Thermosetting plastic ultrasonic molding forming mold-closing device

A molding and mold clamping device technology, which is applied in the field of polymer material molding machinery, can solve the problems of not directly improving disadvantages, device design, and complicated installation, and achieve the effects of easy implementation, energy saving, and simplified design and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

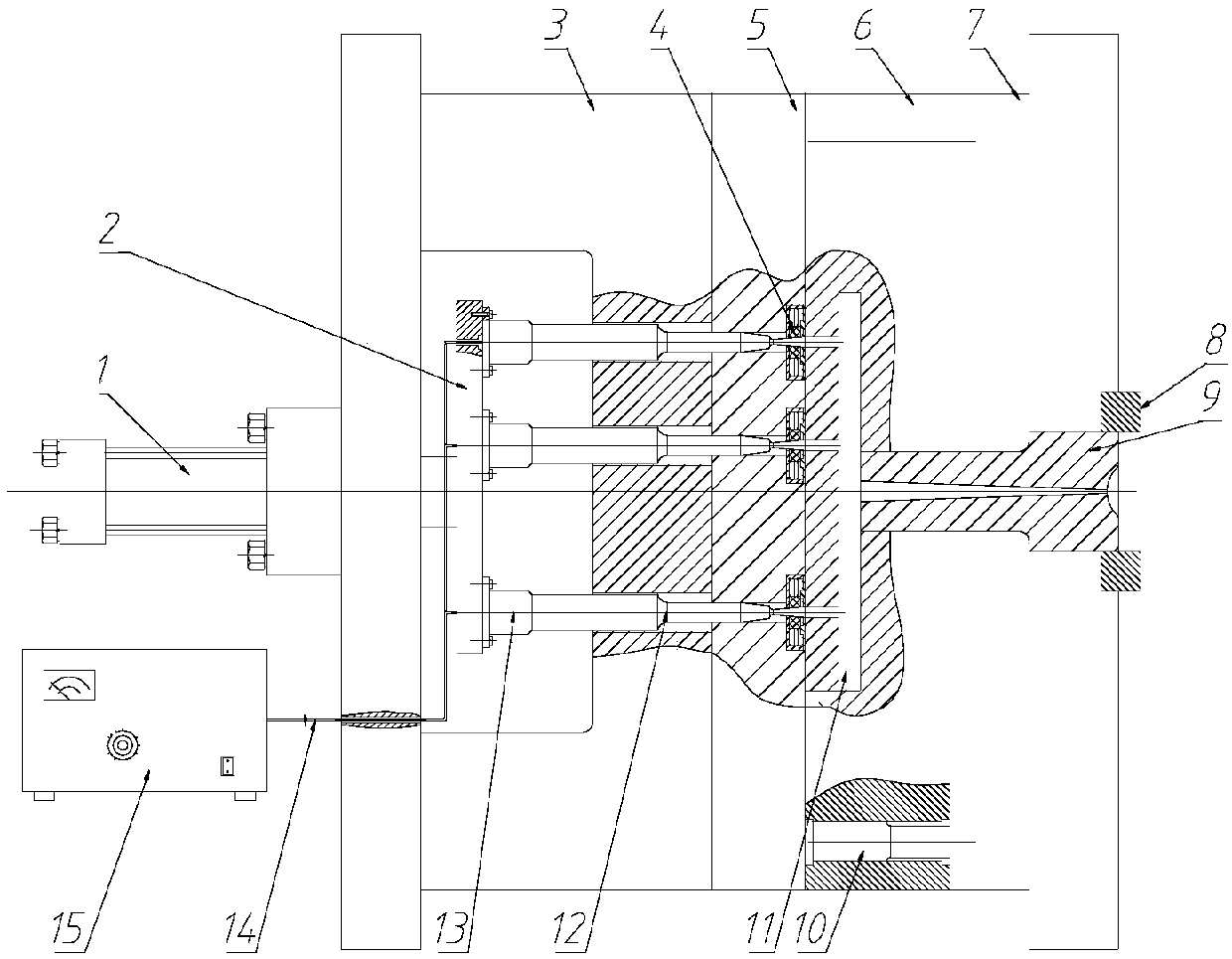

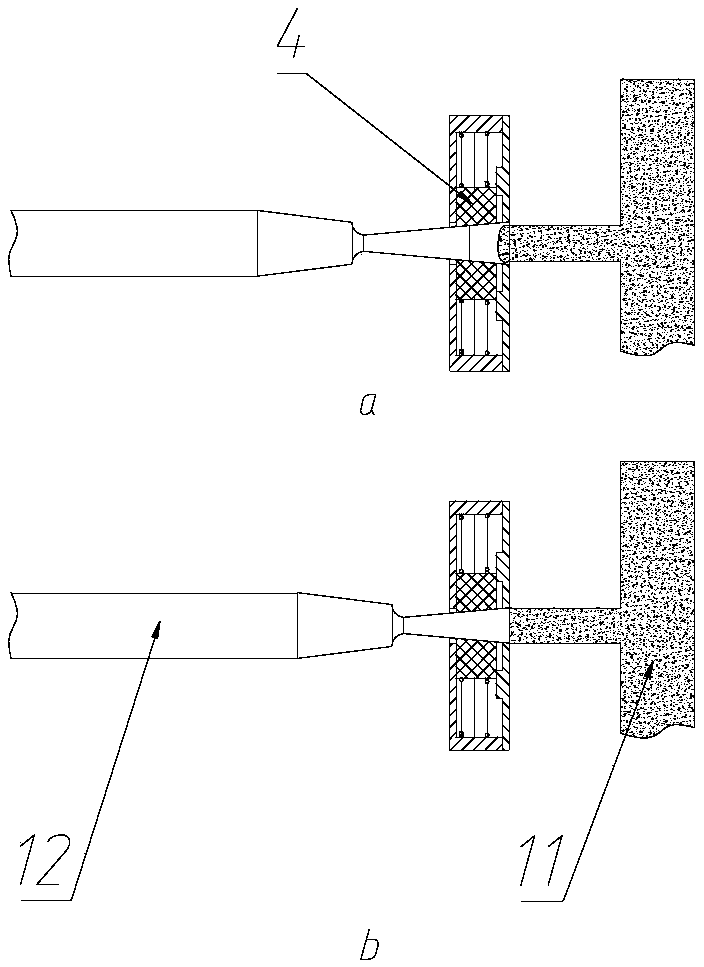

[0024] The present invention is a thermosetting plastic ultrasonic molding mold clamping device ejection mechanism, such as figure 2 As shown; during the work, it needs to work with the movable template 3, the fixed template 7, the complete mold (including the movable mold 5, the