Method for production of electric power steering systems, electric power steering system

A technology of electric power steering and steering system, which is applied in the manufacture of motor generators, electric steering mechanisms, power steering mechanisms, etc., and can solve the problems of expensive and complicated preload adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

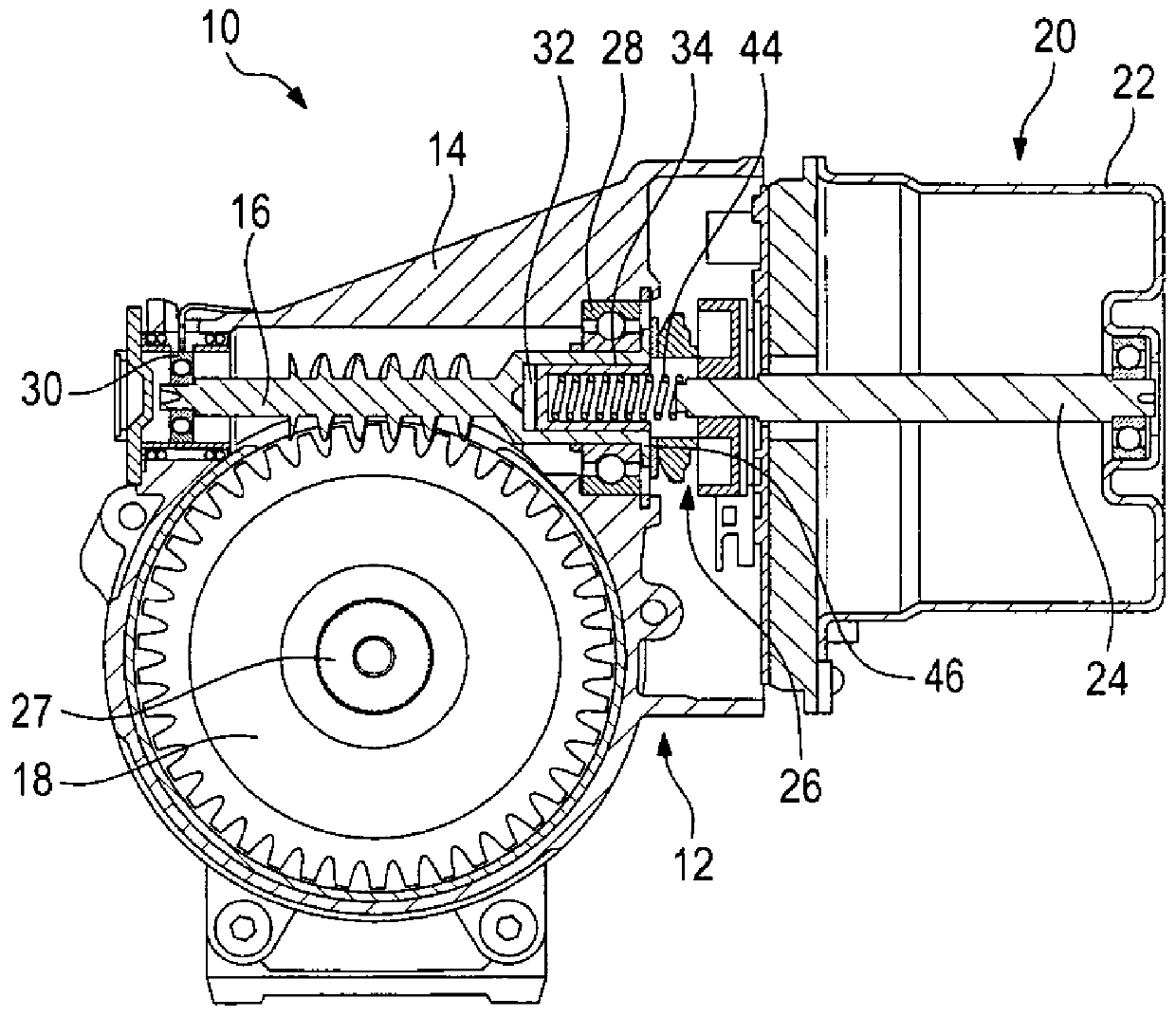

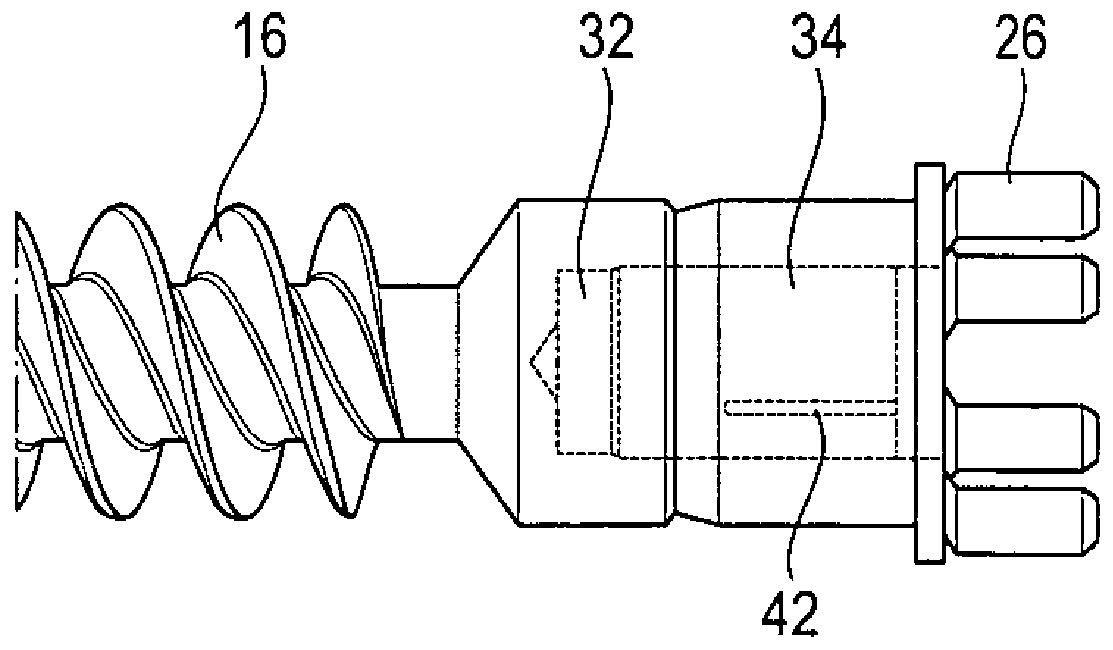

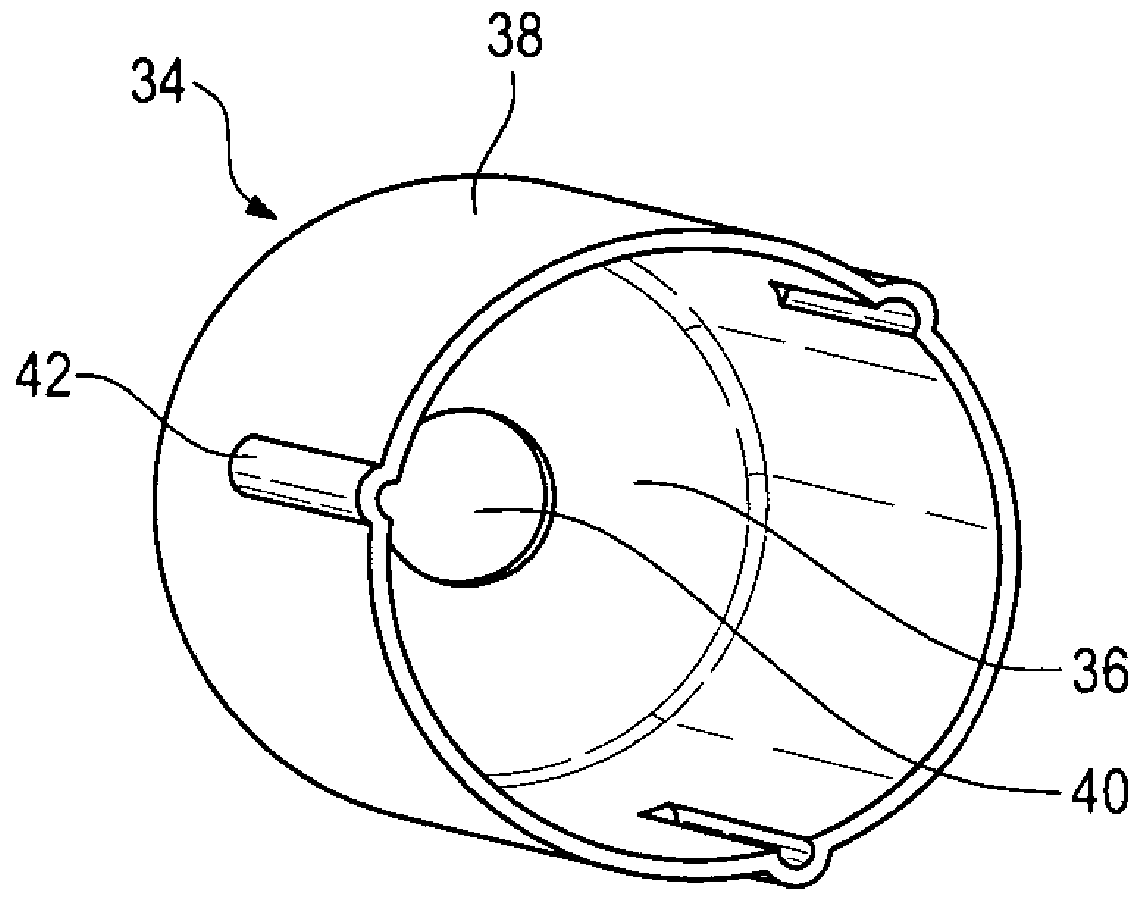

[0031] figure 1 A part of an electric power steering system 10 is schematically shown, which comprises a worm gear 12 with a housing 14 in which a worm shaft 16 and a worm wheel 18 are mounted, the worm shaft 16 and the worm wheel 18 being in meshing.

[0032] Furthermore, the steering system 10 includes an electric motor 20 with a motor housing 22 and a drive shaft 24 which is connected to the worm shaft 16 in a rotationally fixed manner via a coupling device 26 .

[0033] The electric motor 20 is an assist motor of the steering system 10 . The auxiliary force exerted by the electric motor 20 is transmitted via the drive shaft 24 to the coupling 26 , from the coupling to the worm shaft 16 , from the worm shaft to the worm wheel 18 and thus to the steering column 19 .

[0034] exist figure 1 In the illustrated embodiment, the worm gear 18 is connected in a non-rotatable manner to a steering column 27 of the steering system 10 . The steering system 10 is therefore designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com