Ultraviolet surface cleaning machine

A surface cleaning and ultraviolet light technology, which is applied in cleaning methods and appliances, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of reduced illumination and affecting cleaning speed, etc., to achieve enhanced oxidation, improved cleaning efficiency, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

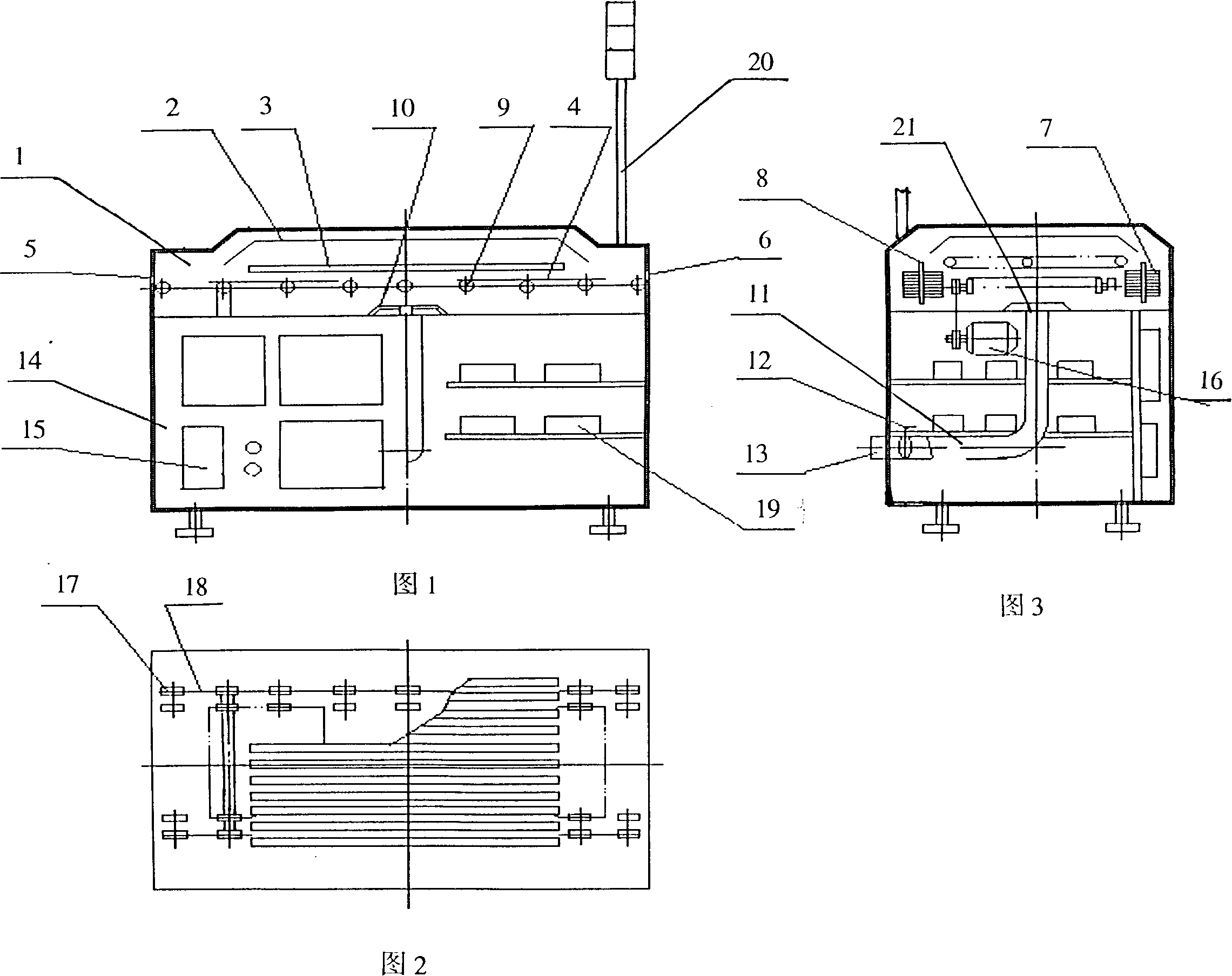

[0019]The ultraviolet surface cleaning machine of the present invention is mainly composed of an ultraviolet light source system, a transmission system, an exhaust system, a safety protection and fault display system, and an electrical control and power supply system. In this embodiment, the whole machine is divided into two parts: the working room 1 and the electrical control and power supply room 14 . As can be seen from Fig. 1, Fig. 2 and Fig. 3, a group of high-intensity ultraviolet light with specific wavelengths of 185nm and 254nm arranged in parallel with the transport direction of the substrate 4 to be cleaned is installed in the working chamber 1 above the substrate 4 to be cleaned. The lamp tube forms an ultraviolet light surface light source 3 with a moderate size. Through scientific calculations, the distance between the light source lamp tubes is preferably 5-10 mm, and the distance between the lamp tubes and the substrate 4 to be cleaned is 10-20 mm, so as to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com