fixed mold 6, the guide rod 10, etc.) and the injection accessories (including the positioning ring 7, Main pouring sleeve 8, etc.) and the ejection cylinder 1, ejector plate 2, etc. in the ejector assembly are used together to form a complete mold clamping and ejection system of the injection molding machine, such as figure 1 shown.

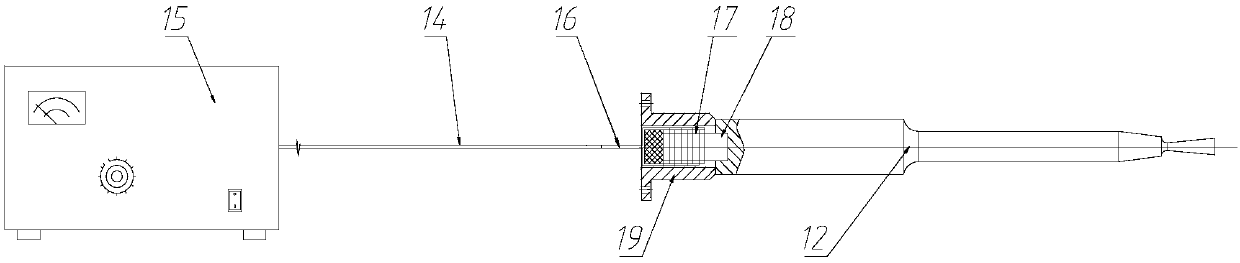

[0025] A thermosetting plastic ultrasonic molding mold clamping device of the present invention also includes: an ultrasonic generator 15, a connecting cable 14, a transducer 13, an amplifying ejector rod 12, etc., wherein the transducer 13 is composed of an electrode wire 16 and an electrode sheet 17 , pre-vibration rod 18 and transducer housing 19 etc. composition. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com