Combined heat and power generation unit heat burning cost determination method based on working condition analysis method

A technology of cogeneration unit and determination method, which is applied in heating mode, application, household heating and other directions, can solve problems such as changes, and achieve the effect of accurate determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail:

[0018] The method for determining the heat consumption cost of cogeneration units based on the working condition analysis method of the present invention comprises the following steps:

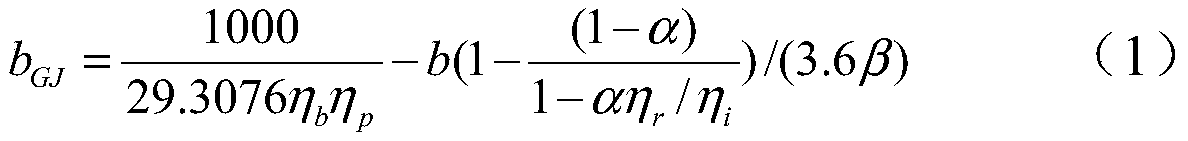

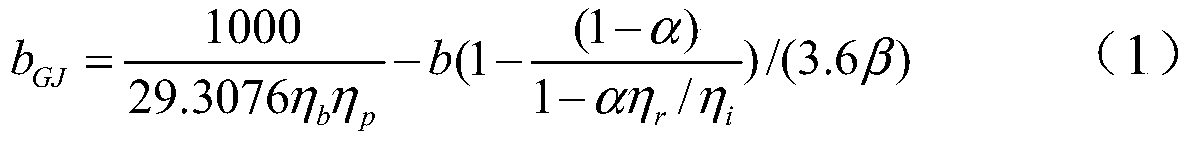

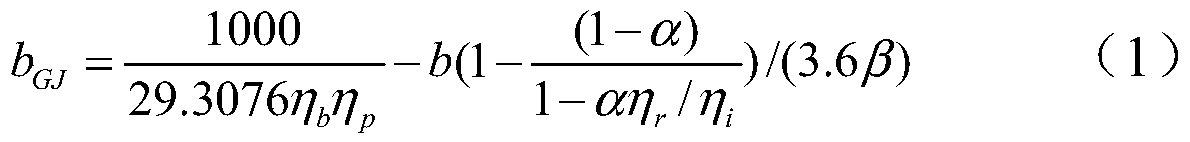

[0019] Coal consumption for heat supply of cogeneration units, according to the calorific method, refers to the amount of coal consumed for the same amount of heat. However, for cogeneration units, there is not only heat output, but also heat consumption, so the equivalent amount The amount of coal consumed by heat is deducted from the amount of coal saved in power generation compared with the pure condensate state as the coal consumption of the combined heat and power unit, and the standard coal consumption of the combined heat and power unit is obtained b GJ for:

[0020]

[0021] Among them, η b is boiler efficiency, η p is the pipeline efficiency, b is the pure condensate power generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com