Rock mass real-time wave velocity measurement and quality evaluation method

A quality evaluation and rock mass technology, applied in measuring devices, measuring propagation velocity, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of random intermixing and complex evolution of microstructure, and achieve low price, simple operation and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The steps of a method for rock mass real-time wave velocity measurement and quality evaluation are as follows:

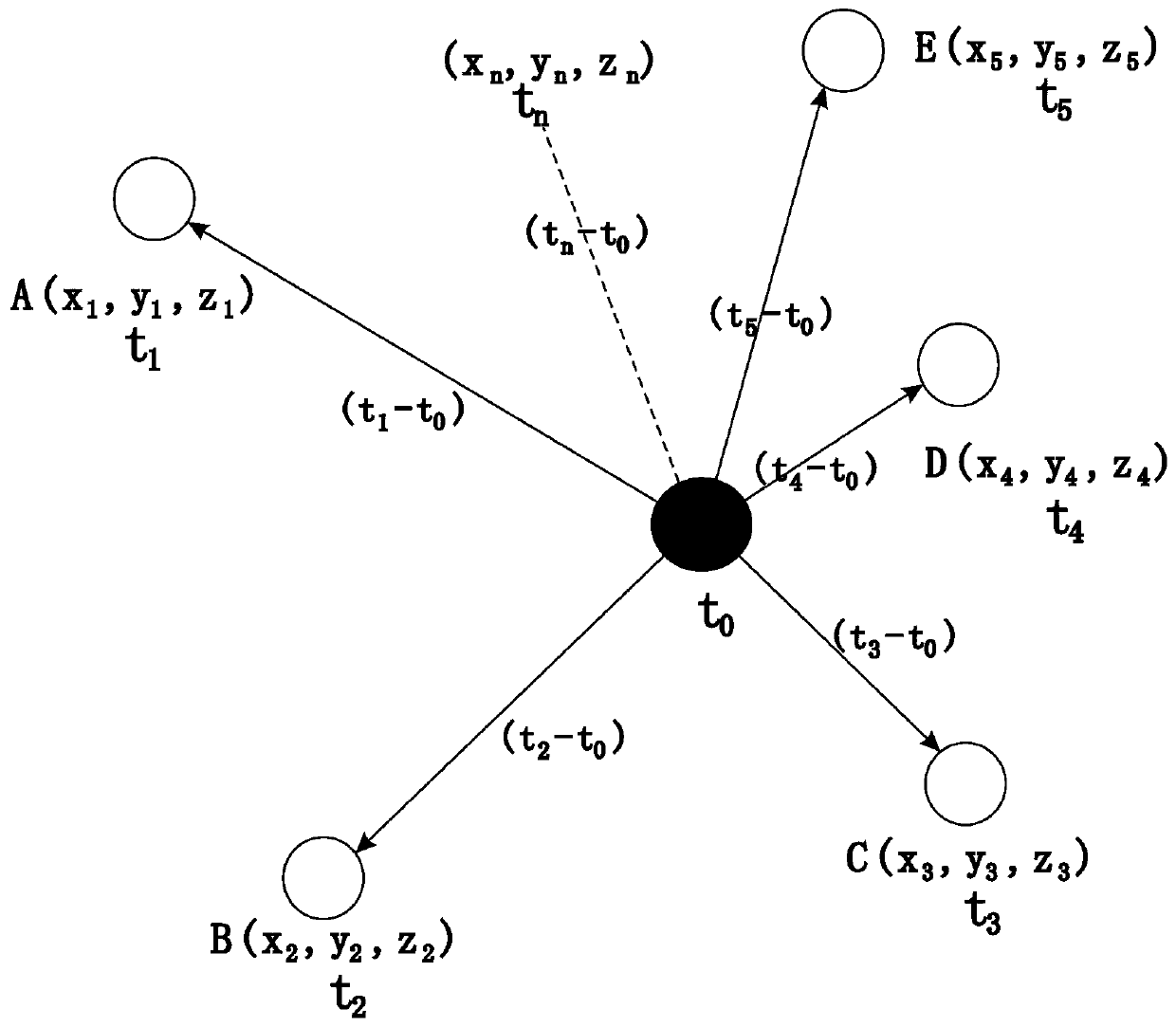

[0068] (1) First determine the coordinates of each sensor, A(x 1 ,y 1 ,z 1 ), B, (x 2 ,y 2 ,z 2 )C(x 3 ,y 3 ,z 3 ), D(x 4 ,y 4 ,z 4 ), E(x 5 ,y 5 ,z 5 )...

