A steel pipe paint removal device for construction

A technology for construction and steel pipes. It is applied in the direction of manufacturing tools, grinding machine parts, grinding machines, etc. It can solve the problems of inability to guarantee the quality of steel pipe paint removal, waste of manpower and material resources, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is realized through the following technical solutions:

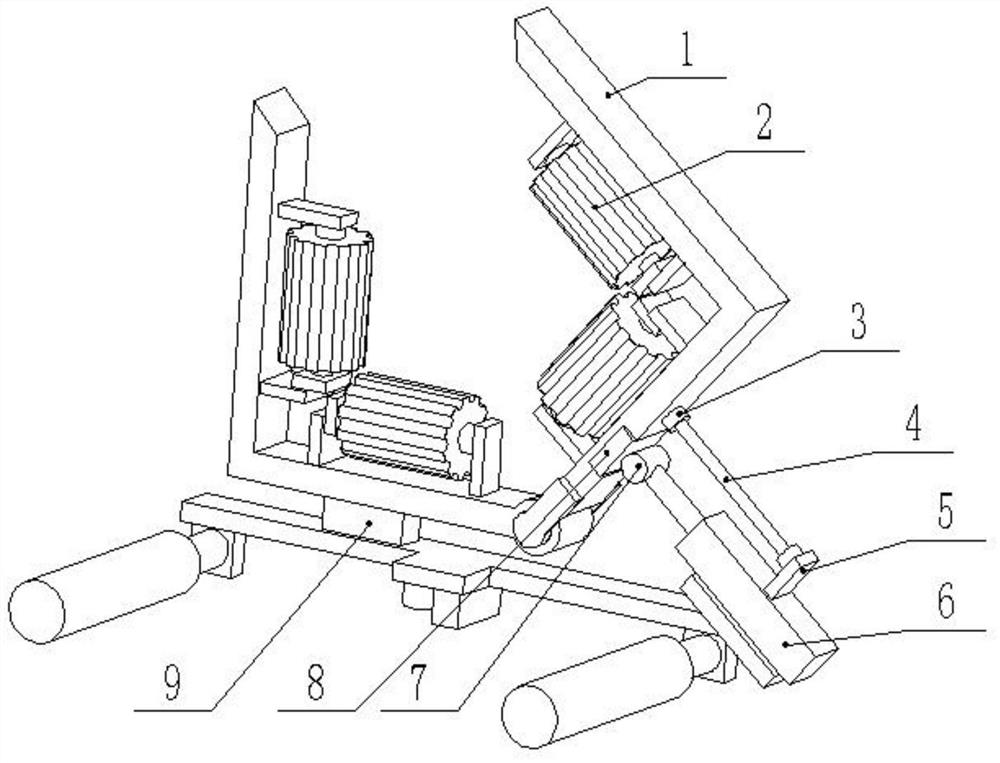

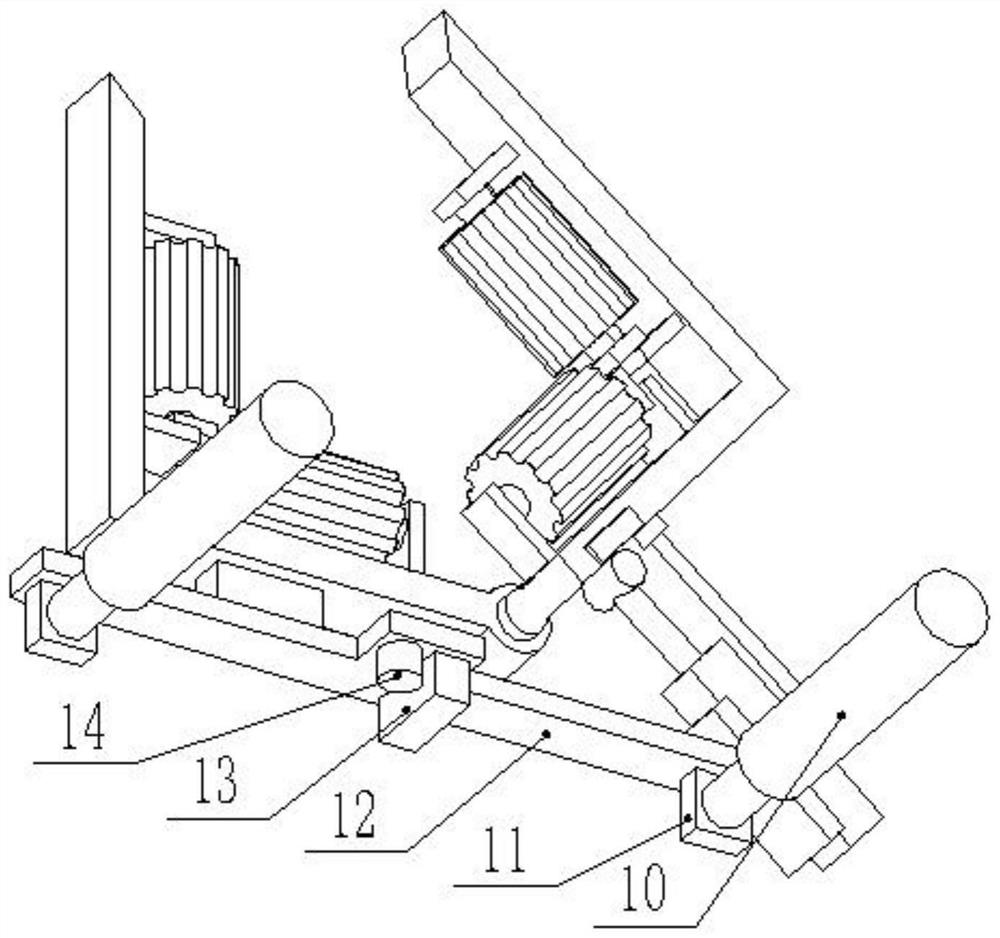

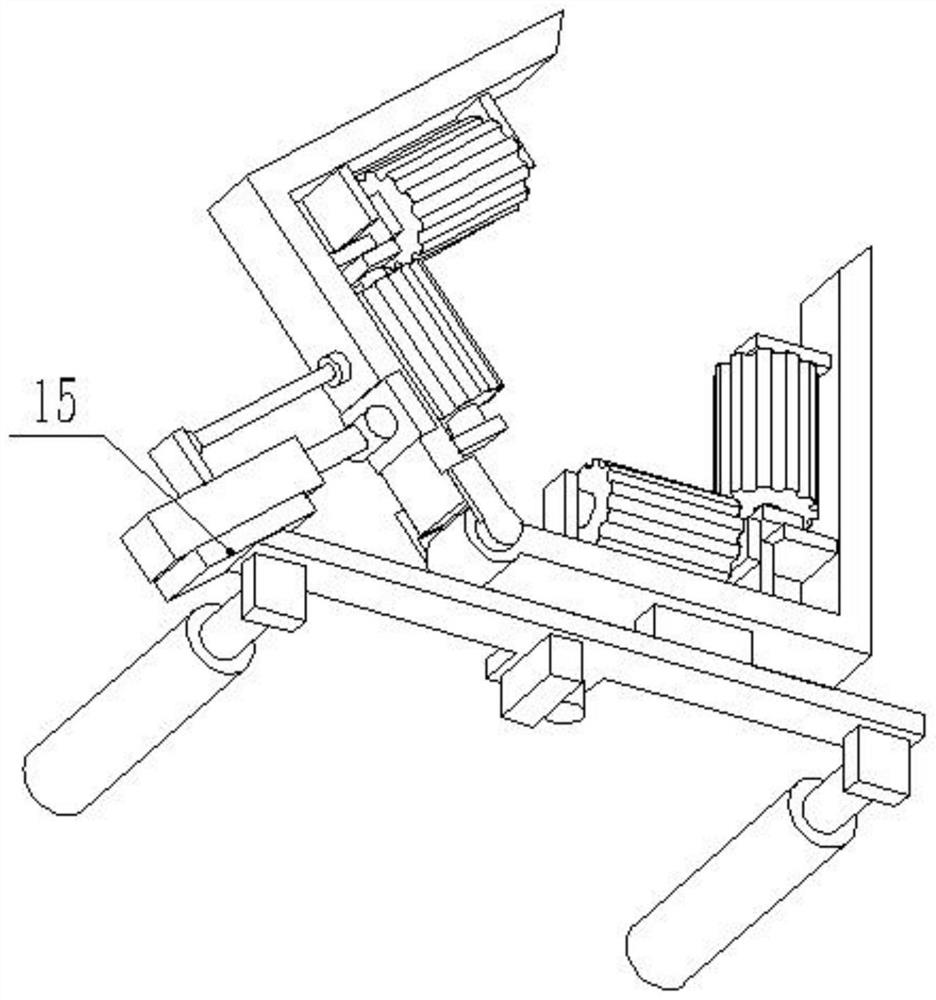

[0019] A steel pipe paint removal device for construction, comprising a support device 1, a friction device 2, a rubber band base 3, a rubber band 4, a first support 5, a hydraulic cylinder 6, a friction base 7, a pressure sensor 8, a second support 9, Hand-held support 10, the 3rd support 11, the 4th support 12, hydraulic cylinder driver 13, controller 14 and the 5th support 15, described support device 1 is installed on the second support 9 top, and described friction device 2 has four , which are respectively installed on the movable support 101 and the static support 103 on the left and right sides of the support device 1, and are used to polish the steel pipe and carry out the steel pipe paint removal operation. The rubber band base 3 is fixed on the outside of the movable support 101, and the rubber band 4 is installed on the rubber band Between the base 3 and the first bracket 5, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com