High-quality prestressed steel cylinder concrete pipe and production process thereof

A steel cylinder concrete and prestressed steel technology, applied in the direction of pipes, rigid pipes, manufacturing tools, etc., can solve the problems of lack, easy to slip, reduce the prestress of steel cylinder concrete pipes, etc., to improve work efficiency and improve sealing performance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

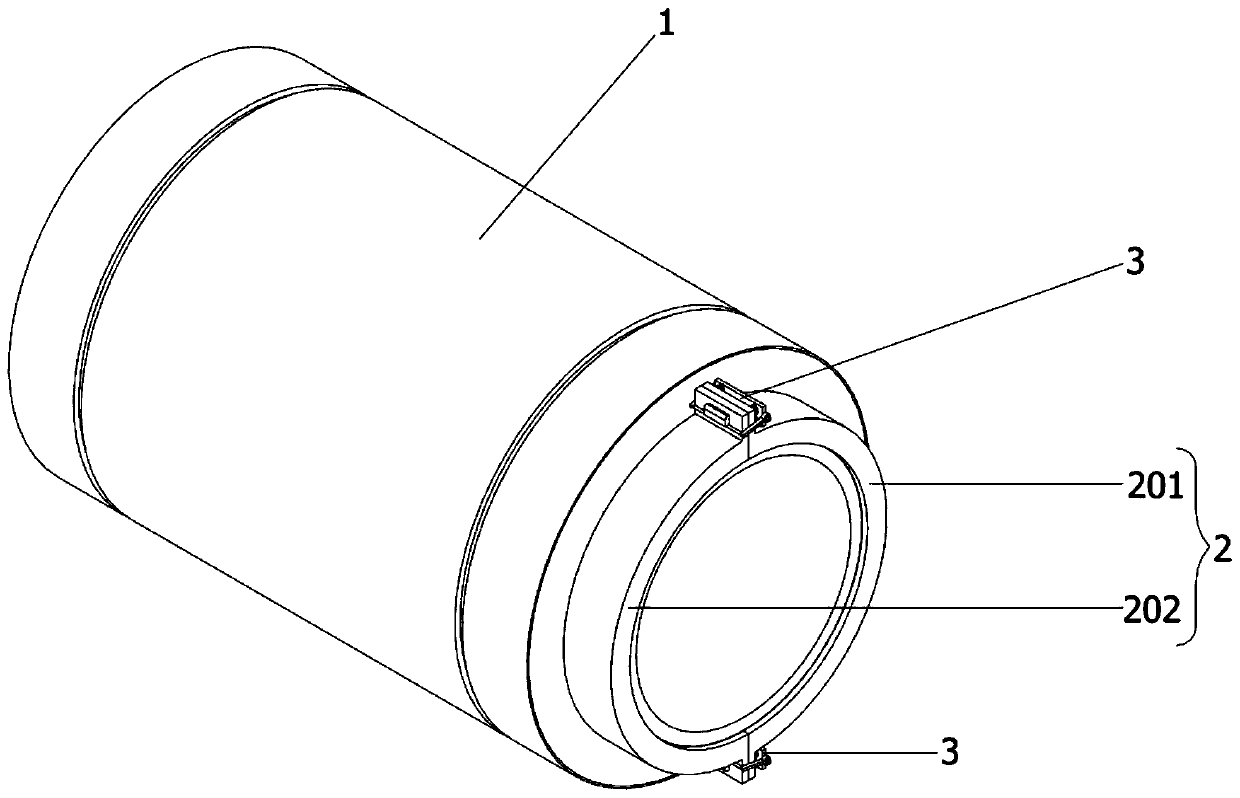

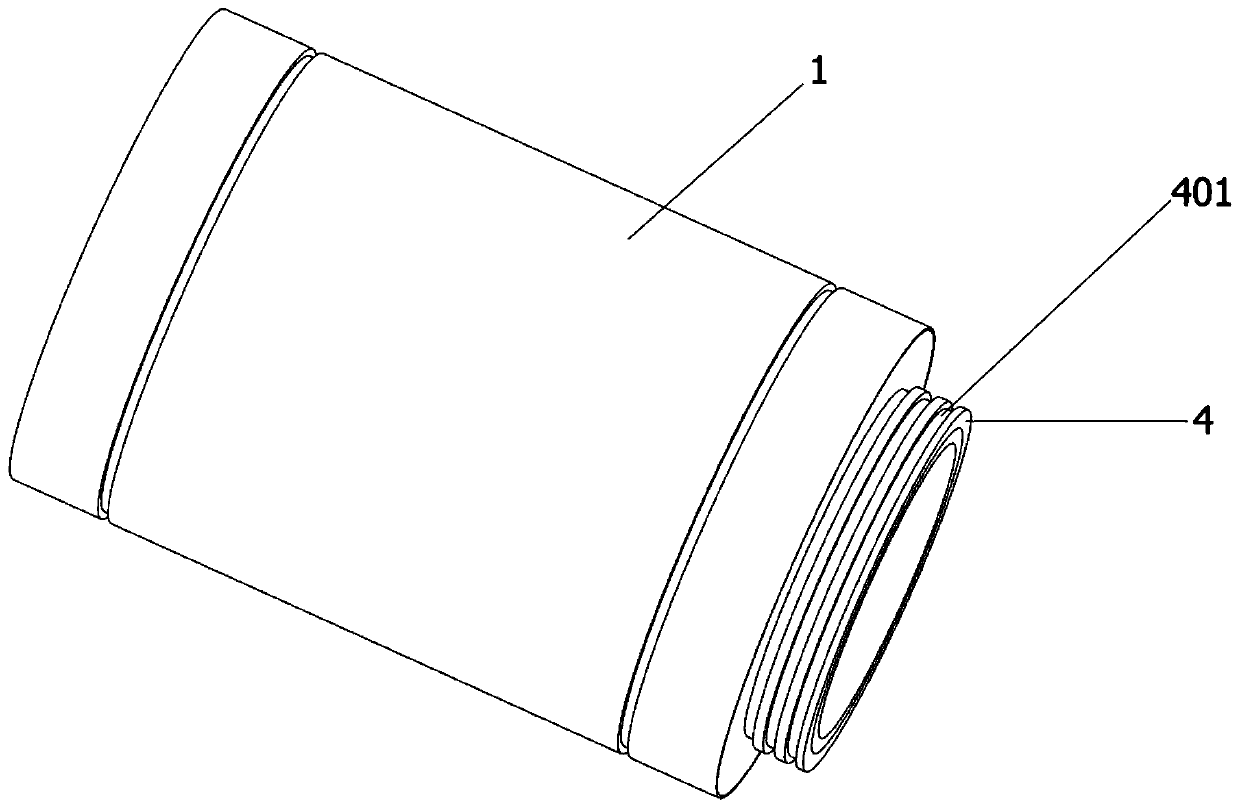

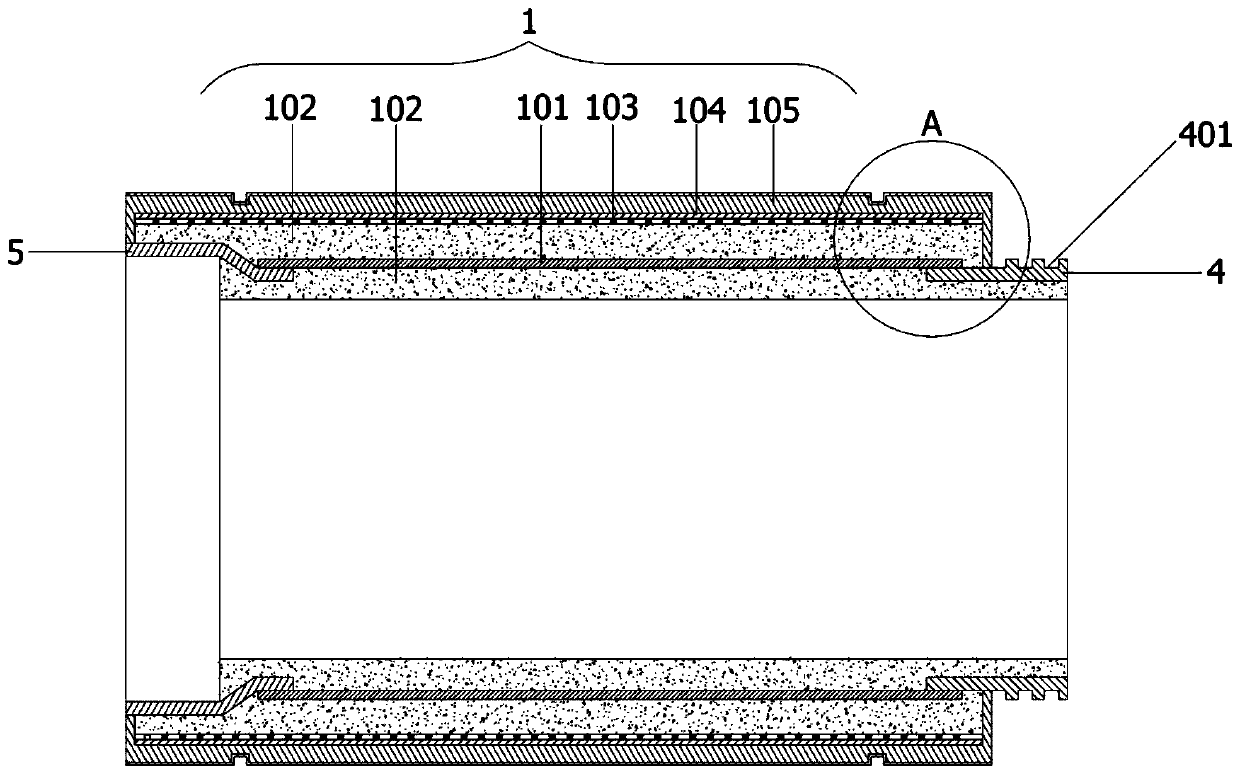

[0040] as attached figure 1 to attach Figure 8 Shown:

[0041] The invention provides a high-quality prestressed steel cylinder concrete pipe and its production process, including: a steel cylinder concrete pipe 1, the left and right ends of the steel cylinder concrete pipe 1 are respectively welded with a socket steel ring 5 and a socket steel ring 4, the socket The steel ring 4 also includes a second annular groove 401. Two second annular grooves 401 are provided on the outer peripheral surface of the socket steel ring 4, and the depth of the two second annular grooves 401 accounts for half of the thickness of the right end of the socket steel ring 4. One; the outside of the socket steel ring 4 is fastened with a protective mechanism 2, and the protective mechanism 2 also includes a first elastic clamp 201, a second elastic clamp 202, a half of the annular groove 203 and a block 204, the first elastic The clamp 201 and the second elastic clamp 202 are fastened to the sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com