Agricultural machine used for threshing

A technology of agricultural machinery and arc conveyor belt, applied in agricultural machinery and implements, agriculture, threshing equipment, etc., can solve the problems of non-adjustable threshing strength, slow action of beating components, affecting threshing sufficiency, etc., so as to improve threshing strength and strengthen Rolling effect, adjustable intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

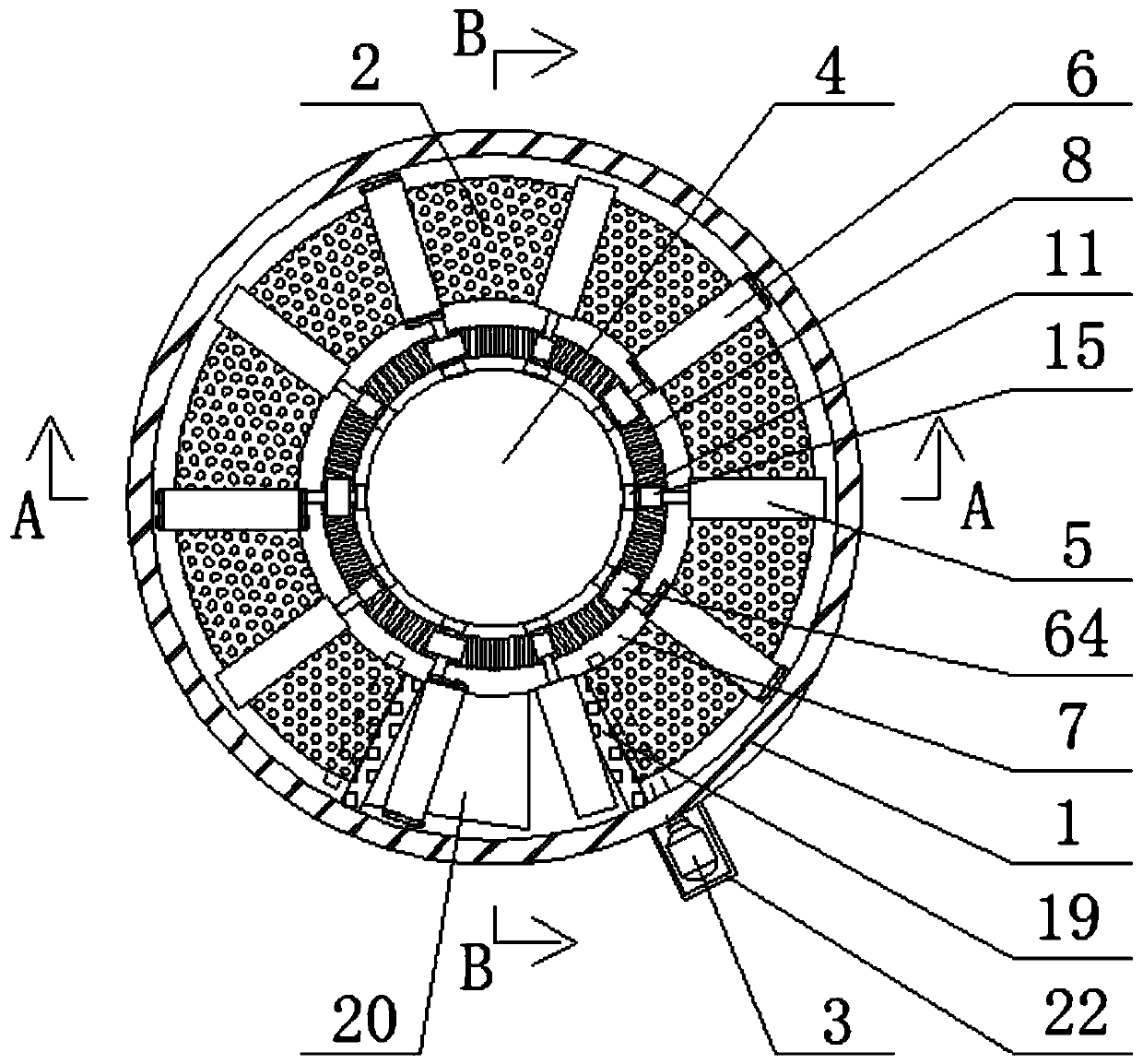

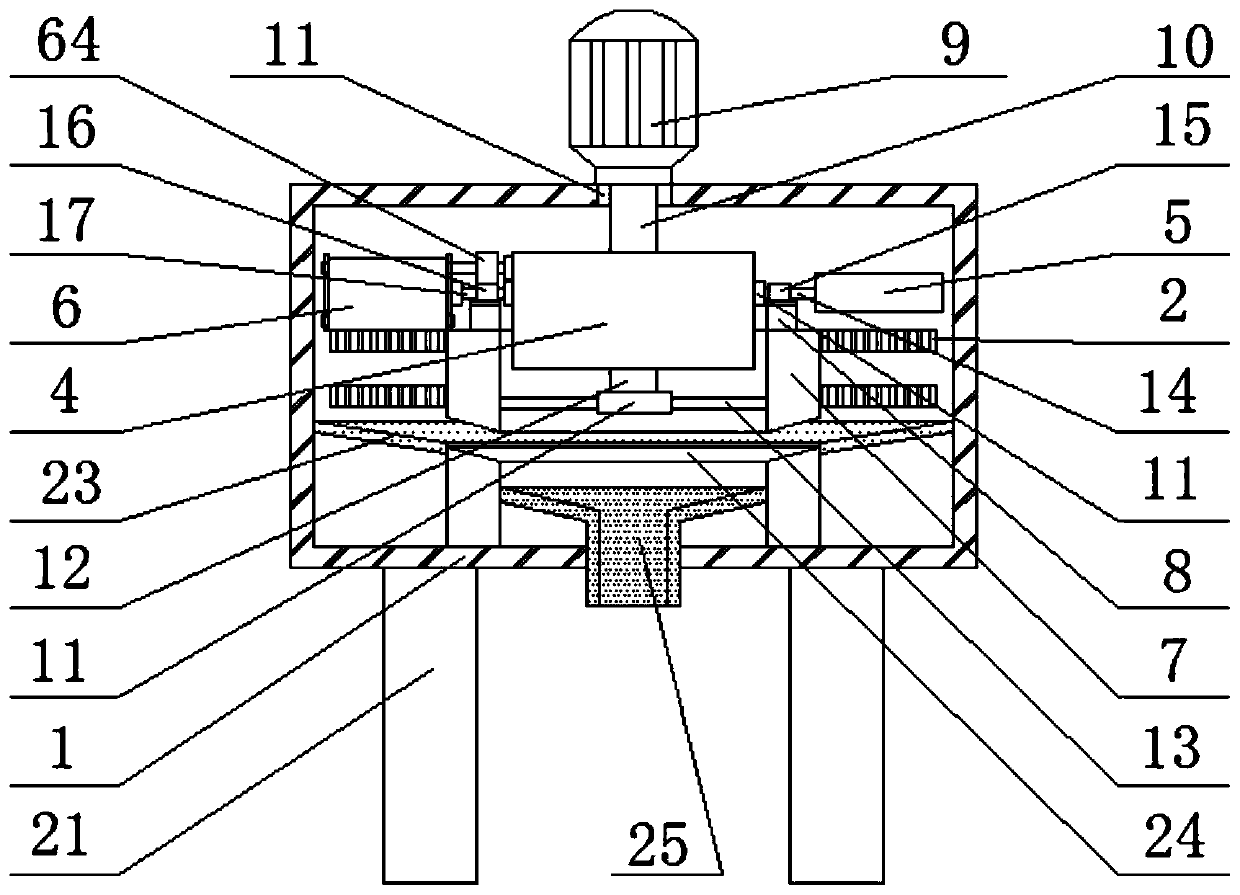

