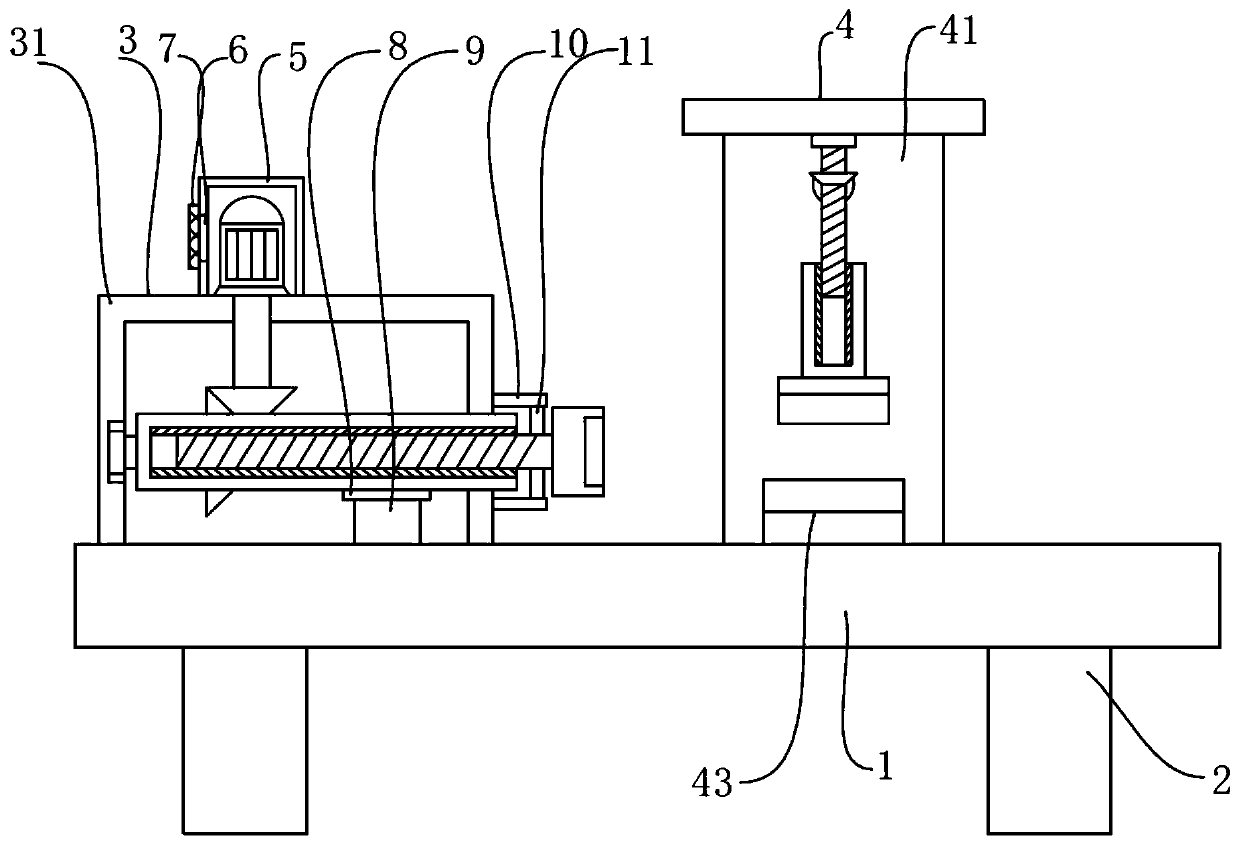

Mechanical processing platform for pipe fitting processing

A technology for machining platforms and pipe fittings, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of reduced processing efficiency, increased production cost, inconvenient use, etc., and achieve the goal of improving processing efficiency, reducing labor intensity, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

