An activated carbon sewage treatment device and method thereof

A technology of sewage treatment device and sewage treatment method, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems affecting the recovery and reuse of emulsified wastewater, the recovery rate, lubrication There are many oil impurities, which affect the recovery of emulsified waste water, reuse and energy saving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

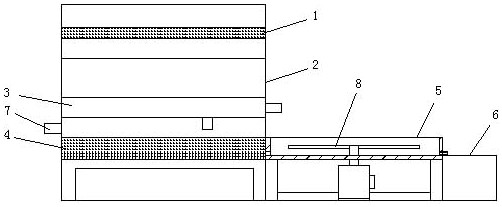

[0028] An activated carbon sewage treatment device, comprising a first grid filter 1, a sludge dewatering machine 2 is arranged at the lower part of the first grid filter 1, an oil-water separator 3 is fixedly arranged at the lower part of the sludge dewatering machine 2, and the oil-water separation The lower part of the boiler 3 is provided with a second grid filter 4, the second grid filter 4 communicates with the sewage treatment tank 5 through a conduit, and the sewage treatment pool 5 communicates with the heating boiler 6 through a conduit. Activated carbon is evenly placed on the grid filter 1 , an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4 , and a stirring mechanism 8 is provided in the sewage treatment tank 5 .

[0029] A treatment method of an activated carbon sewage treatment device, comprising the following steps:

[0030] S1: the waste emulsified wastewater liquid is introduced into the first grid filter 1 for filtration...

Embodiment 2

[0047] An activated carbon sewage treatment device, comprising a first grid filter 1, a sludge dewatering machine 2 is arranged at the lower part of the first grid filter 1, an oil-water separator 3 is fixedly arranged at the lower part of the sludge dewatering machine 2, and the oil-water separation The lower part of the boiler 3 is provided with a second grid filter 4, the second grid filter 4 communicates with the sewage treatment tank 5 through a conduit, and the sewage treatment pool 5 communicates with the heating boiler 6 through a conduit. Activated carbon is evenly placed on the grid filter 1 , an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4 , and a stirring mechanism 8 is provided in the sewage treatment tank 5 .

[0048] A treatment method of an activated carbon sewage treatment device, comprising the following steps:

[0049] S1: the waste emulsified wastewater liquid is introduced into the first grid filter 1 for filtration...

Embodiment 3

[0066] An activated carbon sewage treatment device, comprising a first grid filter 1, a sludge dewatering machine 2 is arranged at the lower part of the first grid filter 1, an oil-water separator 3 is fixedly arranged at the lower part of the sludge dewatering machine 2, and the oil-water separation The lower part of the boiler 3 is provided with a second grid filter 4, the second grid filter 4 communicates with the sewage treatment tank 5 through a conduit, and the sewage treatment pool 5 communicates with the heating boiler 6 through a conduit. Activated carbon is evenly placed on the grid filter 1 , an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4 , and a stirring mechanism 8 is provided in the sewage treatment tank 5 .

[0067] A treatment method of an activated carbon sewage treatment device, comprising the following steps:

[0068] S1: the waste emulsified wastewater liquid is introduced into the first grid filter 1 for filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com