Temperature sensor tool applied to commodity inspection room and compressor winding temperature calibration method

A temperature sensor and winding temperature technology, which is applied to thermometers, applications of thermometers, and parts of thermometers, etc., can solve the problem of not being able to accurately obtain the local temperature in the compressor cavity of the air conditioner's external unit, and achieve accuracy improvement and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

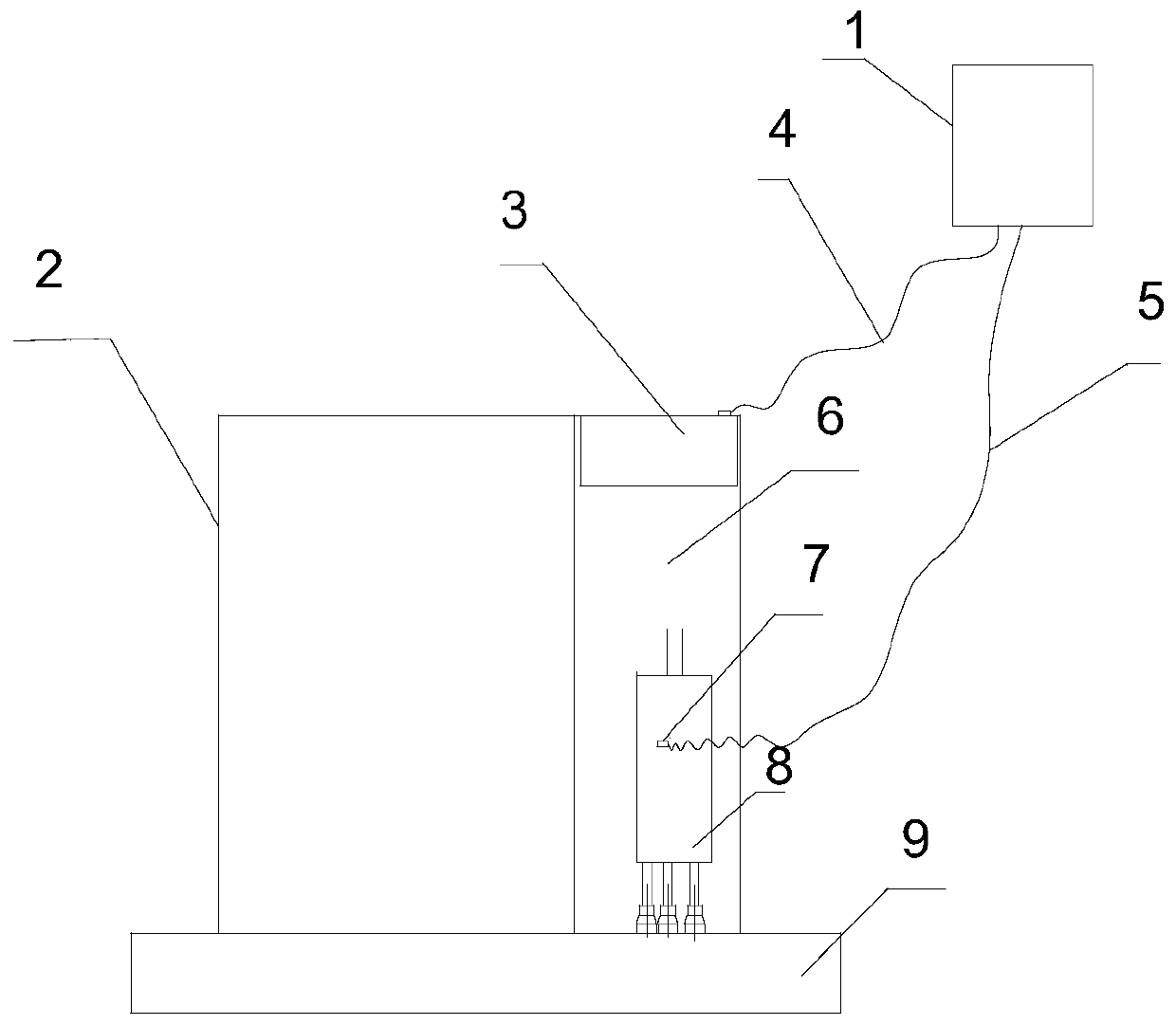

[0030] The temperature sensor tooling applied to the commodity inspection room provided by this embodiment includes: a temperature sensor and a control system, such as figure 1 As shown, the control system 1 is the control system of the commodity inspection room, which performs data interaction with the electronic control component 3 of the air conditioner external unit 2 to be tested through the data transmission line 4, and collects and obtains relevant parameters of the air conditioner external unit 2 (such as: voltage, current, working Frequency, etc.) are used for performance testing. In order