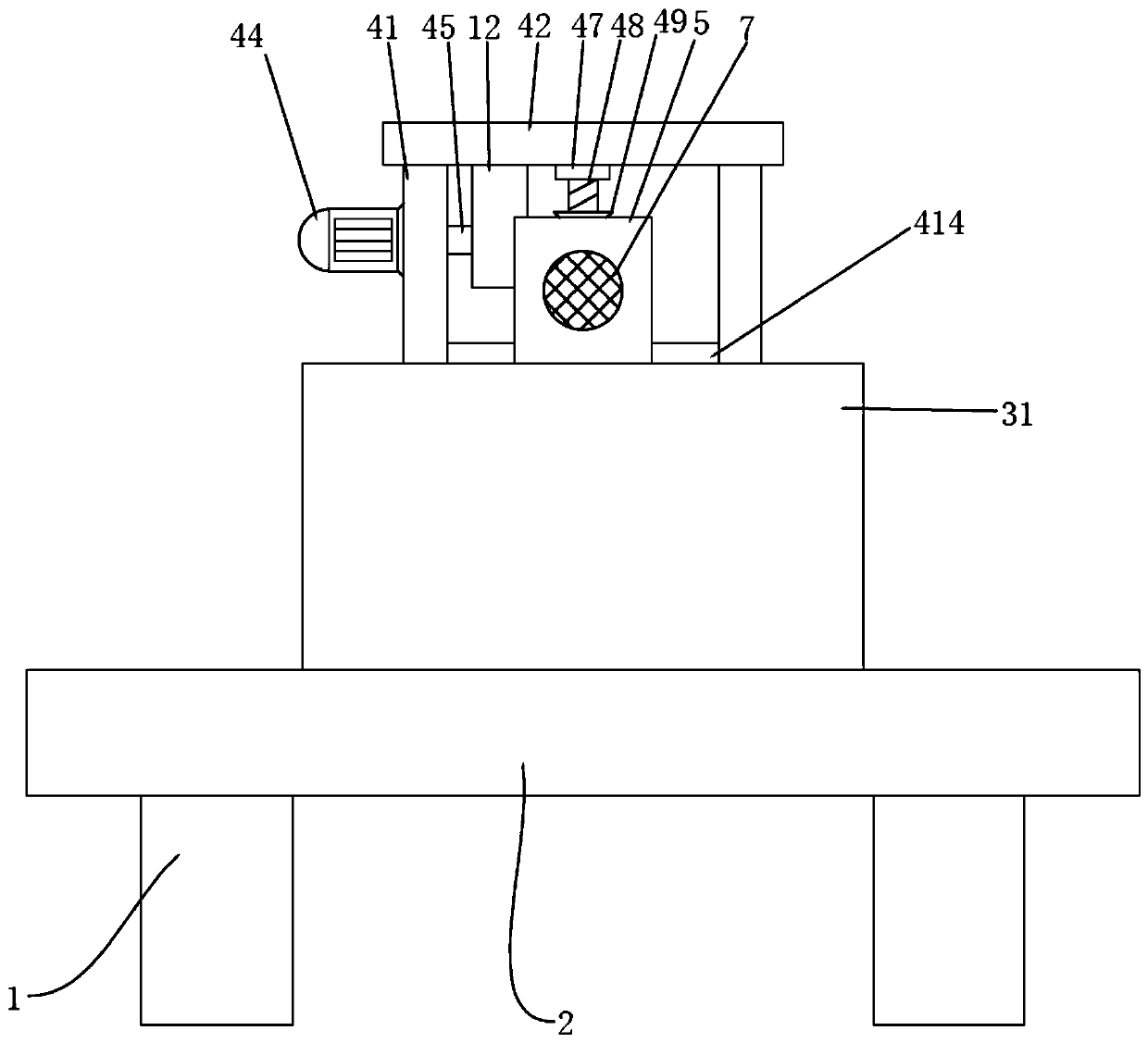

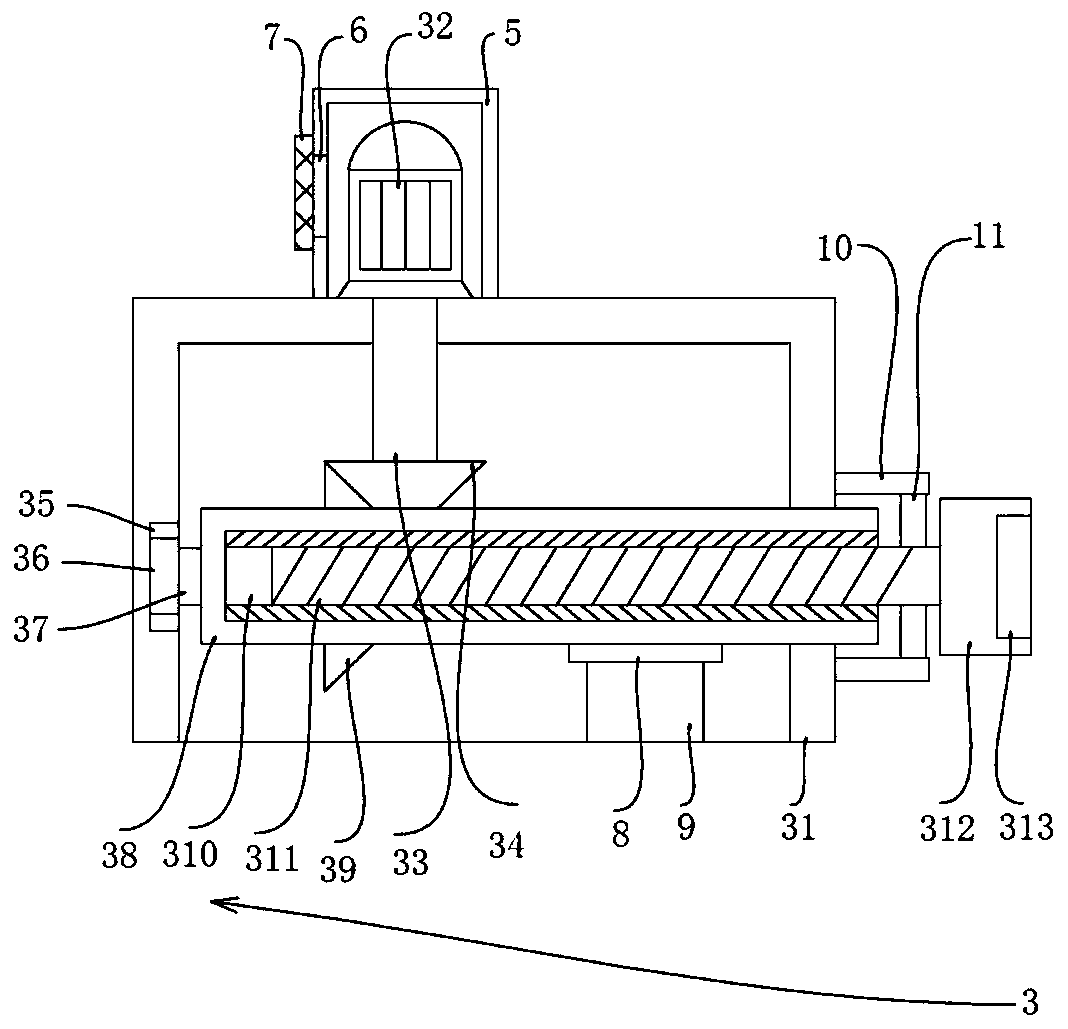

Embodiment 1

[0025] By cooperating with the third threaded groove 415 and the third threaded shaft 416, the effect of facilitating the replacement of the second clamping block 417 is played. The second clamping block 417 can be replaced according to the size of the pipe diameter, and the rotating motor 44 is started, and the rotating motor 44 drives the third gear 46 to rotate by rotating shaft 45, and the third gear 46 drives the fourth gear 49 that meshes with it to rotate, and the fourth gear 49 drives the second threaded shaft 48 to rotate, because the second threaded shaft 48 and the second thread groove 411 is threaded, and the clamping shaft 410 is limited by the chute 412 and the slider 413, so that the clamping shaft 410 drives the second clamping block 417 to move downward, and the first clamping block 43 and the second clamping block 417 Cooperate with each other to clamp the pipe fittings.

Embodiment 2

[0027] Put the pipe between the first clamping block 43 and the second clamping block 417, the left end of the pipe extends into the inside of the fixing groove 313, then start the rotating motor 44, and the rotating motor 44 drives the third gear 46 to rotate through the rotating shaft 45 , the third gear 46 drives the second threaded shaft 48 to rotate through the fourth gear 49, because the second threaded shaft 48 is threadedly connected with the second threaded groove 411, and the clamping shaft 410 is limited by the chute 412 and the slider 413, so that The clamping shaft 410 drives the second clamping block 417 to move downward, and the first clamping block 43 cooperates with the second clamping block 417 to clamp the pipe, and then process the pipe. , the rotating motor 44 drives the rotating shaft 45 to rotate in reverse, so that the clamping shaft 410 drives the second clamping block 417 to move upward, and then starts the driving motor 32, and the driving motor 32 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com