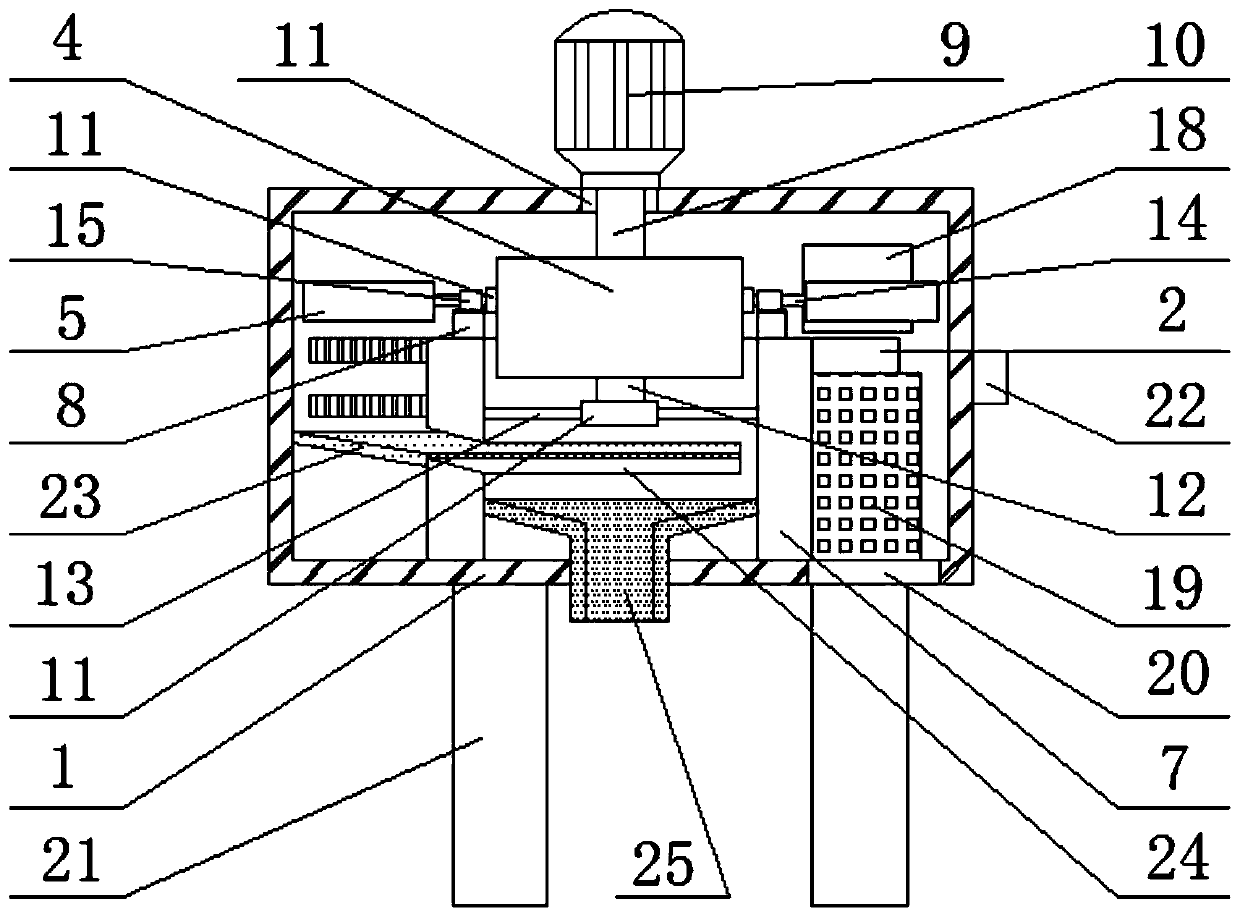

[0031] Such as figure 1 The shown agricultural machinery for threshing includes an outer box body 1, a conveyor belt loading module and a rolling threshing module; the conveyor belt loading module includes an arc conveyor belt 2 and a first motor 3 that drives the arc conveyor belt 2 to run, The corresponding central angle of the arc conveyor belt 2 is not less than 180 ° (the corresponding central angle of the arc conveyor belt 2 shown in the figure is about 300 °), and the arc conveyor belt 2 is evenly distributed with nets for beans to pass through. hole;

[0032] The rolling threshing module includes a central rotating column 4 vertically arranged at the center of the arc conveyor belt 2, at least three pressure rollers 5 distributed at equal intervals along the circumference of the central rotating column 4 and located in the radial direction of the central rotating column 4, At least three sets of loosening assemblies 6 distributed at equal intervals along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com