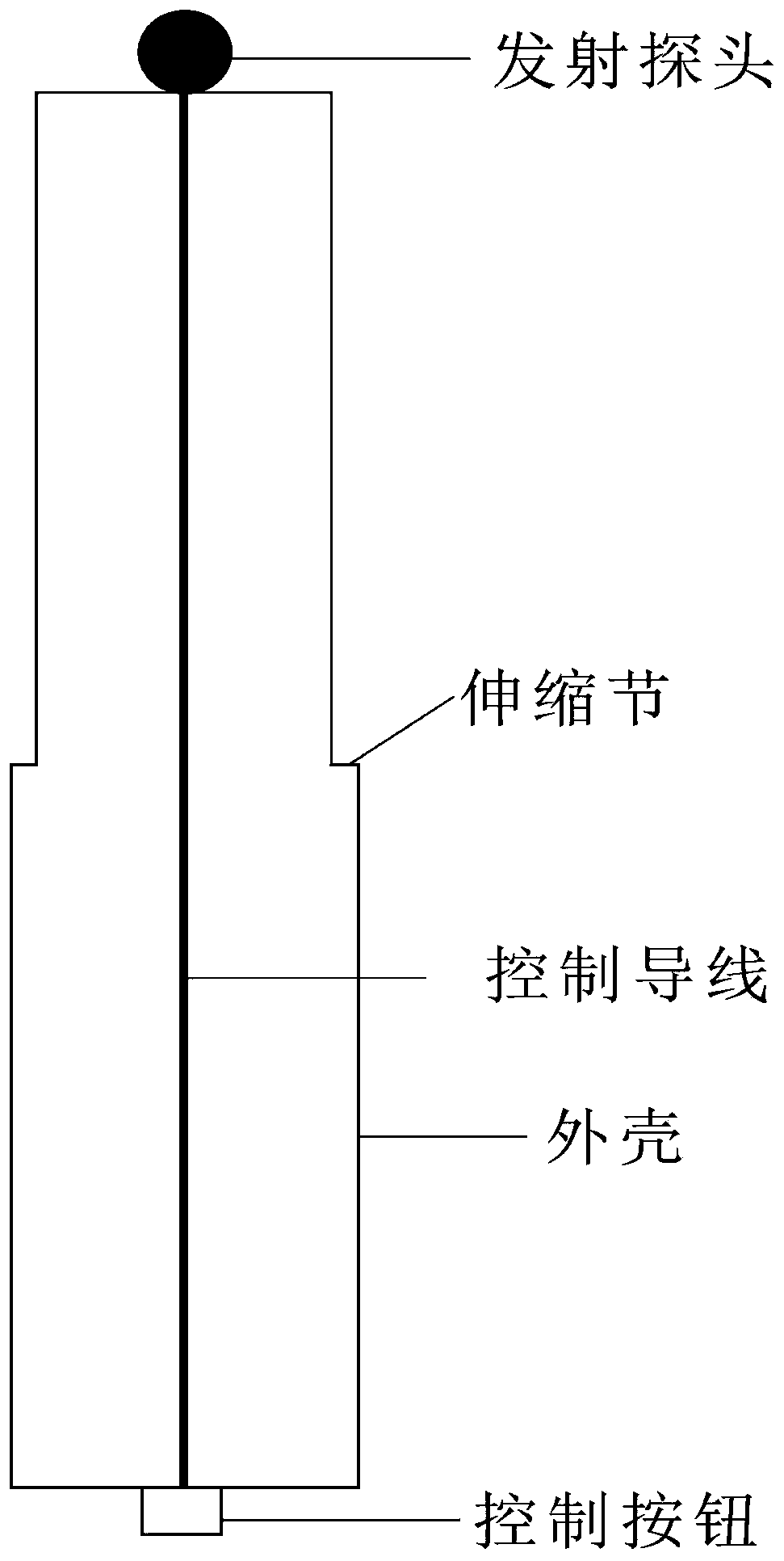

[0069] (2) Then the predetermined position 0(x 0 ,y 0 ,z 0 ) into a hole of a certain depth, and then insert the ultrasonic sending device to adjust the data processing interface of the notebook. Calculate the distance between each sensor and the ultrasonic transmission position according to the coordinates of each sensor and the coordinates of the ultrasonic transmission position, the calculation formula is as follows:

[0070]

[0071] (3) Press the button of the ultrasonic sending device to send ultrasonic waves, and at the same time when pressing, the timer of the ultrasonic sending device will count at the same time, and the initial output time is t 0 .

