Resin composition for printed wiring board, copper foil with resin, copper clad laminate, and printed wiring board

A technology of resin composition and printed circuit board, which is applied to printed circuit components, circuit substrate materials, etc., and can solve problems such as poor dielectric properties, high dielectric loss tangent, and unsuitability for high frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

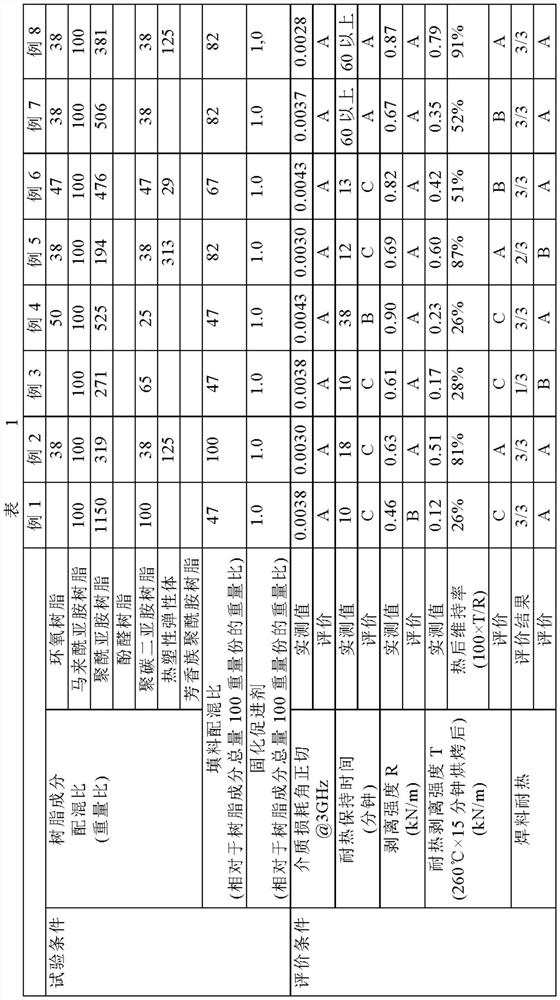

[0053] The present invention is further specifically described based on the following examples.

example 1~18

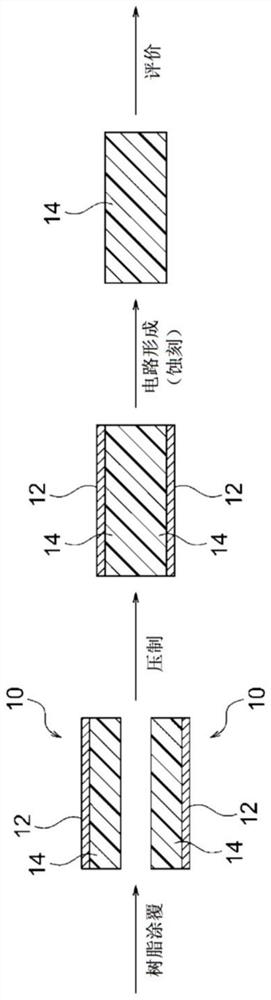

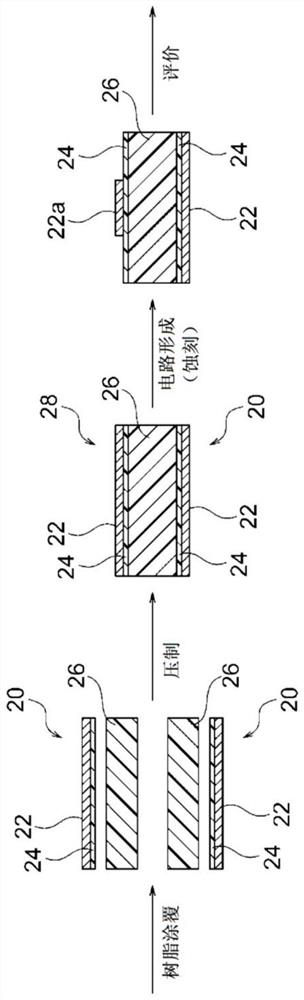

[0055] A resin varnish containing a resin composition was prepared, and a resin-attached copper foil was produced and evaluated using the resin varnish. Specifically, as follows.

[0056] (1) Preparation of resin varnish

[0057] First, as raw material components for resin varnishes, the following resin components, imidazole-based hardening accelerators, and inorganic fillers were prepared.

[0058] -Epoxy resin: Nippon Kayaku Co., Ltd., NC-3000H (biphenylaralkyl type, epoxy equivalent 288g / Eq)

[0059] -Maleimide resin: manufactured by Nippon Kayaku Co., Ltd., MIR-3000 (biphenyl aralkyl type, functional group equivalent 275 g / Eq)

[0060] -Polyimide resin: manufactured by Arakawa Chemical Industry Co., Ltd., PIAD-301 (terminal functional group: carboxyl group; solvent: mixed solution of cyclohexanone, methylcyclohexane, and ethylene glycol dimethyl ether; dielectric constant ( 1GHz): 2.70; dielectric loss tangent (1GHz): 0.003; softening point: 140°C)

[0061] -Phenolic r...

example 19

[0119] Example 19 (Compare)

[0120] Use 260 parts by weight of phenolic resin (Meiwa Chemicals Co., Ltd., MEH-7500) instead of maleimide resin, polyimide resin, polycarbodiimide resin and thermoplastic elastomer, and make the epoxy resin 100 parts by weight. The preparation and various evaluations of the resin varnish were performed in the same manner as in Example 9 except for the parts by weight. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap