Flexible direct-current power transmission system MMC sub-modules key element synchronous online monitoring method

A power transmission system, flexible DC technology, applied in the direction of electrical components, AC power input conversion to DC power output, power transmission AC network, etc., can solve the problem of increasing computer memory burden, increasing input costs, and unused IGBT on-state voltage aging judgment Basis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

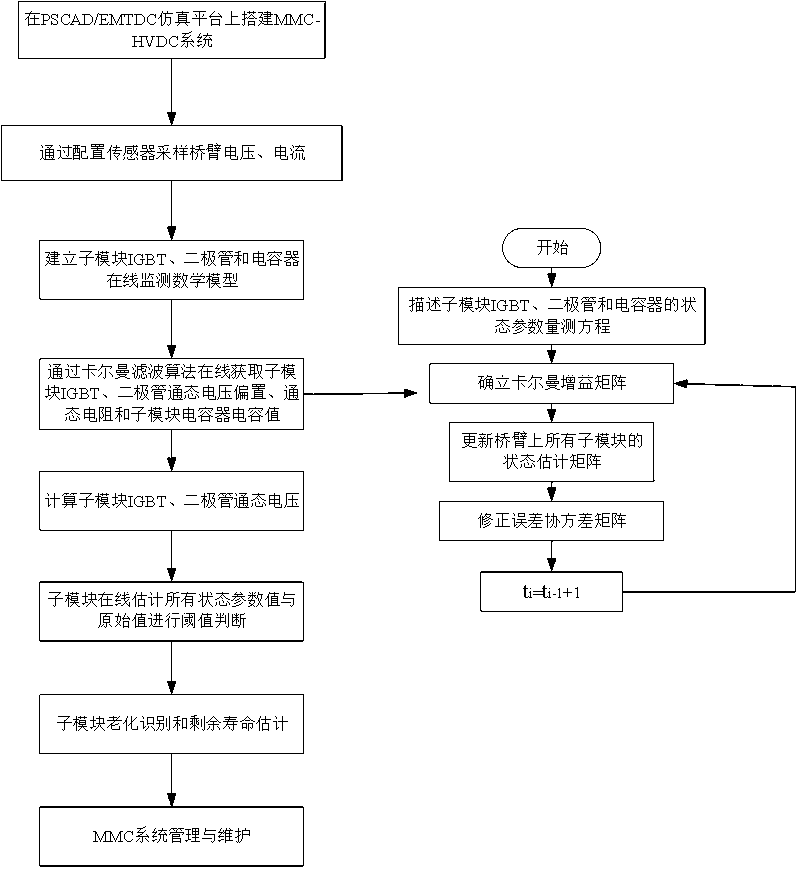

[0088] Please refer to Figure 6 , the present invention provides a method for synchronous online monitoring of key components of the MMC sub-module of the flexible direct current transmission system, comprising the following steps:

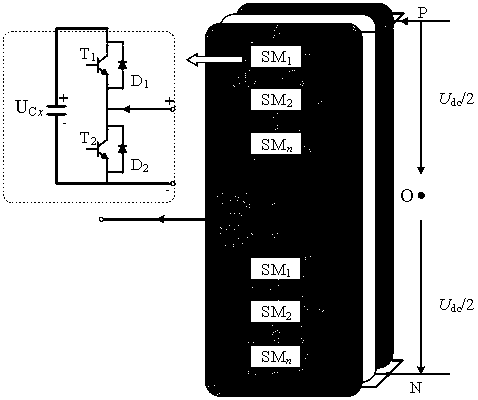

[0089] Step S1: build MMC-HVDC system;

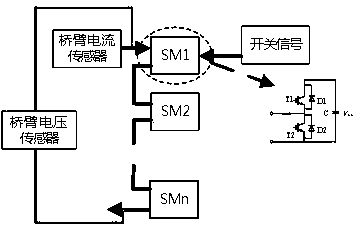

[0090] Step S2: obtain bridge arm voltage, current and submodule capacitance voltage by configuring sensor;

[0091] Step S3: build submodule IGBT, diode and capacitor online monitoring mathematical model;

[0092] Step S4: online acquisition of IGBT, diode on-state voltage bias, diode on-state resistance and capacitor capacitance by Kalman filter algorithm;

[0093] Step S5: Calculate the estimated on-state voltage according to the diode on-state voltage bias and the diode on-state resistance, and calculate the on-state voltage and the on-state resistance respectively;

[0094]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com