Compatible with thyristor dimmer without flicker led drive circuit

A technology of LED driver and dimmer, applied in electrical components and other directions, can solve the problems of stroboscopic output and low efficiency, and achieve the effect of balanced input and output power and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

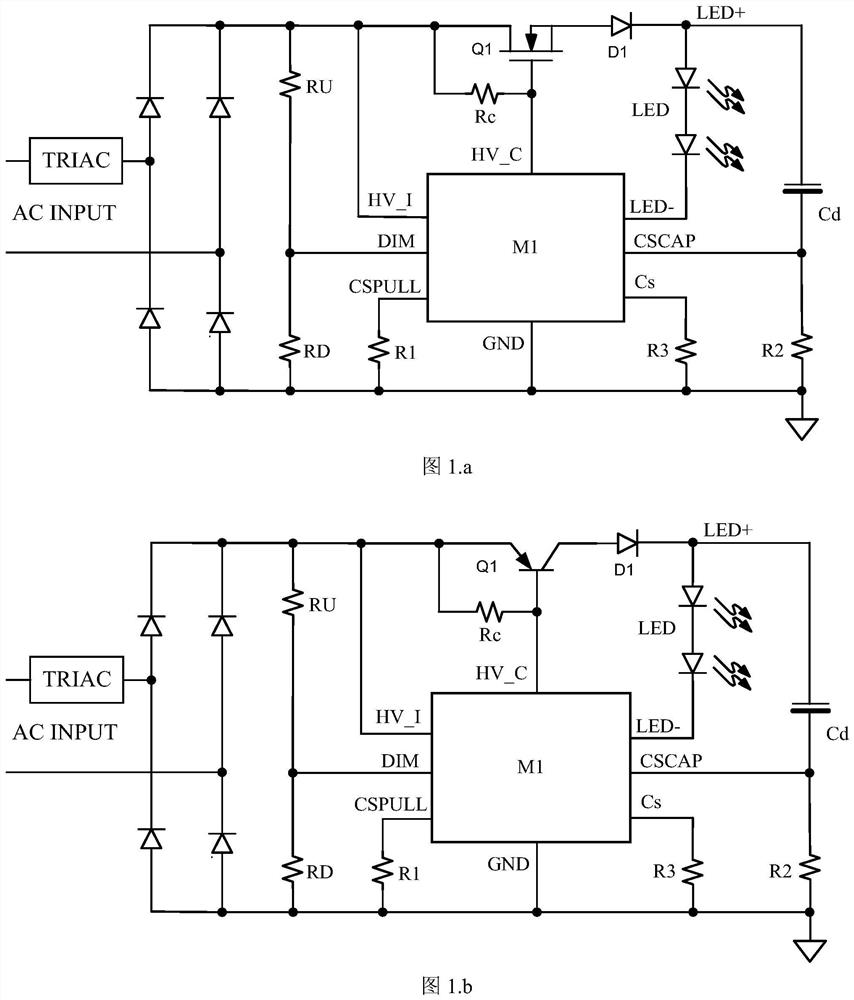

[0049] Embodiment 1. A non-flicker-free LED drive circuit compatible with thyristor dimmers, using a power MOS tube as an external power device Q1, such as figure 1 as shown in .a;

[0050] The flicker-free LED drive circuit compatible with thyristor dimmers includes a rectifier bridge, a functional block M1, an external power device Q1, an external ground-to-ground voltage divider network composed of resistors RU and RD connected in series, an isolation diode D1, and an electrolytic capacitor Cd. Charging current detecting resistor R2 (referred to as detecting resistor R2), LED load string, LED output current detecting resistor R3 (referred to as detecting resistor R3).

[0051] The mains power is supplied to the rectifier bridge through the thyristor dimmer TRIAC, the output voltage negative terminal of the rectifier bridge is connected to the ground, and the output voltage positive terminal of the rectifier bridge is respectively connected to the following components: an ex...

Embodiment 2

[0089] Embodiment 2, using a power PNP transistor as an external power device Q1 ( figure 1 .b)

[0090] The positive terminal of the output voltage of the rectifier bridge is respectively connected to the following components: an external voltage divider network composed of resistors RU and RD in series, the HV_I pin of the functional block M1, the HV_C pin of the functional block M1 after passing through the Rc resistor, and the external power device The emitter of Q1 ( figure 1 .b); The collector of the external power device Q1 is connected to the anode of the isolation diode D1;

[0091] The base of the external power device Q1 is connected to the HV_C pin of the functional block M1 and the Rc resistor;

[0092] The rest are equal to the above "a".

[0093] That is, compared with Embodiment 1 in Embodiment 2, Q1 is replaced by a PNP transistor instead of an N MOSFET in Embodiment 1. Due to the driving characteristics of the PNP transistor, the corresponding drive circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com