A compact food processor

A technology for a food processing machine and a stand, which is applied to utensils with integral electric heating devices, kitchen utensils, household utensils, etc., can solve the problems of insufficient compact structure of food processing machines, complex structure of mixing cup components, and performance discounts such as waterproofing. , to achieve the effect of good waterproof and dustproof performance, compact and reasonable layout, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

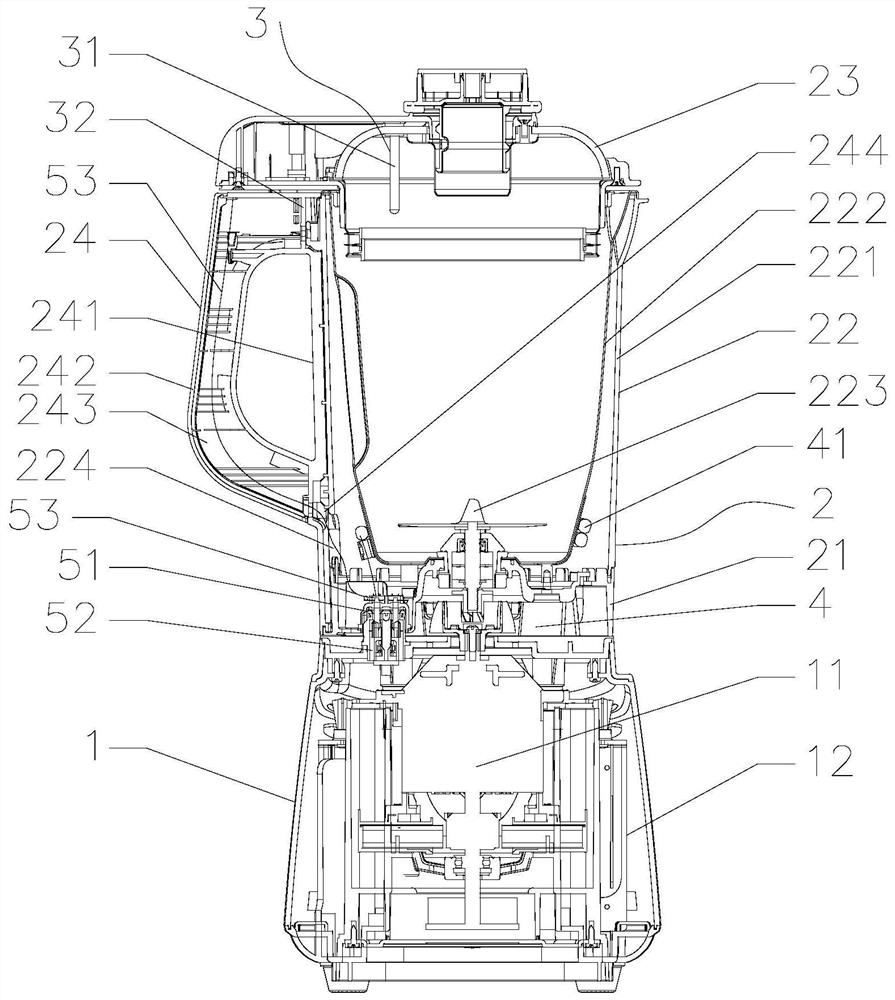

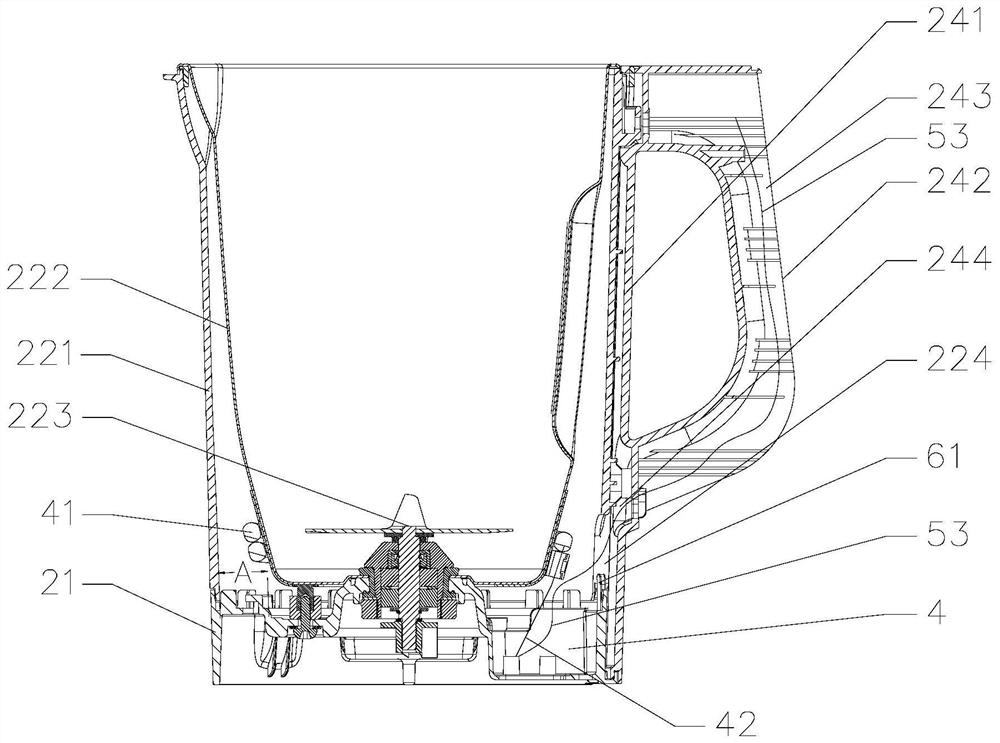

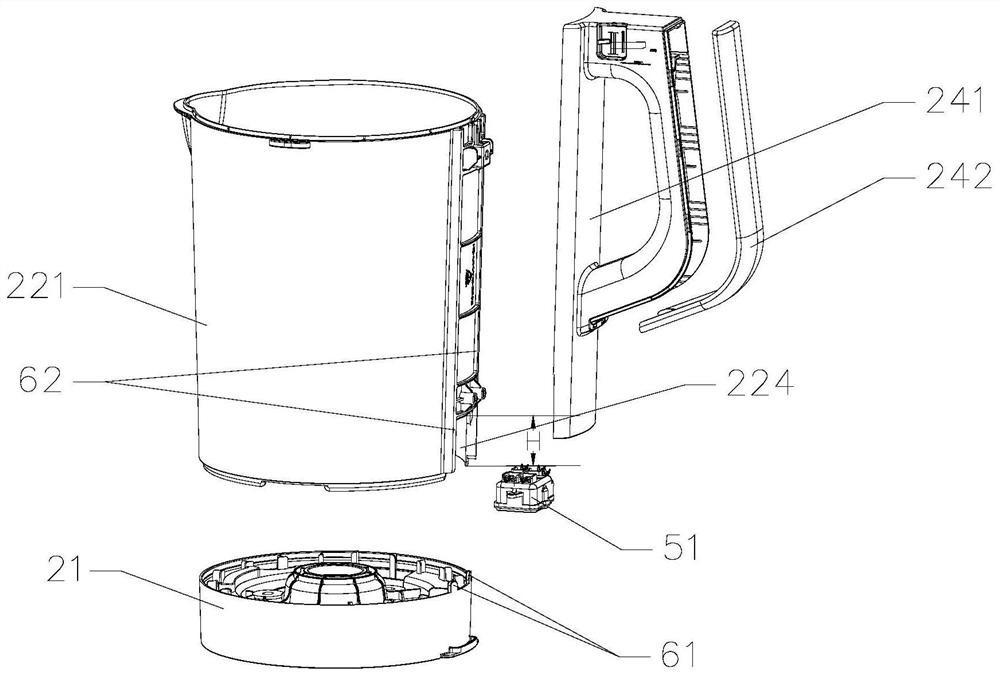

[0034] The structure of the food processor of this embodiment is as follows Figure 1 to Figure 3 As shown, the food processing machine includes a base 1, a stirring cup assembly 2 arranged on the base 1, and a detection device 3 arranged on the upper part of the stirring cup assembly 2. The base 1 is provided with a motor 11 and a circuit board 12 to stir The cup assembly 2 includes a cup base 21, a cup body 22 and a cup cover 23. The cup body 22 includes an outer cup body 221 and an inner cup body 222. The inner cup body 222 is provided with a crushing knife 223. The upper end of the motor shaft of the motor 11 runs through the machine. A lower connector is connected to the back of the base 1, and an upper connector is connected to the lower end of the cutter shaft of the crushing knife 223. When the stirring cup assembly 2 is placed in place on the base 1, the upper connector and the lower connector are matched and connected, so that the motor 11 can operate. The pulverizin...

Embodiment 2

