A DC Bias Flux Inversion Permanent Magnet Motor

A magnetic flux reversal and permanent magnet motor technology, applied in the direction of motors, magnetic circuits, electric components, etc., can solve the problems of reducing the reliability of motor fault operation, increasing the effective air gap of the motor, and increasing the short-circuit current of the motor, so as to reduce demagnetization risk, increasing motor efficiency, effect of increasing inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

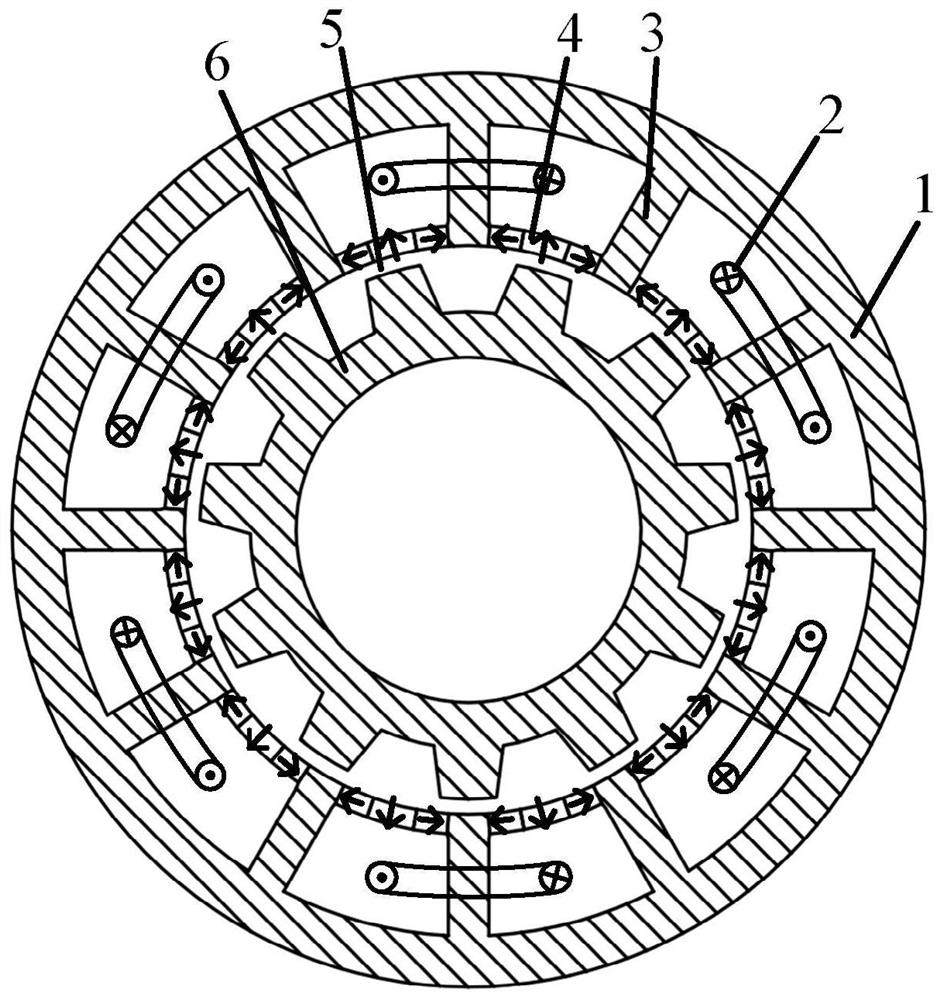

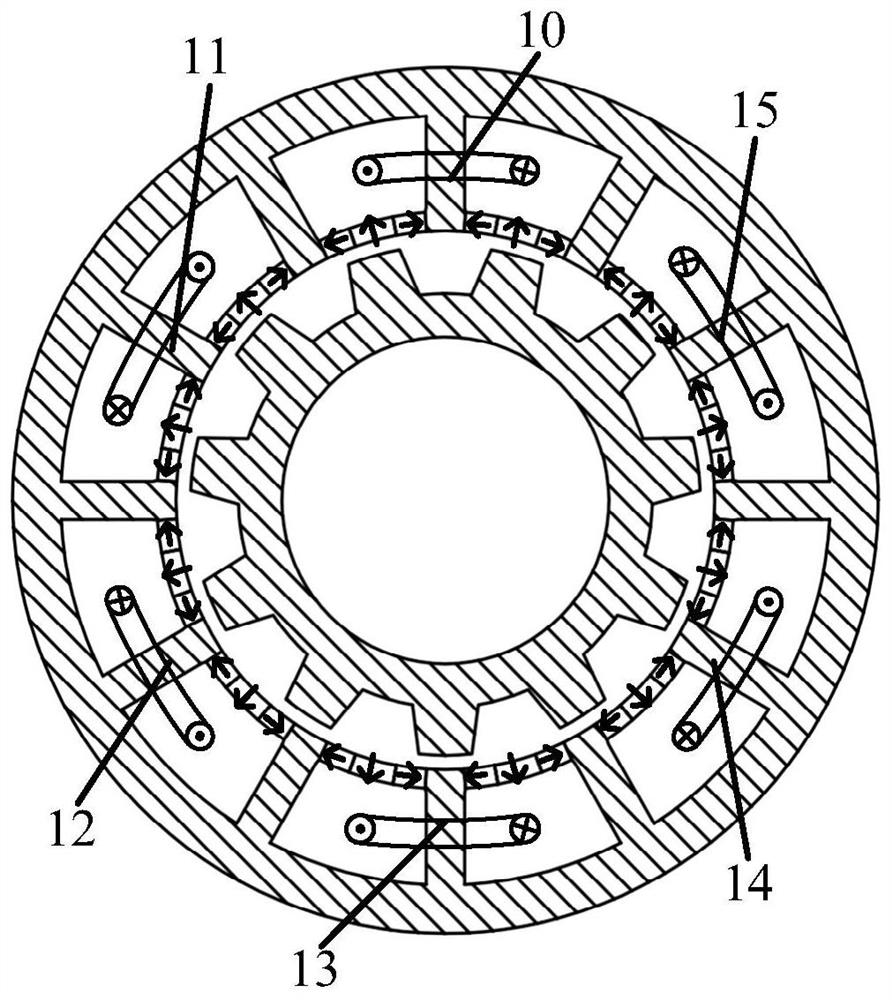

[0037] like figure 1 As shown, the present invention designs a DC bias type magnetic flux reverse permanent magnet motor, including a permanent magnet type stator 1 and a