[0072] (4) After a pe...

Embodiment 2

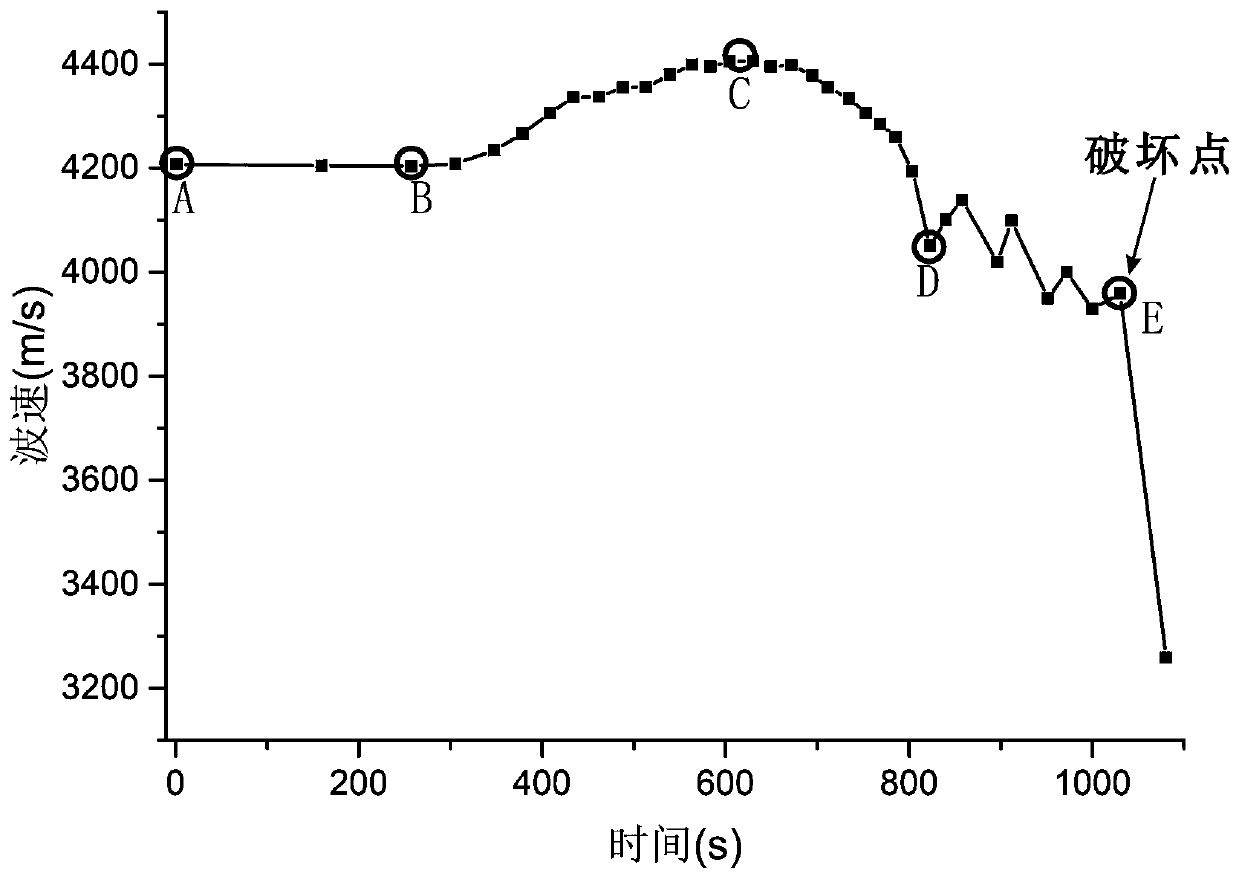

[0120] Acoustic wave is a good information carrier, and the acoustic wave velocity characteristics of rock media carry a large amount of information related to the mechanical properties and structural state of rock mass. These information can be comprehensively reflected in the changes of acoustic parameters, such as ultrasonic velocity, attenuation coefficient, waveform, frequency, frequency spectrum and amplitude, etc., through the analysis of the acoustic wave characteristics after the sound wave passes through the rock mass, it can be detected non-destructively, quickly and easily Structural properties of the interior of a rock mass. When the rock mass is affected by the excavation disturbance, the shape and size of the internal pores, cracks, and structural surfaces of the rock mass are constantly changing, and the propagation speed of the wave inside the rock mass will also change accordingly. According to the corresponding relationship, the present invention invents an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com