Assembly type ground overhead system with low finished surface height

A prefabricated and ground-based technology, which is applied to local access floors, floors, coverings/linings, etc., can solve the problems of high height of finished surface, large space occupied by ground overhead system, and affecting the sense of indoor space, so as to reduce the finished surface The effect of height and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

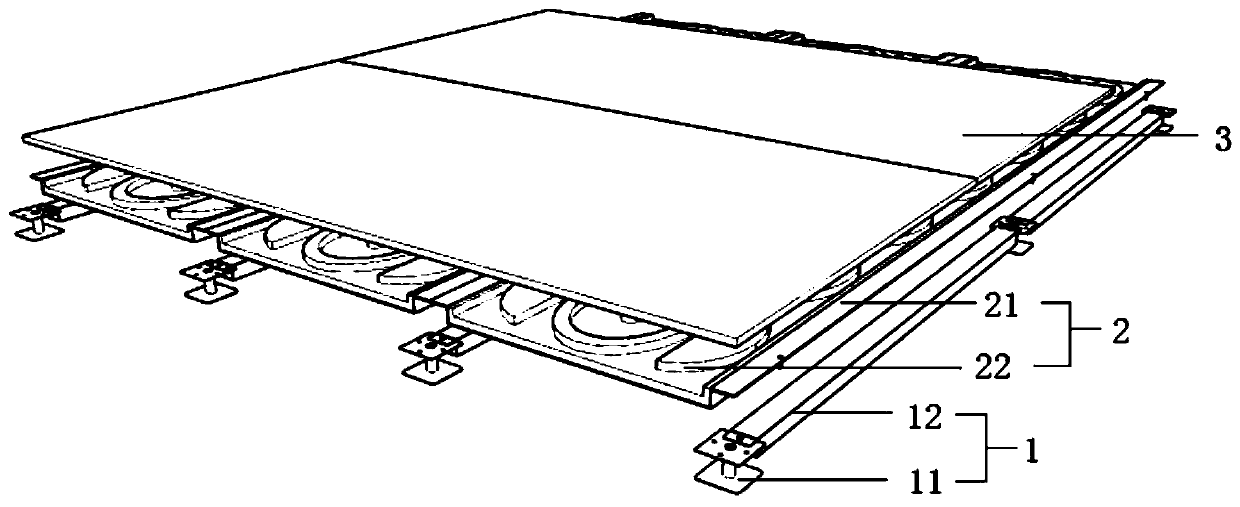

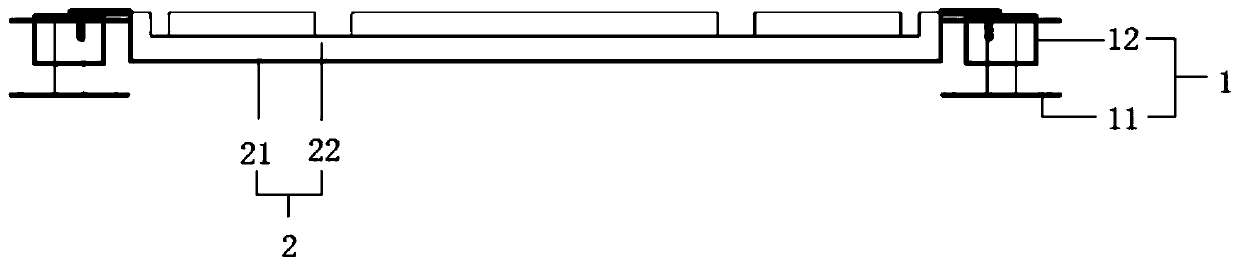

[0034] see Figure 1 to Figure 5 , the figure shows a prefabricated ground overhead system with a low finished surface height provided by Embodiment 1 of the present invention, including:

