High-safety cutting device for production of communication equipment shell

A technology of communication equipment and cutting device, applied in metal processing and other directions, can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

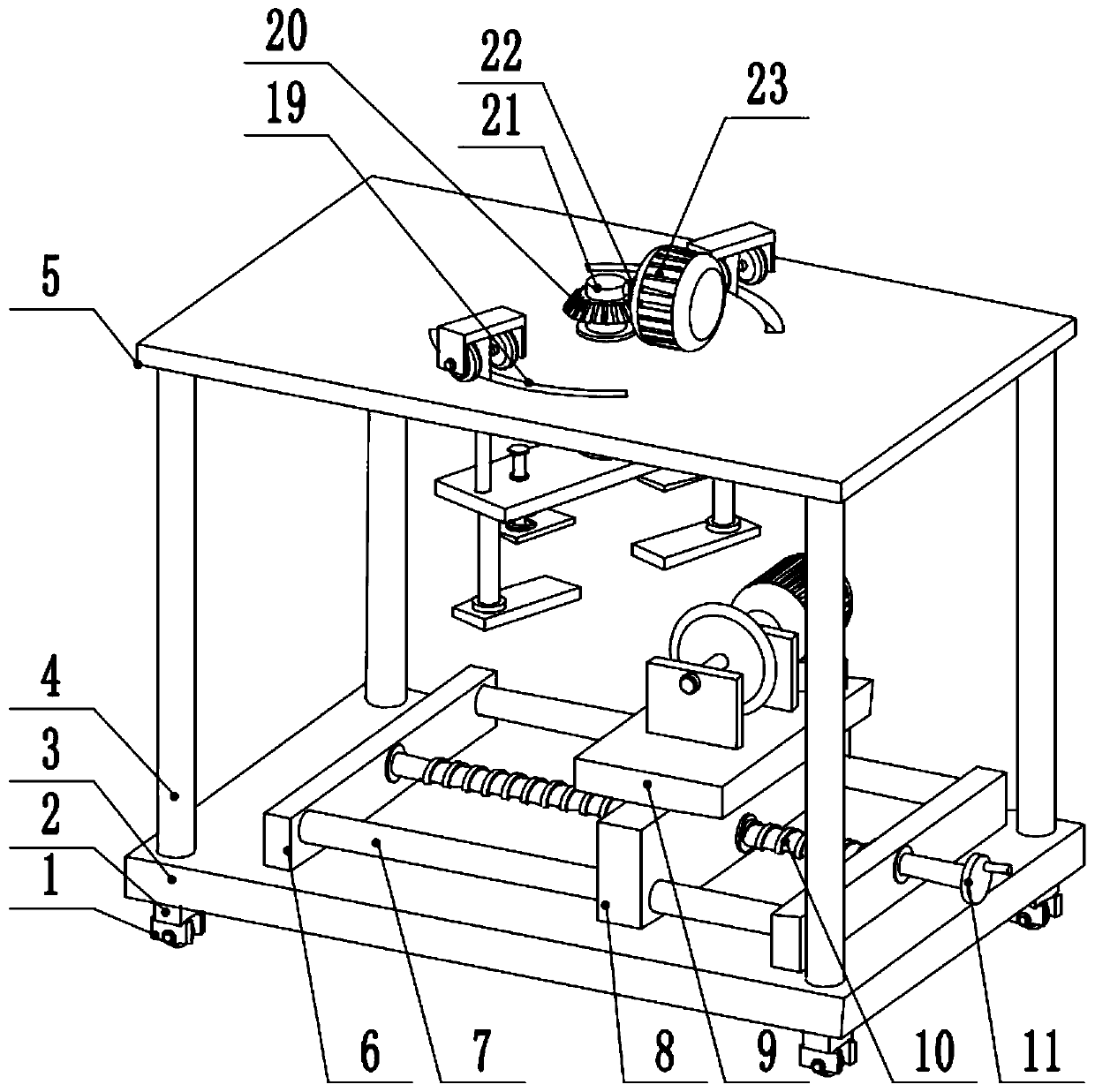

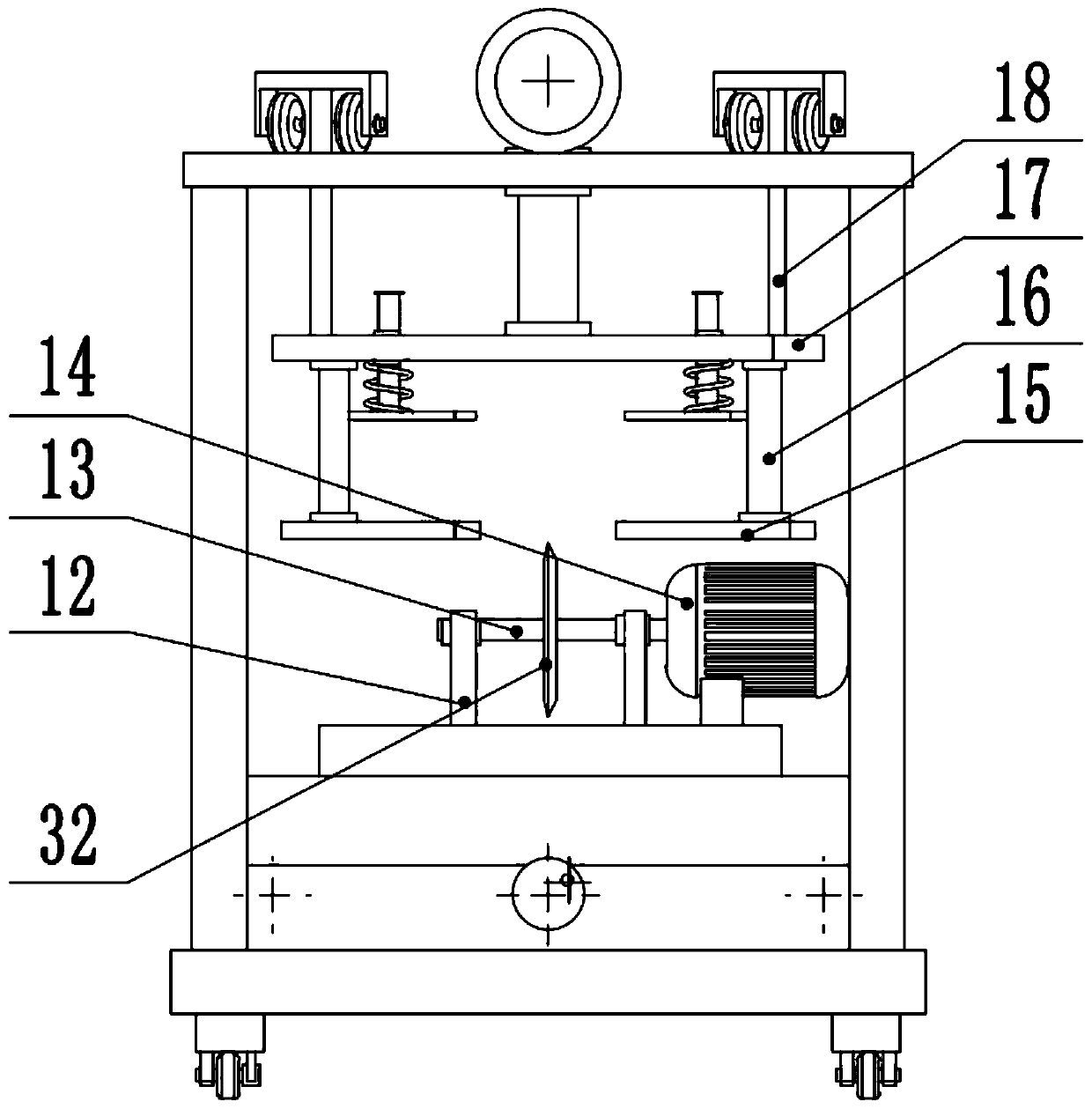

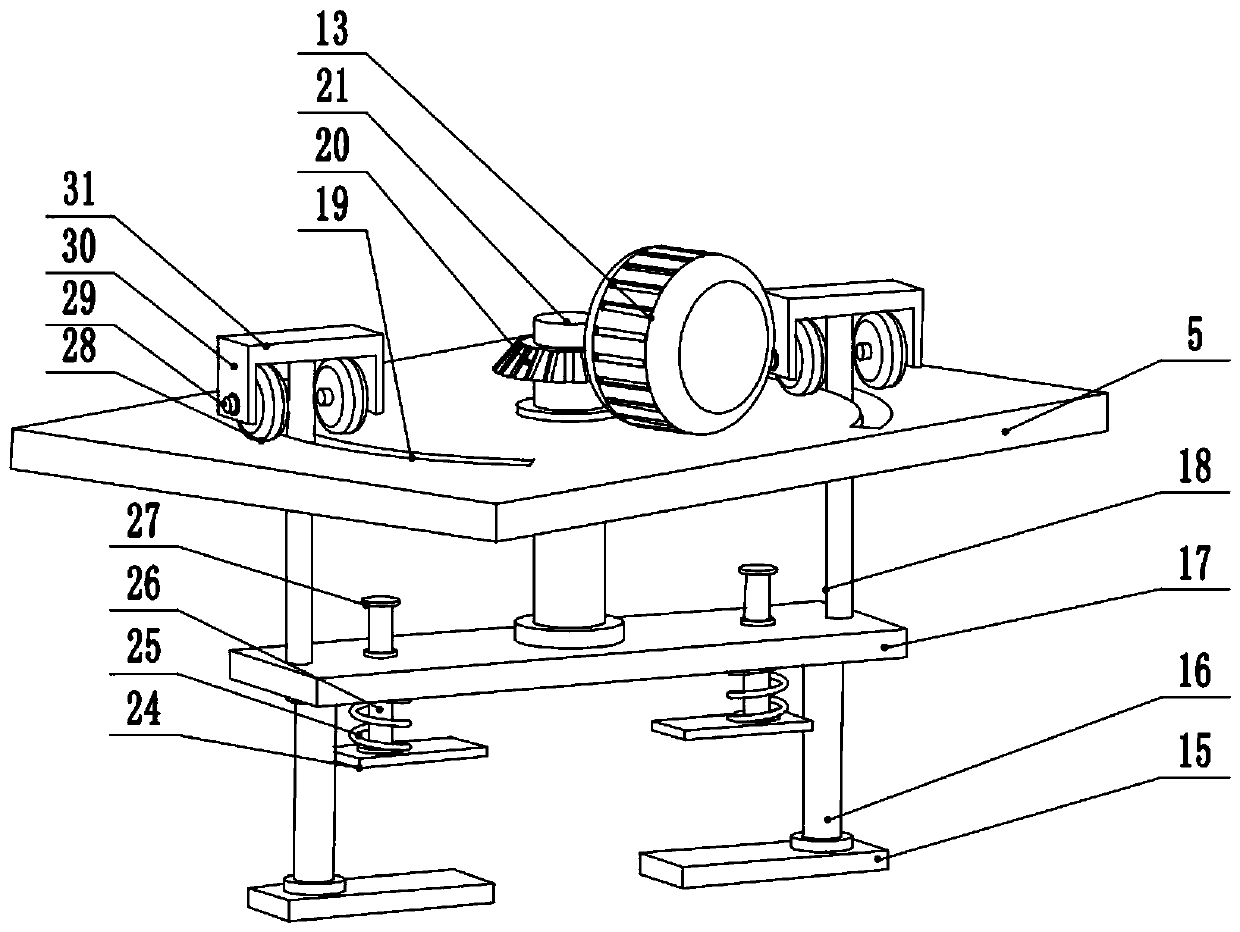

[0025] see Figure 1-3 , a cutting device with high safety for the production of communication equipment shells, comprising a bottom plate 3, spacers 2 are provided on the left and right sides of the lower surface of the bottom plate 3, casters 1 are provided on the lower part of the spacer 2, and the left and right sides of the upper surface of the bottom plate 3 have two sides. The side is provided with a support column 4, and the top of the support column 4 is provided with a top plate 5, and the middle part of the upper surface of the top plate 5 is provided with a second drive motor 23, and the output shaft of the second drive motor 23 is fixedly connected to the first bevel gear 22. A bevel gear 22 meshes with the second bevel gear 20, the second bevel gear 20 is fixedly connected to the upper end of the second main shaft 21, the middle part of the second main shaft 21 is rotatably connected to the middle part of the top plate 5, and the lower end of the second main shaft...

Embodiment 2

[0028] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, except that the upper end of the second support rod 18 is connected to the middle of the lower surface of the third mounting plate 31, and the front and rear sides of the lower surface of the third mounting plate 31 are provided with Side plate 30 is arranged, and the bottom of side plate 30 is rotatably connected with turning bar 29 , and the end of turning bar 29 is provided with supporting wheel 28 . Because the second mounting plate 17 bears the weight of the entire shell and the clamping part, in order to ensure the stability during cutting, a support wheel 28 is set on the upper end of the second support rod 18, and the weight of the clamping device is supported by the support wheel 28. Therefore, the influence of the entire clamping part on the second main shaft 21 is reduced, the strength requirement for the second main shaft 21 is reduced, and the stability of the entire de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com