A Composite Printing Process for Printed Sofa Fabrics

A printing process, printing sand technology, applied in lamination auxiliary operations, chemical instruments and methods, household appliances, etc., can solve the problems of poor cloth transfer effect, inability to adapt to cloth, poor flexibility, etc., to increase fluidity and reduce The effect of glue dosage and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

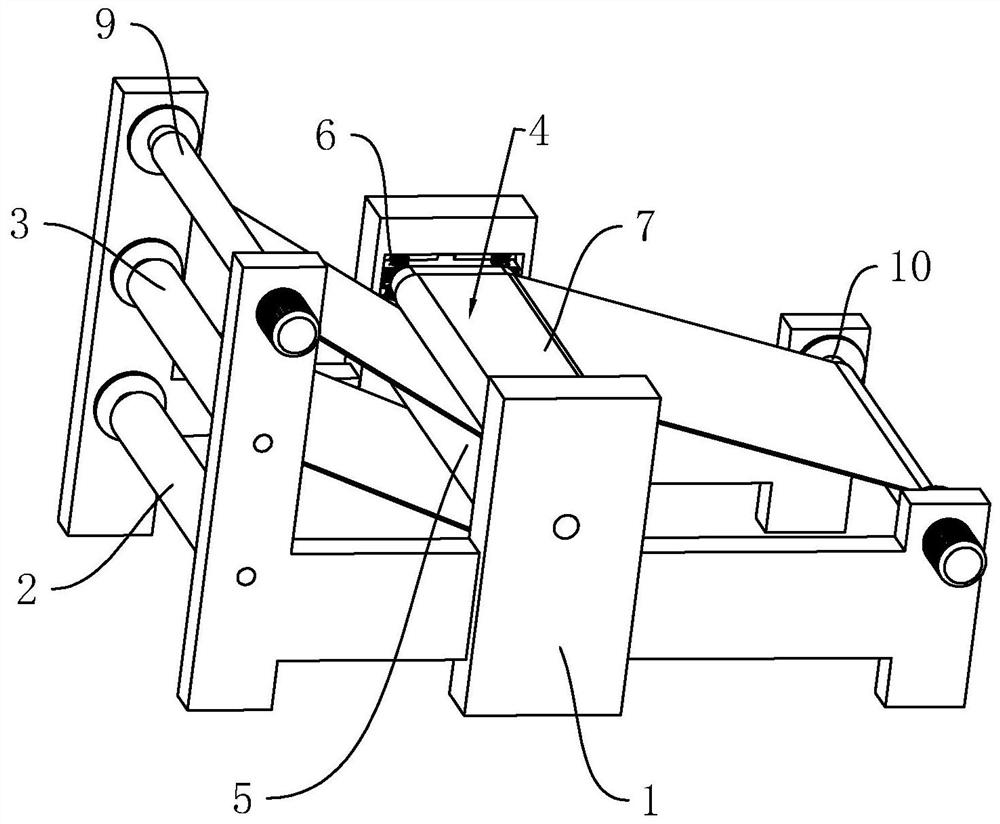

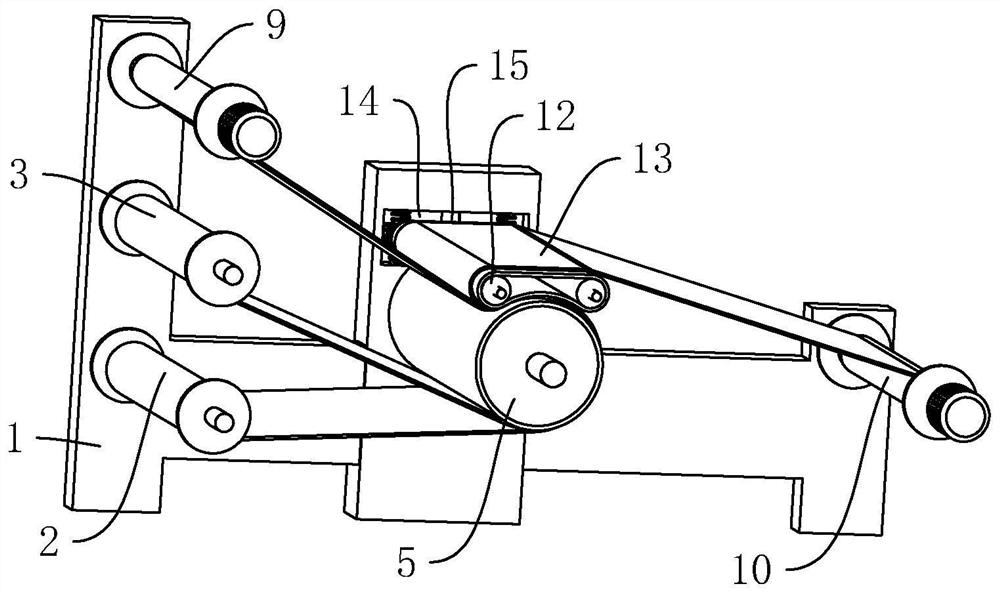

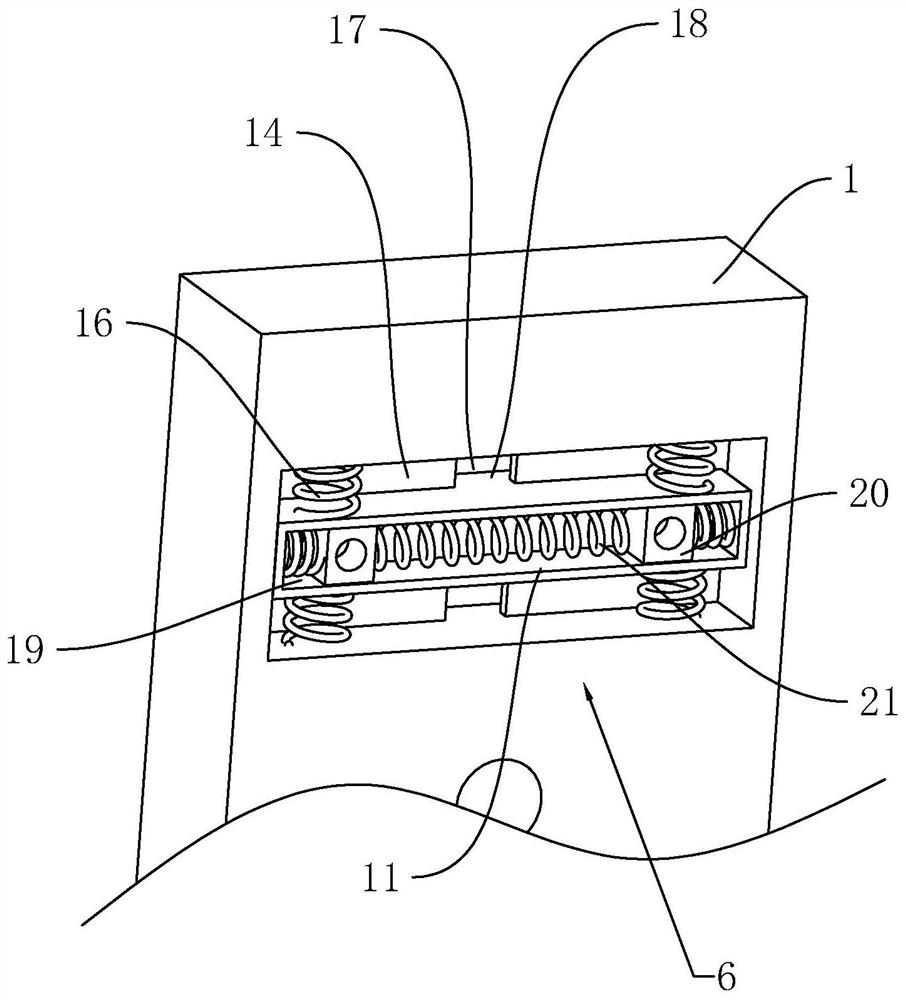

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] refer to figure 1 and Figure 5 , which is a compound printing process for printed sofa cloth disclosed in the present invention, comprising the following steps, step S1: cutting the gray cloth, selecting the cloth that needs to be compounded, and trimming the edges of the gray cloth by a cutting machine to form a base cloth; Step S2: Apply glue to the base cloth, apply glue on the surface of the base cloth through a glue applicator; Step S3: Compound, compound a layer of surface cloth on the surface of the base cloth coated with glue through a compound machine to form a composite cloth; Step S4: Compound Cloth surface treatment, the surface of the composite cloth to be printed is preliminarily leveled by a leveling device; step S5: transfer printing, printing is performed on the surface of the composite cloth by a transfer printing device. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com