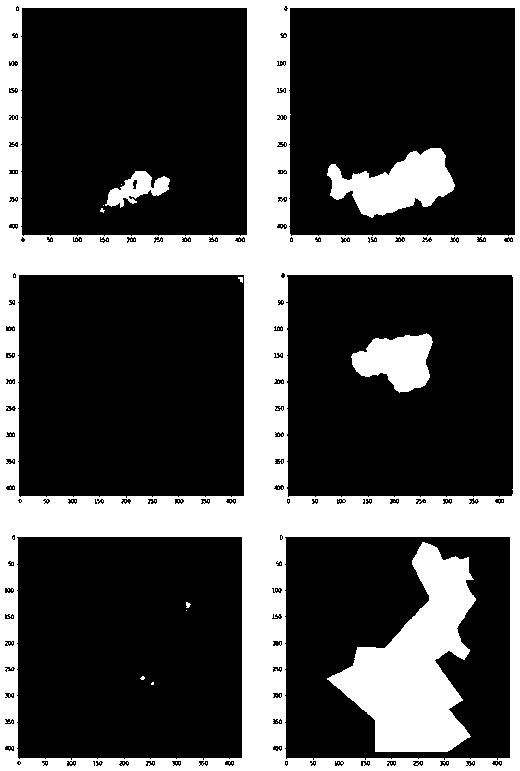

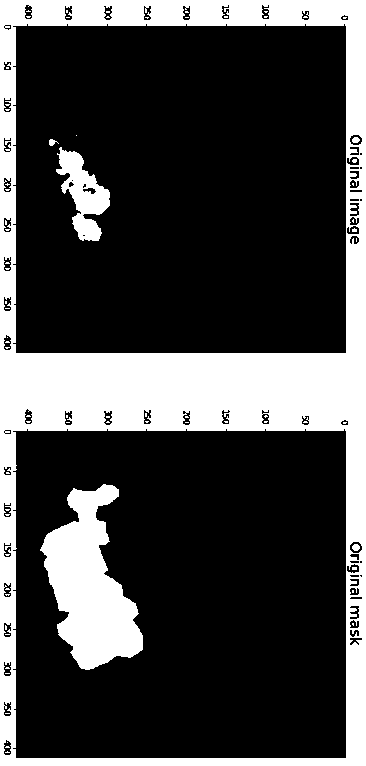

[0030] Such as Figure 1-6 As shown, an industrial CT defect detection method based on deep learning, which includes the following steps:

[0031] Step 1. Collecting data: First, collect 3D images of equipment parts through industrial CT, and select 2D images with or without defects after slices as model data;

[0032] Step 2. Divide the data set: Divide the data obtained in step 1 into three parts: training set, verification set, and test set according to a certain proportion. At the same time, the data set is shuffled so that each part contains the same proportion of defective images. The data is used as the basic data for model training, the verification set is used to test the model and fine-tuned, and the test set is used as the final verification standard of the model;

[0033] Step 3. Image labeling: mark the training set and verification set images in step 2, and obtain the masks corresponding to four types of defects: holes, impurities, slag holes, and pinholes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com