[0053] The difference between this embodiment and the first embodiment is that the structure of the conductive member 53 is different. Figure 4 As shown, the conductive member 53 in this embodiment includes a wire 531 and a conductive sheet 532. The conductive sheet 532 is in the shape of a sheet. A clamping cavity 245 is formed between the handle body 241 and the outer cup body 221. The conductive sheet 532 is located in the clamping cavity 245. One end of the wire 531 extends into the annular cavity 4 and is electrically connected to the first coupler 51. The other end of the wire 531 extends out of the annular cavity and is connected to the conductive sheet 532. The conductive sheet 532 extends upward along the clamping cavity and is electrically connected to the detection device. The installation method is very suitable for the arrangement and installation of the rigid conductive member ie the conductive sheet 532 , and the rigid conductive member ie the conductive sheet 5...

Embodiment 3

[0056]The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the structure of the detection device is different. Figure 5 As shown, the detection device 3 includes a detection switch 33 and a trigger member 34 that triggers the detection switch 33. The trigger member 34 is arranged on the cup cover 23, specifically on the mounting seat on one side of the cup cover 23, and the detection switch 33 is arranged on the handle The top of 24 is electrically connected to the conductive member 53. After the cup cover is installed in place, the mounting seat is located above the top of the handle 24. The trigger member 34 triggers the detection switch 33, and the detection switch 33 feeds back to the circuit board 12. The internal circuit of the food processor is turned on to improve the safety of the user. In this embodiment, the detection switch 33 is a micro switch, and the trigger member 34 is a contact, that is, whether the lid is closed in place can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com