Halal cattle slaughtering and segmenting process

A technology of slaughter division and process, applied in the direction of slaughter, slaughter accessories, slaughter devices, etc., can solve the problems of lack of reasonable requirements for slaughter steps, and achieve the effects of improving digestion efficiency, reducing food accumulation, and promoting digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

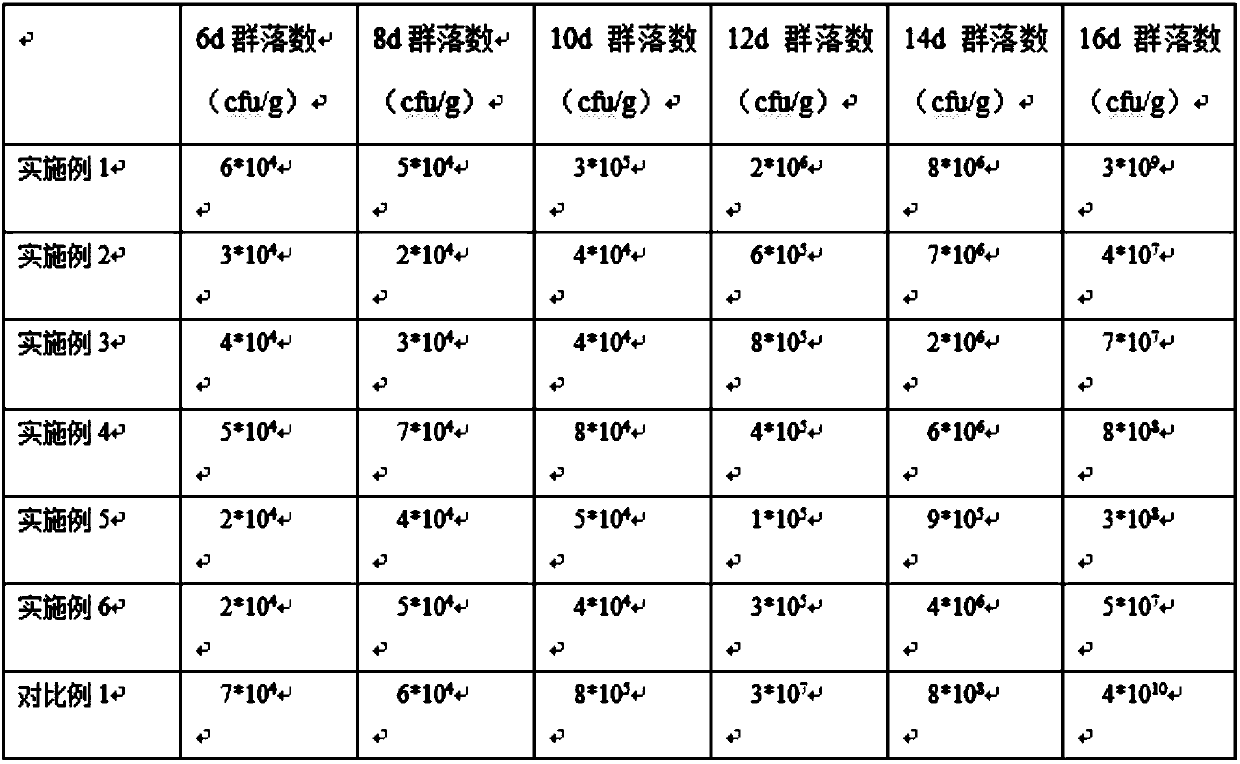

Examples

preparation example 1

[0037] Preparation example 1, the preparation method of cleaning solution, comprises the steps:

[0038] Step 1: Pulverize the tulip powder to 10 μm with an ultrafine pulverizer;

[0039] Step 2: Mix cinnamon essential oil 8Kg, clove essential oil 8Kg, tulip powder 10Kg, amomum essential oil 7Kg, and rosemary essential oil 5Kg to obtain the antibacterial additive;

[0040] Step 3: Add 12Kg of antibacterial additive to 1000Kg of water.

preparation example 2

[0041] Preparation example 2, the preparation method of cleaning solution, comprises the steps:

[0042] Step 1: Pulverize the tulip powder to 10 μm with an ultrafine pulverizer;

[0043] Step 2: Mix 3Kg of cinnamon essential oil, 3Kg of clove essential oil, 4Kg of tulip powder, 1Kg of amomum essential oil and 1Kg of rosemary essential oil to obtain the antibacterial additive;

[0044] Step 3: Add 4Kg of antibacterial additive to 1000Kg of water.

preparation example 3

[0045] Preparation example 3, the preparation method of cleaning solution, comprises the steps:

[0046] Step 1: Pulverize the tulip powder to 10 μm with an ultrafine pulverizer;

[0047] Step 2: Mix 5.5Kg of cinnamon essential oil, 5.5Kg of clove essential oil, 7Kg of tulip powder, 4Kg of amomum essential oil, and 3Kg of rosemary essential oil to obtain the antibacterial additive;

[0048] Step 3: Add 8Kg of antibacterial additives to 1000Kg of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com