Revolution and autorotation pot evaporation deposition structure adopting 3D evaporation deposition

A technology of revolution and evaporation, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of poor step coverage, inconsistent coating structure, unable to provide linear operation, etc., to achieve stable structural support , The effect of better coating thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

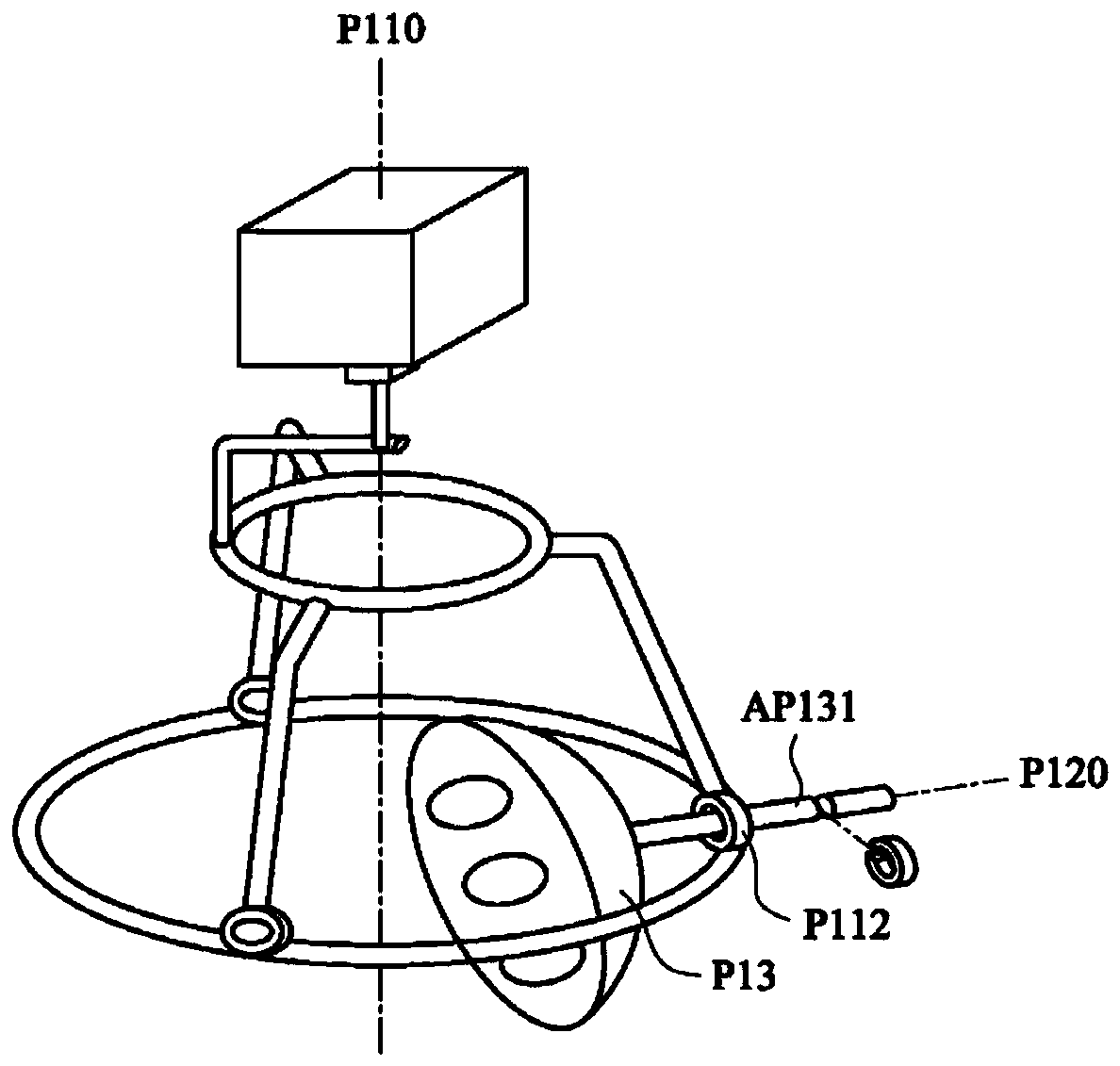

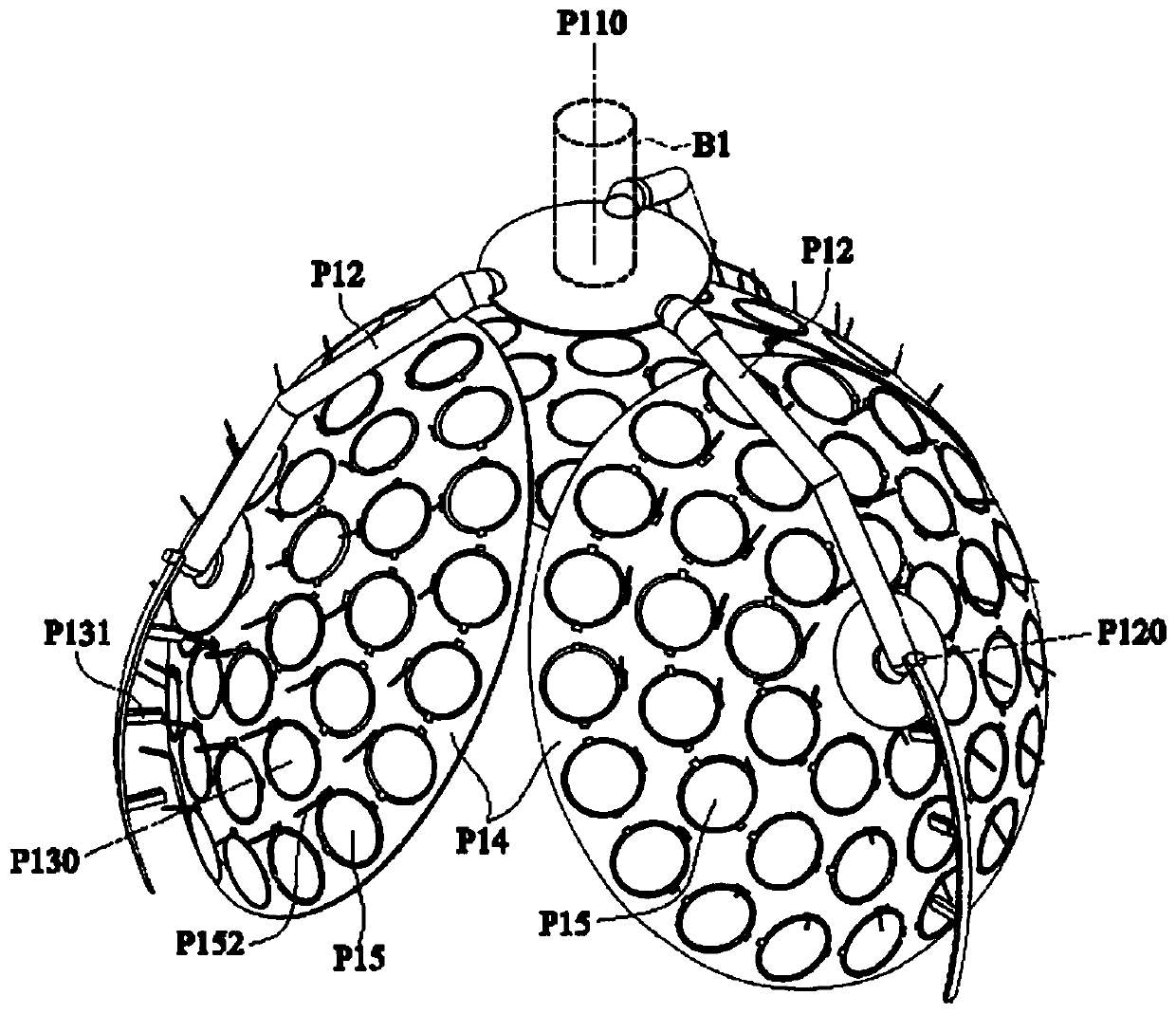

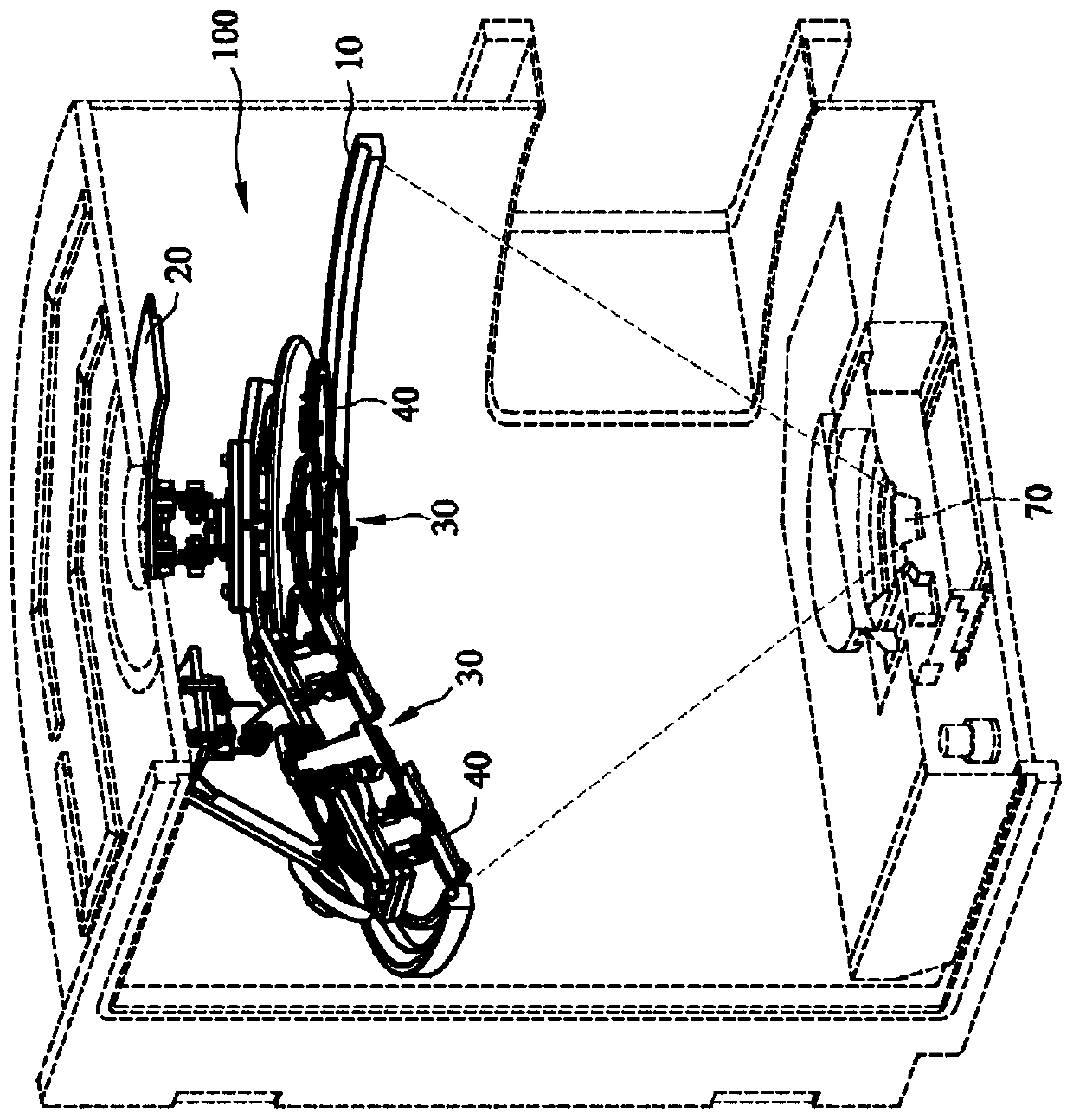

[0058] like Figure 2 to Figure 4 As shown, the present embodiment is a male-rotating coating pot structure 100 for 3D evaporation, which includes: a revolving bottom plate 10 ; a revolving top plate 20 ; a plurality of coating pot rotation modules 30 ; and a plurality of wafer carriers 40 .

[0059] The revolving base 10 is used as the bottom support of the entire revolving coating pot structure 100 , and in order to achieve the effect of rotation, the revolving base 10 can be a circular orbit.

[0060] The revolving top plate 20 has a plurality of supports 210 so that the revolving top plate 20 can be erected on the revolving chassis 10 . In order to make the revolving top plate 20 rotate effectively, a revolving wheel 220 can be provided at the bottom of each supporting member 210 . The revolving top plate 20 can smoothly run around the revolving chassis 10 by means of the revolving runner 220 .

[0061]In order to allow the revolving top plate 20 to be arranged on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com