Planar diaphragm loudspeaker of magnetic reflux structure based on annular magnet

A technology of planar diaphragm and ring magnet, which is applied in the field of loudspeakers, can solve the problems of low production capacity and manufacturing efficiency, difficult to effectively reduce, thick and poor sense of density, etc., to improve dynamic control capabilities, reduce manufacturing costs, and improve sound production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

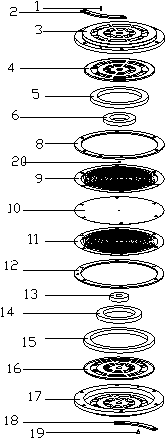

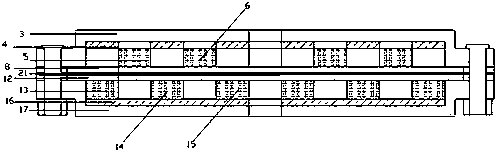

[0092] On the basis that the magnets on the ring and the magnets under the ring are arranged in a staggered manner, the sizes of the magnets on the ring and the magnets under the ring are exactly the same.

[0093] like figure 1 and figure 2 As shown, the upper magnet group includes two ring upper magnets, and the lower magnet group includes three ring lower magnets, wherein the ring upper magnets and the ring lower magnets are alternately arranged. A plurality of gaps are formed between the magnets on the adjacent rings, and the magnets under the rings are arranged facing the gaps.

[0094] (B) Asynchronous asymmetric formula:

[0095] On the basis of the staggered arrangement of the magnets on the ring and the magnets below the ring, the dimensions of the magnets on the ring and the magnets below the ring meet the following conditions:

[0096] The inner diameters of the magnets on the ring and the magnets under the ring are the same, and the outer diameters and heights ...

Embodiment 2

[0108] [Example 2] Peer-to-peer full alignment

[0109] The number of magnets on the ring is the same as that of the magnets under the ring, and on the basis of equal settings, the magnets on the ring and the magnets under the ring have exactly the same size.

[0110] like Figure 4 and Figure 5 As shown, the upper magnet group includes 3 ring upper magnets, and the lower magnet group includes 3 ring lower magnets, and each ring upper magnet and ring lower magnet form a group, and each group of ring upper magnets and ring The centerlines of the vertical sections of the lower magnet lie on the same line. Moreover, the inner and outer diameters and heights of the magnets on each ring and the magnets below the ring are consistent.

Embodiment 3

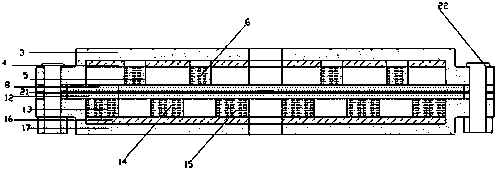

[0111] [Example 3] Alignment within peers

[0112] The number of magnets on the ring and the magnets under the ring are different, and on the basis of equal settings, the magnets on the ring and the magnets under the ring are exactly the same in size.

[0113] like Figure 7 and Figure 8 As shown, the upper magnet group includes: the third ring upper magnet 7 and the second ring upper magnet 6 from the inside to the outside, and the lower magnet group includes: the first ring lower magnet 13 from the inside to the outside, and the second ring lower magnet 6. Magnet 14 and magnet 15 under the third circular ring. Wherein, the magnet 7 on the third ring is set correspondingly with the magnet 13 under the first ring, the magnet 6 on the second ring is set correspondingly with the magnet 14 under the second ring, and the magnet 15 under the third ring has no corresponding ring On the magnet, the opposite is empty.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com