Production process of digital printing towel

A production process and digital printing technology, which is applied in the processing of textile materials, continuous processing of textile materials, and weaving, etc., can solve the problems of inability to meet industrialized production, complex preparation process, etc., and achieve easy mass production and simple production process. , bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

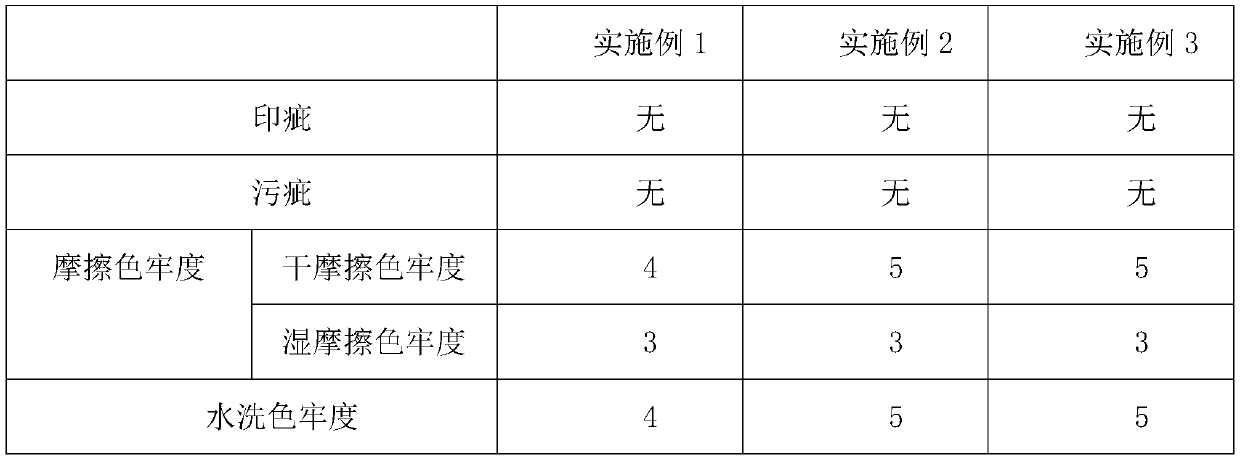

Embodiment 1

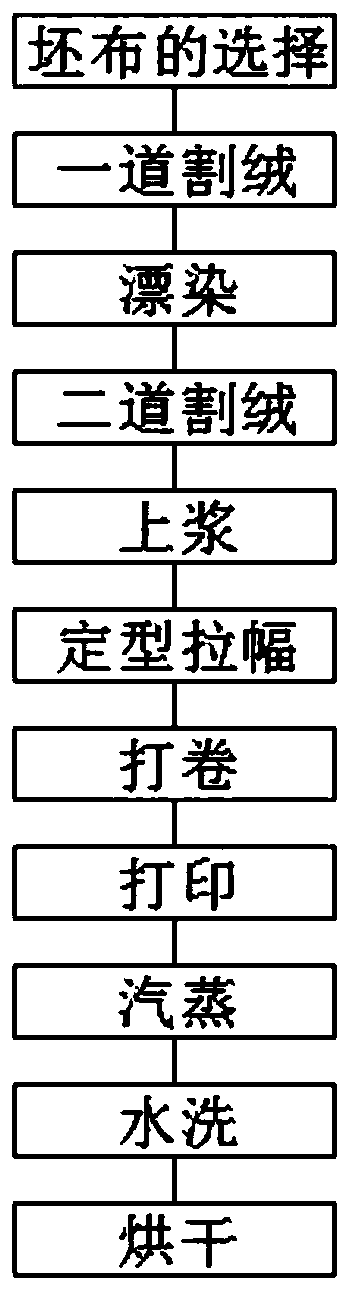

[0028] A production process of digitally printed towels, through the steps of gray fabric selection, velvet cutting, bleaching and dyeing, velvet cutting, sizing, tenter setting, rolling, printing, steaming, washing and drying, to complete the production of digitally printed towels Production process; concrete steps are as follows:

[0029] (1) Selection of gray cloth: choose towel gray cloth with a warp density of 114 threads / 10cm and a weft density of 180 threads / 10cm as a raw material.

[0030] (2) One cut velvet: cut velvet three times along the wool, against the wool and along the wool.

[0031] (3) Bleaching and dyeing: the gray cloth after the above-mentioned cut velvet is subjected to a deboiling process, then bleached in a bleaching solution, and then pickled, and the pickled towel cloth is pre-dried.

[0032] The descaling process is as follows: put the gray cloth after velvet cutting into hot water at 85 degrees Celsius for desizing and scouring, and add 3 g / L of 1...

Embodiment 2

[0044] A production process of digitally printed towels, through the steps of gray fabric selection, velvet cutting, bleaching and dyeing, velvet cutting, sizing, tenter setting, rolling, printing, steaming, washing and drying, to complete the production of digitally printed towels Production process; concrete steps are as follows:

[0045] (1) Selection of gray cloth: choose towel gray cloth with a warp density of 120 threads / 10cm and a weft density of 200 threads / 10cm as a raw material.

[0046] (2) One cut velvet: cut velvet three times along the wool, against the wool and along the wool.

[0047] (3) Bleaching and dyeing: the gray cloth after the above-mentioned cut velvet is subjected to a deboiling process, then bleached in a bleaching solution, and then pickled, and the pickled towel cloth is pre-dried.

[0048] The descaling process is as follows: put the gray cloth after velvet cutting into hot water at 95 degrees Celsius for desizing and scouring, and add 5 g / L of 1...

Embodiment 3

[0060] A production process of digitally printed towels, through the steps of gray fabric selection, velvet cutting, bleaching and dyeing, velvet cutting, sizing, tenter setting, rolling, printing, steaming, washing and drying, to complete the production of digitally printed towels Production process; concrete steps are as follows:

[0061] (1) Selection of gray cloth: choose towel gray cloth with a warp density of 117 threads / 10cm and a weft density of 190 threads / 10cm as the raw material.

[0062] (2) One cut velvet: cut velvet three times along the wool, against the wool and along the wool.

[0063] (3) Bleaching and dyeing: the gray cloth after the above-mentioned cut velvet is subjected to a deboiling process, then bleached in a bleaching solution, and then pickled, and the pickled towel cloth is pre-dried.

[0064] The descaling process is as follows: put the gray cloth after velvet cutting into hot water at 90 degrees Celsius for desizing and scouring, and add 4 g / L of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com