to detect the local temperature in the compressor cavity 6 of the air conditioner outdoor unit 2 to be tested on the production line conveyor belt 9 in the commodity inspection room, the staff can manually place the probe 7 of the temperature sensor in the compression In the vicinity of the compressor body 8 in the machine cavity 6, the temperature sensing signal of the probe 7 is tr...

Embodiment 2

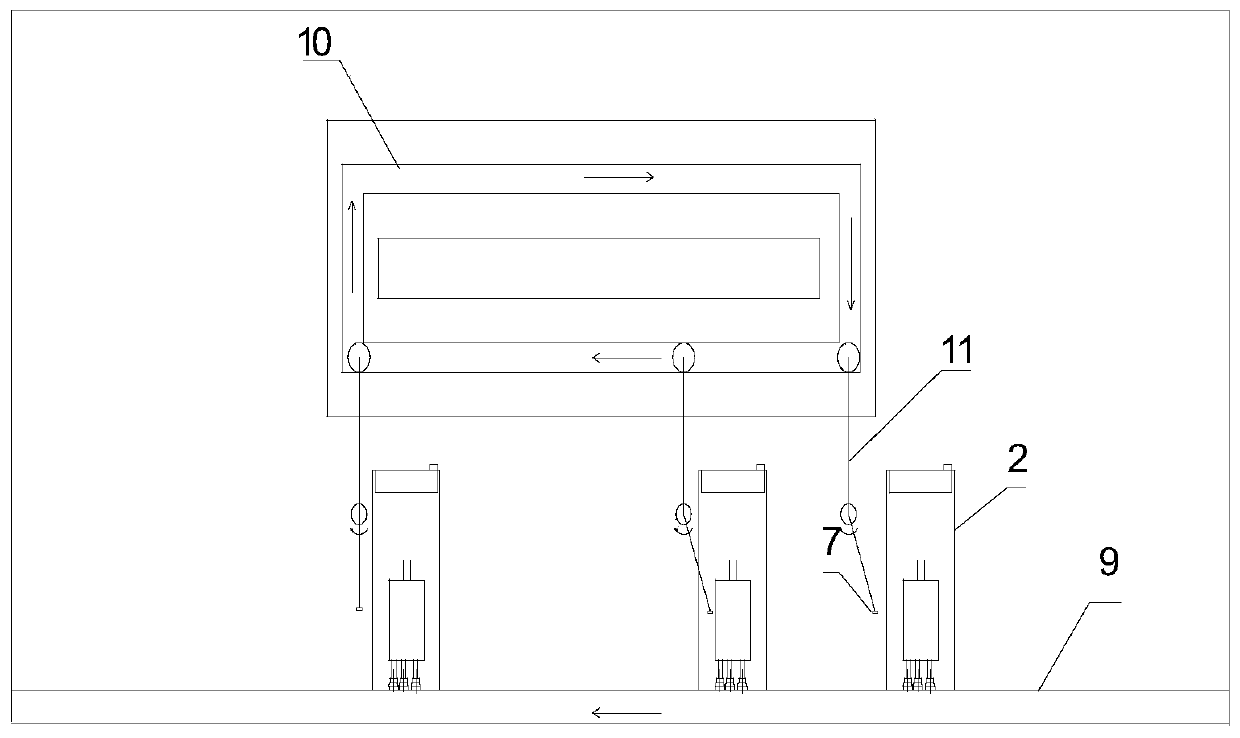

[0032] Compared with Embodiment 1, in order to realize automatic detection of local temperature in the compressor cavity, improve detection efficiency, and save labor costs, the temperature sensor tooling in this embodiment also adds a position adjustment mechanism, and the temperature sensor is set on the position adjustment mechanism Above, when the air conditioner outdoor unit to be tested on the production line conveyor belt in the commodity inspection room reaches the corresponding position, the position adjustment mechanism operates, and the temperature sensor is placed in the compressor cavity of the air conditioner to be tested, and the local temperature in the compressor cavity is collected.

