A kind of electronic component diode pin processing method

A technology of electronic components and processing methods, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as low work efficiency, diode extrusion damage, deviation, etc., to improve work efficiency and enhance work The effect of volume and deformation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

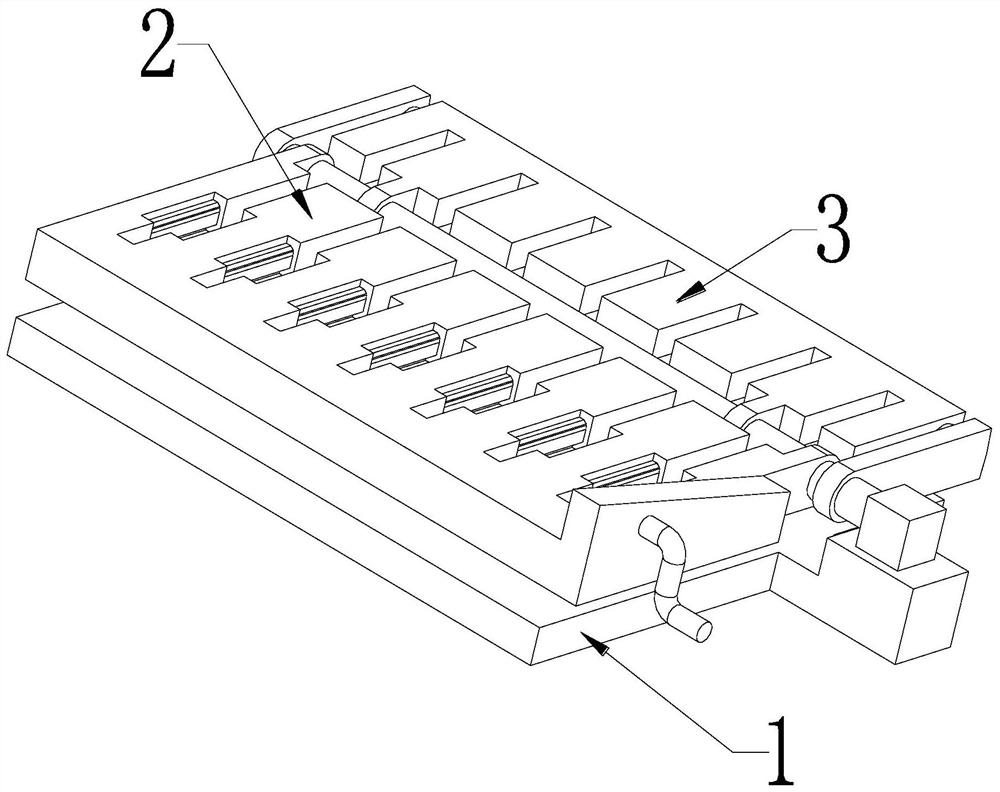

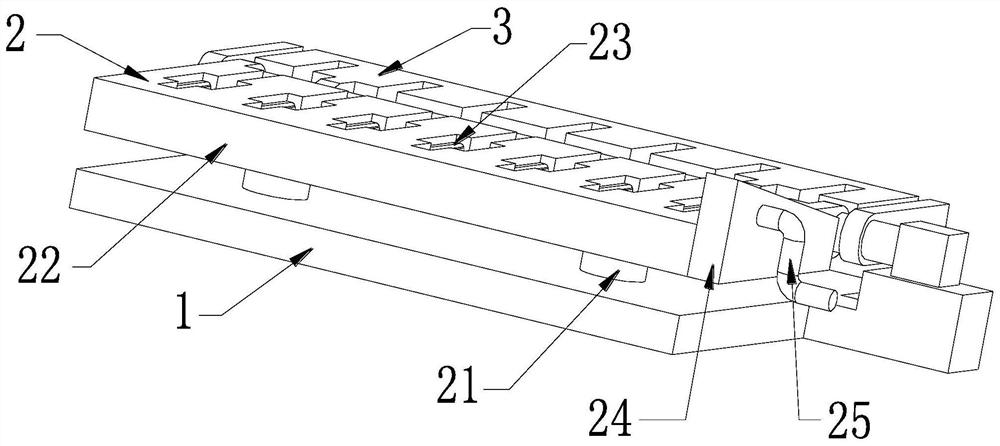

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

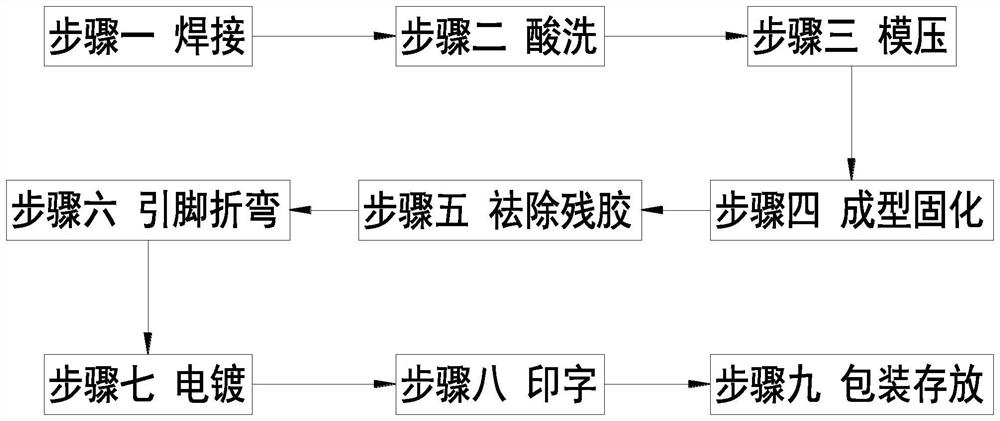

[0036] Such as Figure 1 to Figure 7 As shown, a method for processing diode pins of electronic components mainly includes the following steps:

[0037] Step 1, welding: use the solder piece to pass through a certain temperature to connect the chip to the metal pin;

[0038] Step 2, pickling: put the above-mentioned semi-finished product treated in step 1 into an acidic substance for washing, and chemically corrode the edge surface of the P-N junction of the chip to improve mechanical damage, remove impurities adsorbed on the surface, reduce the surface electric field, and make the P-N junction The breakdown of the junction first occurs from the body to obtain a reverse breakdown voltage close to the theoretical value and a very small surface leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com