Split type combined spring

A combined spring, split technology, applied in the direction of springs, springs/shock absorbers, spring assemblies composed of several springs, etc., can solve the cracks in rubber parts, consume metal materials and machining time, increase manufacturing costs and production. cycle and other issues, to achieve the effect of shortening the manufacturing and maintenance cycle, eliminating residual internal tensile stress, and simplifying design and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

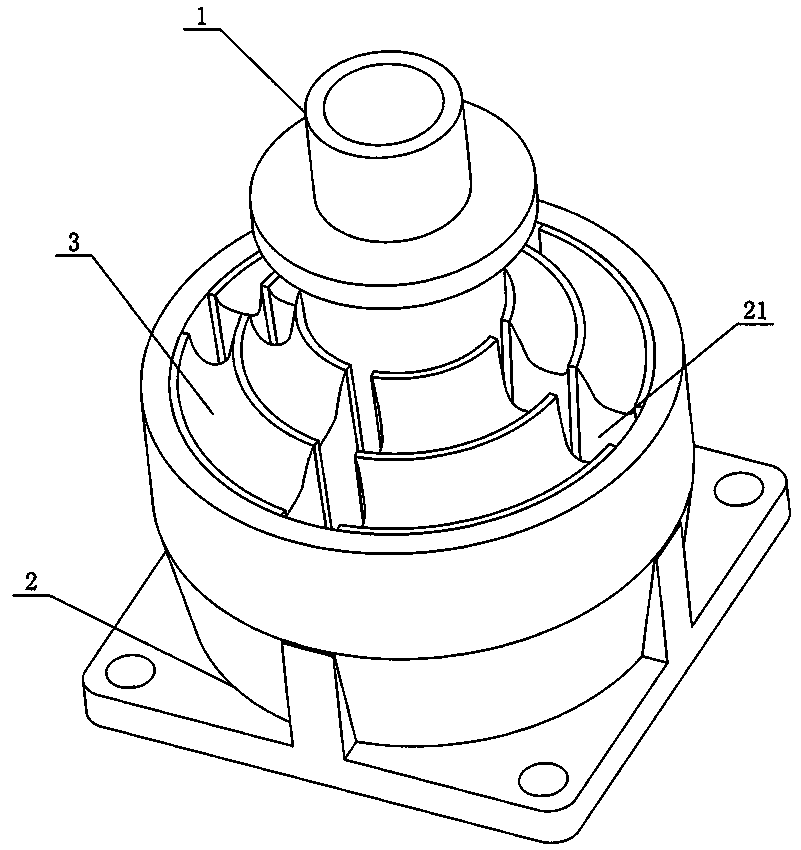

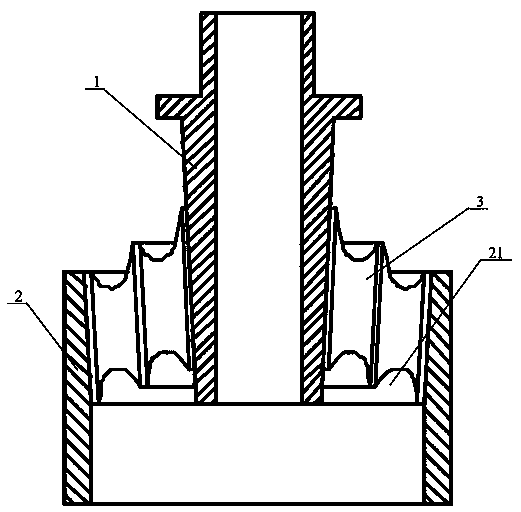

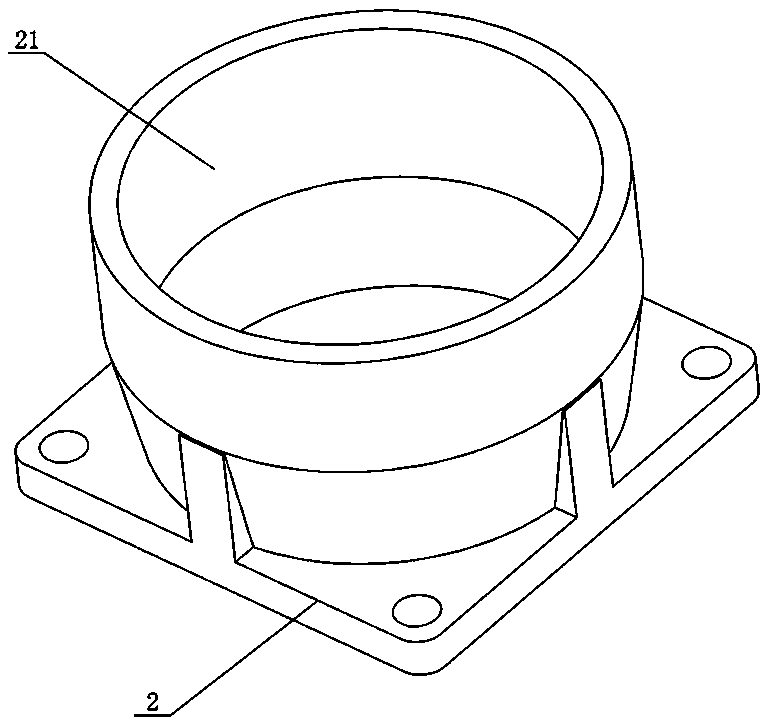

[0030] Figure 1 to Figure 7 Shows the split-type combined spring of this embodiment, including a mandrel 1, a base 2 and nine sections of arc-shaped elastic body 3 for optional installation, figure 1 and Figure 4 The middle part is a four-segment arc-shaped elastic body 3, Figure 6 In the middle are two sections of arc-shaped elastic body 3, Figure 7 The center is a three-arc elastic body 3, and the base 2 is provided with a press-fitting cavity 21. At least two sections of each segment of the arc-shaped elastic body 3 are arranged at intervals along the circumferential direction of the press-fitting cavity 21, and the circumferentially arranged segments The arc-shaped elastic body 3 encloses a force-applying chamber 4 at the central position, and the mandrel 1 passes through the force-applying chamber 4 and presses each segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com