A paint removal device for waste paint buckets

A technology for paint buckets and paints, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as environmental secondary pollution, physical hazards to workers, and influence on brushing efficiency, so as to reduce loss and Pollution rate, effect of improving paint removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

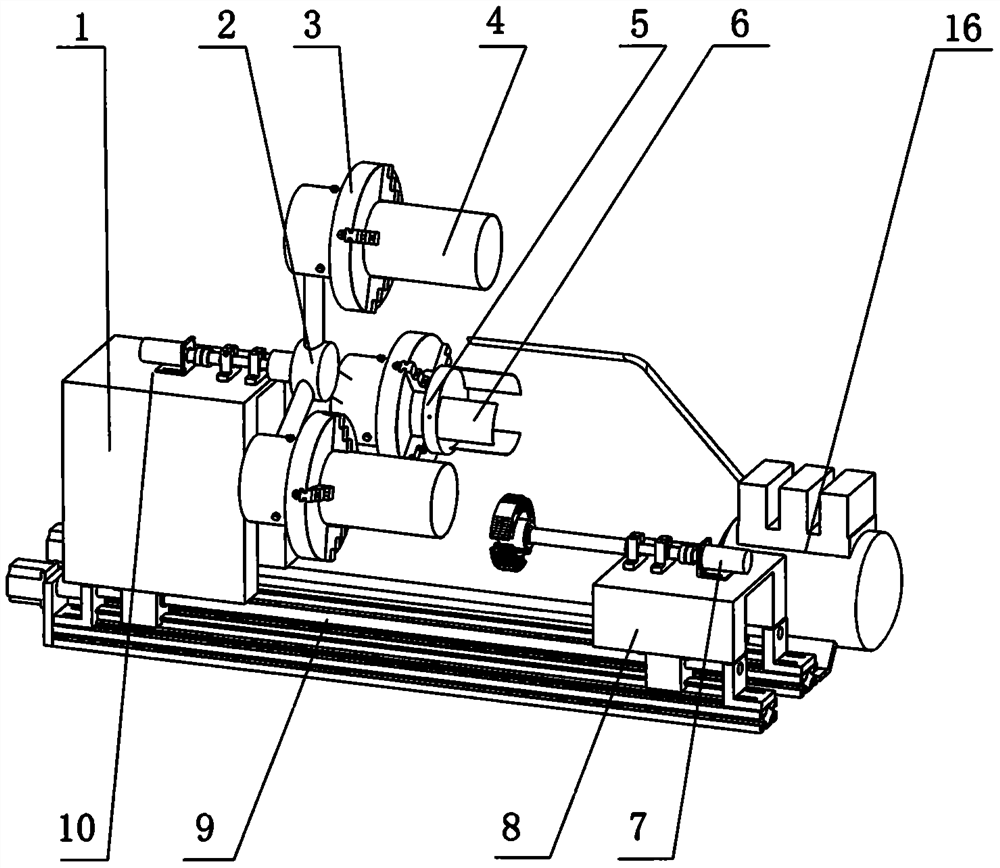

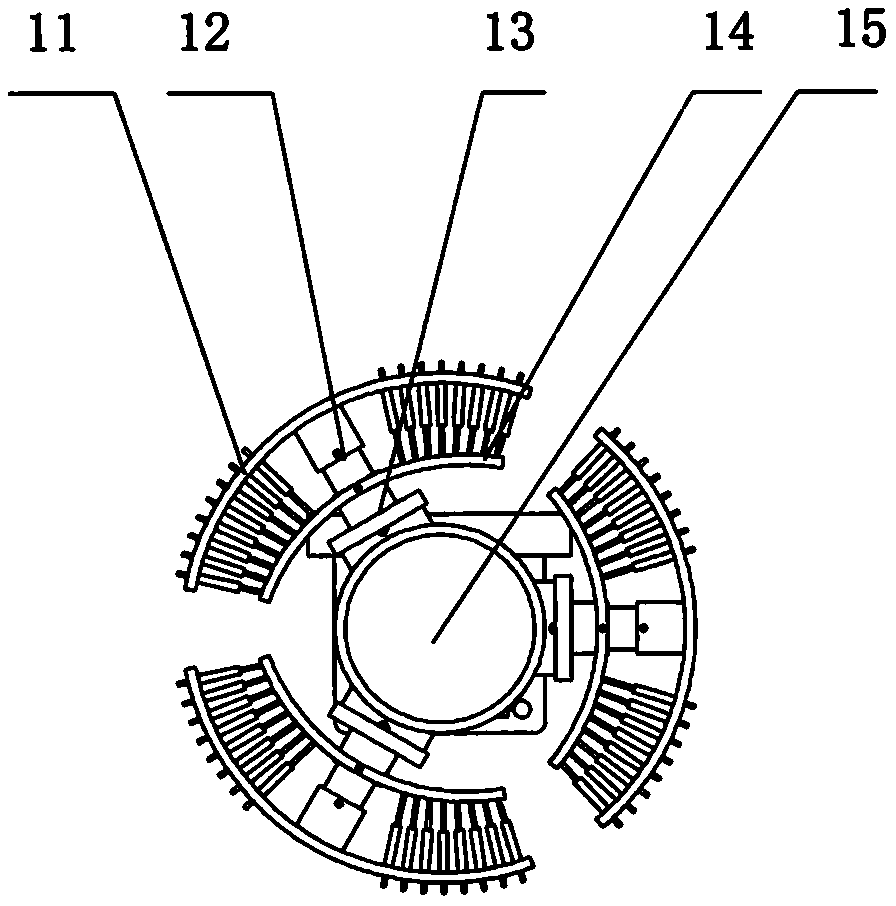

[0017] A paint removal device for waste paint buckets, comprising a paint bucket workbench 1, a paint bucket fixing frame 2, a four-claw chuck 3, a paint bucket 4, a paint scraper knife holder 5, a paint scraper 6, a brush handle control motor 7, Brush workbench 8, linear guide screw slide module 9, paint bucket fixing frame control motor 10, brush cover 11, electric push rod 12, electric push rod cover 13, brush 14, brush handle 15, pressure washer 16.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com