Stirring reaction device suitable for strong corrosive gas to participate in reaction

A reaction device, strong corrosion technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the strict requirements of sealing systems, reactor damage, fluorine To avoid problems such as low chemical efficiency, avoid local high temperature or local excessive fluorination, prolong service life, and prevent direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

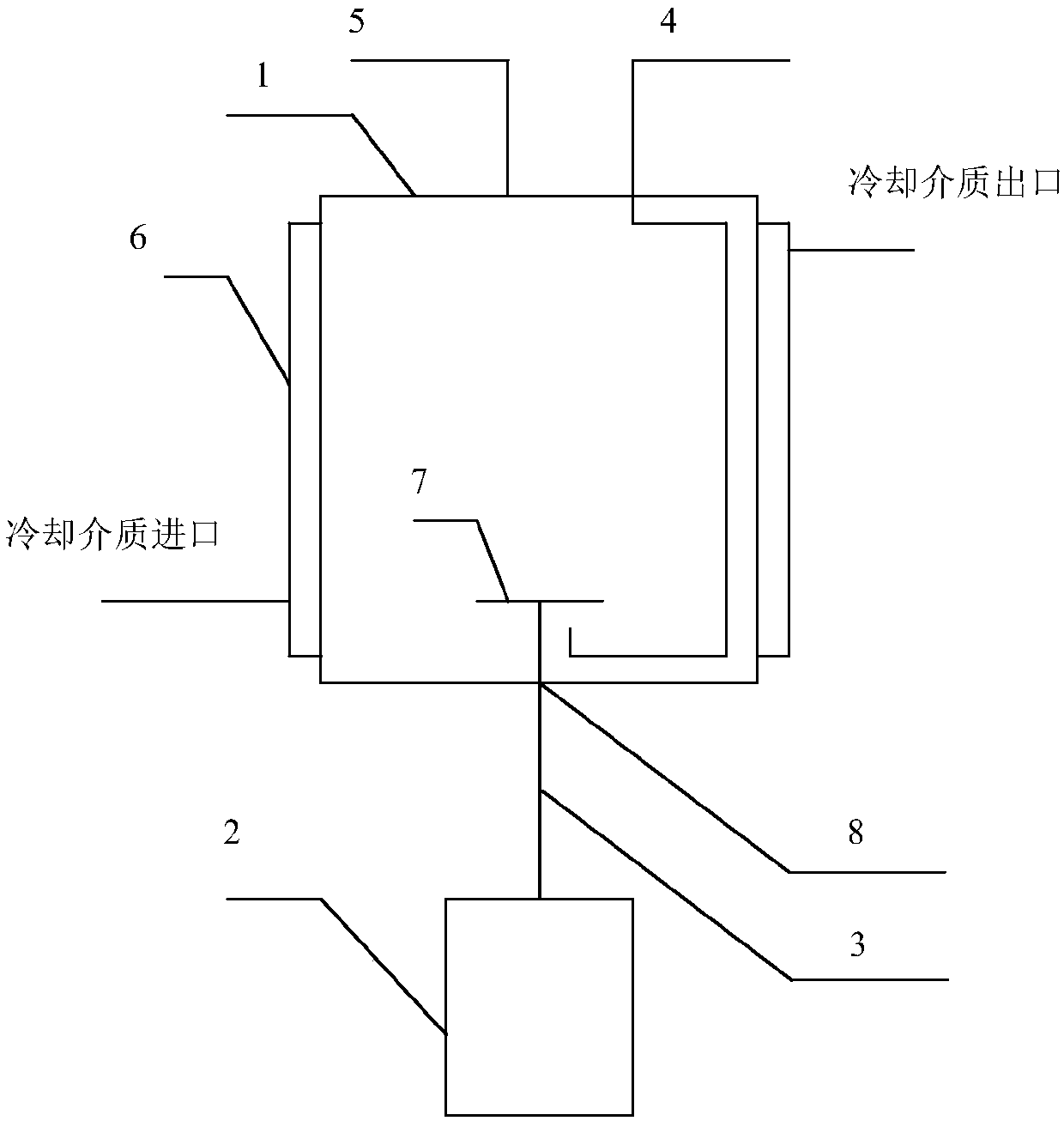

[0030] This embodiment relates to a stirring reaction device suitable for strong corrosive gases to participate in the reaction, such as figure 1 As shown, the reaction device includes a reactor 1, a strong corrosive gas inlet conduit 4, a strong corrosive gas outlet 5, an insulating liquid and an agitator 7 for stirring the insulating liquid;

[0031] The drive shaft 3 of the agitator extends into the reactor 1 from the bottom of the reactor 1, and the seal 8 between the drive shaft 3 and the reactor 1 is located in the spacer liquid, the The strong corrosive gas inlet conduit 4 extends below the liquid level of the spacer liquid, and its gas outlet does not contact the seal 8, and the strong corrosive gas gas outlet 5 is located above the liquid level of the spacer liquid; The spacer fluid does not react with the strong corrosive gas.

Embodiment 2

[0033] This embodiment relates to a stirring reaction device suitable for strong corrosive gases to participate in the reaction. Compared with Embodiment 1, the difference is that the inlet conduit 4 of the strong corrosive gas runs along the inner wall of the reactor 1 to the bottom, And the opening is located upwards from the projected position of the stirring blade of the stirrer. The inside of the reactor is provided with one or more temperature sensors, and the outer wall of the reactor is provided with a thermal insulation jacket 6, and the temperature sensor is connected with the thermal insulation jacket 6, and is connected to the thermal insulation jacket. Send temperature signal.

Embodiment 3

[0035] This embodiment relates to a stirring reaction device suitable for strong corrosive gases to participate in the reaction. Compared with Embodiment 1, the difference is that the seal at the connection between the drive shaft and the reactor is made of Monel or Hastelloy The reactor is made of stainless steel or nickel alloy, and the reactor of the present invention is also provided with a material inlet and a material outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com