[0033] As a means of implementation, such as figure 2 As shown, the position adjustment mechanism can include a loop-shaped transmission device 10 and a mechanical arm 11, and the mechanical arm 11 is fixed on the conveyor belt of the loop-shaped transmission device 10, and can ...

Embodiment 3

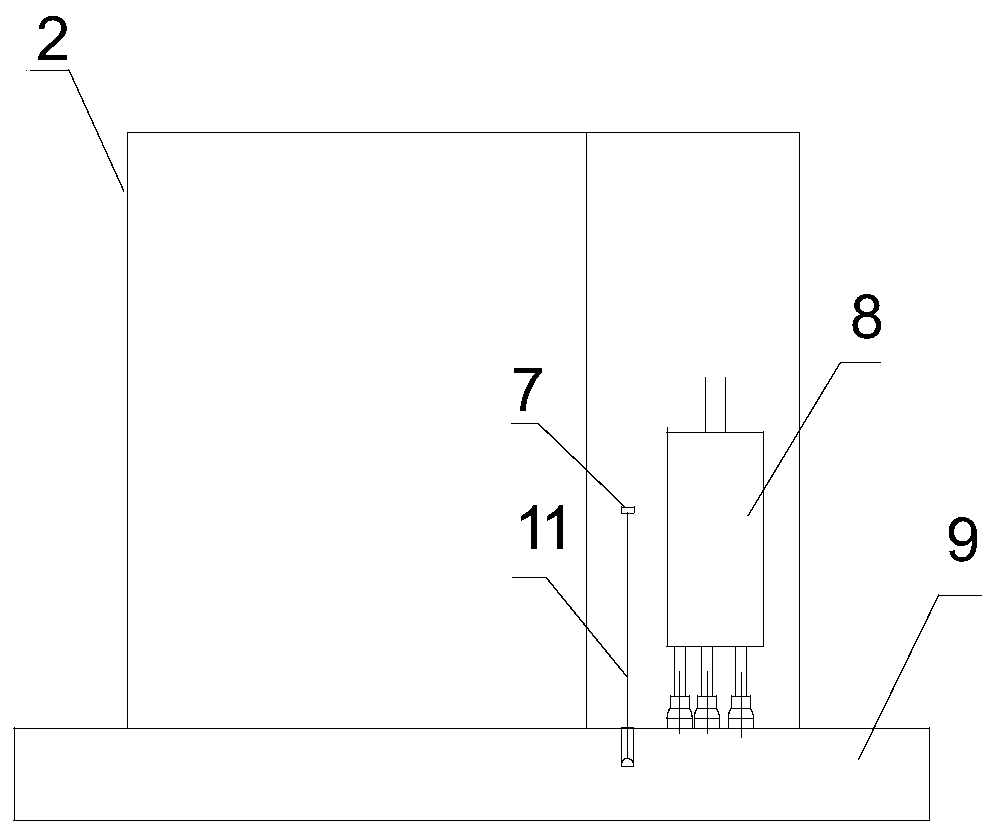

[0037] This embodiment is also a scheme of using a position adjustment mechanism for automatic temperature collection. The difference from Embodiment 2 is that this embodiment does not need to set a return transmission device, but directly arranges the position adjustment mechanism on the production line conveyor belt 9. Can move together with the production line conveyor belt 9, such as image 3 shown. When the position adjustment mechanism detects that the air conditioner external unit 2 to be tested passes by in front, it extends the mechanical arm 11, so that the probe 7 on the mechanical arm 11 is close to the compressor body 8 of the air conditioner external unit 2 to be tested, so as to detect the temperature in the cavity , retract the mechanical arm 11 after the temperature detection is finished.

[0038] For the control system of the commodity inspection room, after obtaining the local temperature data in the compressor cavity detected by the tooling, this temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com