male core rotor 6, and the permanent magnet type stator 1 is formed between the male core rotor 6. The independent air gap 5, the permanent magnet type stator 1 includes a stator yoke portion and a plurality of stator teeth 3, a stator yoke portion forms a plurality of stator grooves in a plurality of stator teeth 3, which is fixed in the groove in the grooves, and injected into the armature winding 2 The biased DC current is provided with a permanent magnet 4 at the groove of each stator slot, the permanent magnet to form a pair of magnetic poles, and the number of permanent magnets at each stator trough. same.

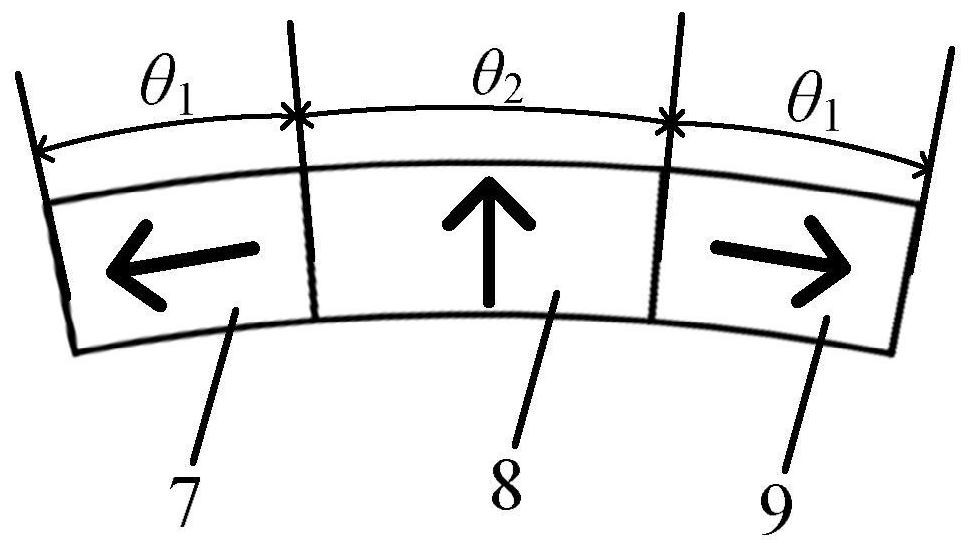

[0038] like figure 2 As shown, there are 3 pieces of permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com