Intelligent safe high-voltage single-core cable

A single-core cable, high-voltage technology, used in insulated cables, power cables, power cables including optical transmission components, etc., can solve problems such as failure to meet safety requirements, poor air circulation, safety accidents, etc., to achieve convenient cable connection, The effect of high safety performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

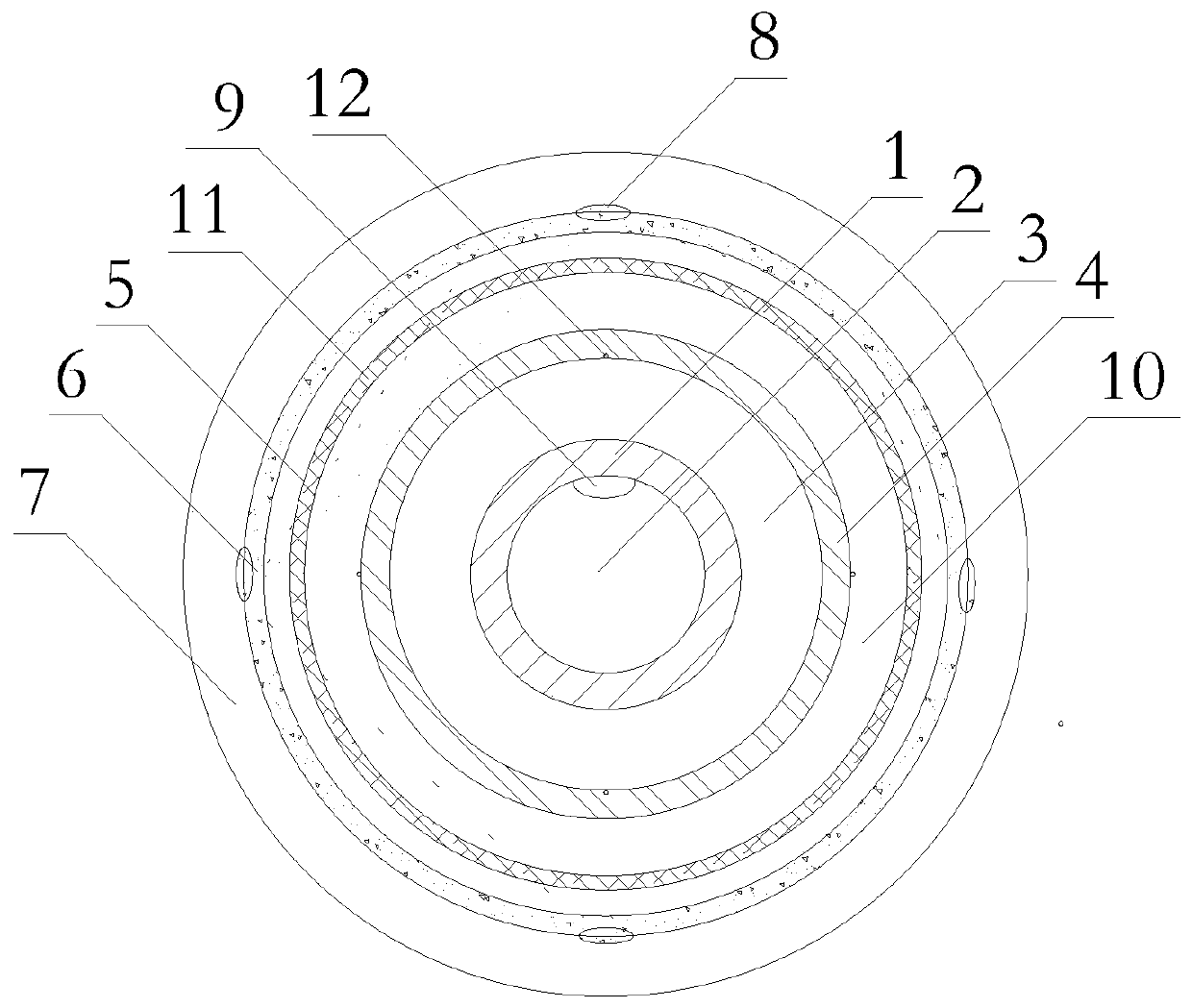

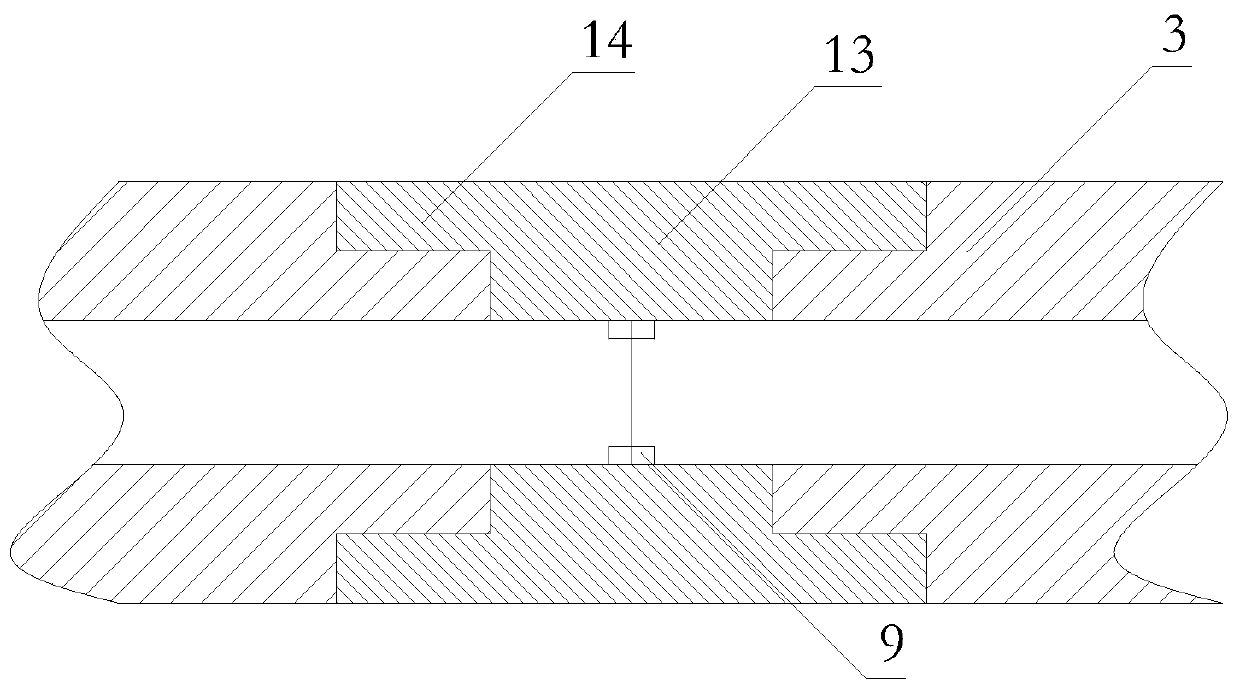

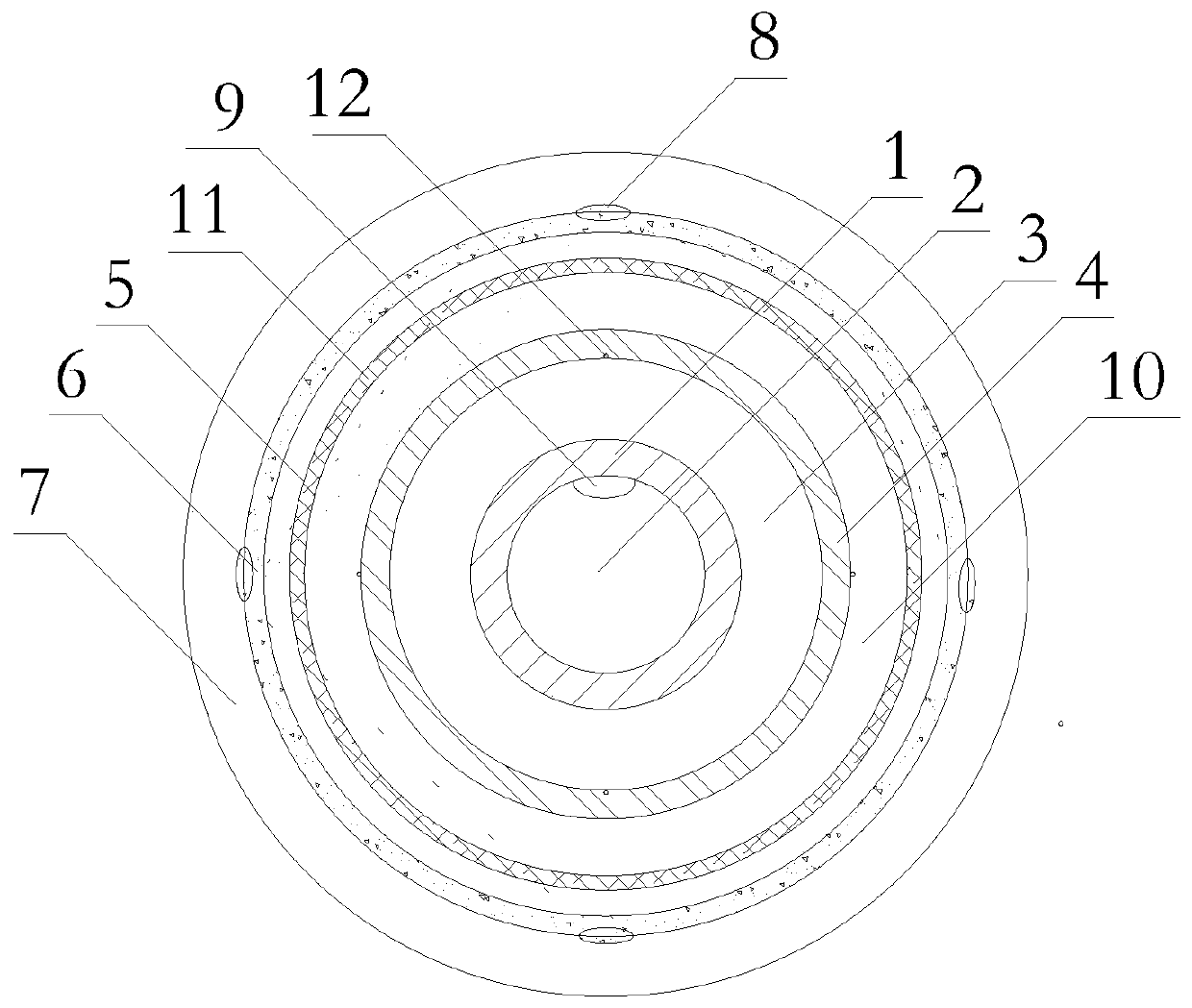

[0029] Such as figure 1 As shown, an intelligent and safe high-voltage single-core cable includes a conductor core 1, the interior of the conductor core 1 is hollowly provided with a heat dissipation channel 2 along the axis, and the outer surface of the conductor core 1 is covered with a volume resistance rate not less than 10 16 An insulating layer 3 of Ω·cm, the outer surface of the insulating layer 3 is covered with a metal shielding layer 4, and the outer surface of the metal shielding layer 4 is provided with a longitudinal water-blocking buffer layer 5, and the longitudinal water-blocking buffer layer 5 An anti-corrosion layer 6 is provided on the outer surface of the anti-corrosion layer 6, and a sheath lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com