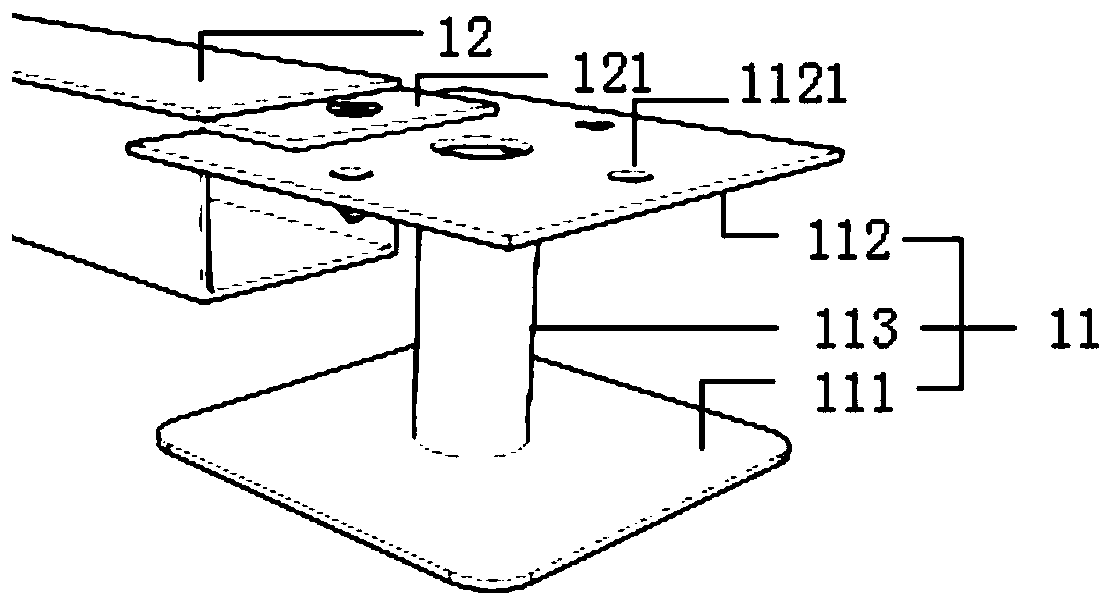

[0035] The support frame module 1 includes a plurality of brackets 11 and a plurality of frames 12. The plurality of brackets 11 are arranged in an array and fixedly installed on the ground. , the connecting portion 121 extending outward, the frame 12 is fixedly installed on the bracket 11 through the connecting portion 121 at both ends;

[0036] The ground module 2, the ground module 2 is fixedly installed on the support frame module 1, the ground module 2 includes a supporting plate 21, the cross section of the supporting plate 21 is U-shaped, and the edges on both sides of the supporting plate 21 are bent outward to form two bending parts 211, the supporting plate 21 is fixedly installed on the support frame module 1 through the bending parts 211 on both sides;

[0037] A balance board...

Embodiment 2

[0052] see Figure 1 to Figure 5 , the figure shows a prefabricated ground overhead system with a low finished surface height provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: roof 112 is a square plate, and the surface of the top plate 112 is provided with four through holes 1121 equidistantly arranged in the circumferential direction, and the four through holes 1121 are located in the center of the four sides of the top plate 112 .

[0053] In the assembled ground overhead system provided by the present invention, the supporting frame module is composed of a plurality of brackets and a plurality of frames. The frames in the frame module are installed on the same straight line or parallel to each other. In order to make the top plate evenly stressed and not easily deformed, four through holes are located in the center of the four sides of the top plate.

Embodiment 3

[0055] see Figure 1 to Figure 5 , the figure shows a prefabricated ground overhead system with a low finished surface height provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: frame 12 and the bent portion 211 are provided with a flexible pad on the surface.

[0056] A layer of flexible cushion is covered on the upper surface of the frame for buffering when the ground module is connected to the frame; a layer of flexible cushion on the surface of the bending part is used for buffering when the ground module is connected to the balance board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com