Water-based ink printing process for plastic bag

A water-based ink and plastic bag technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of polluted workshop air, inability to achieve zero content, and volatilization of substances, and achieve the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

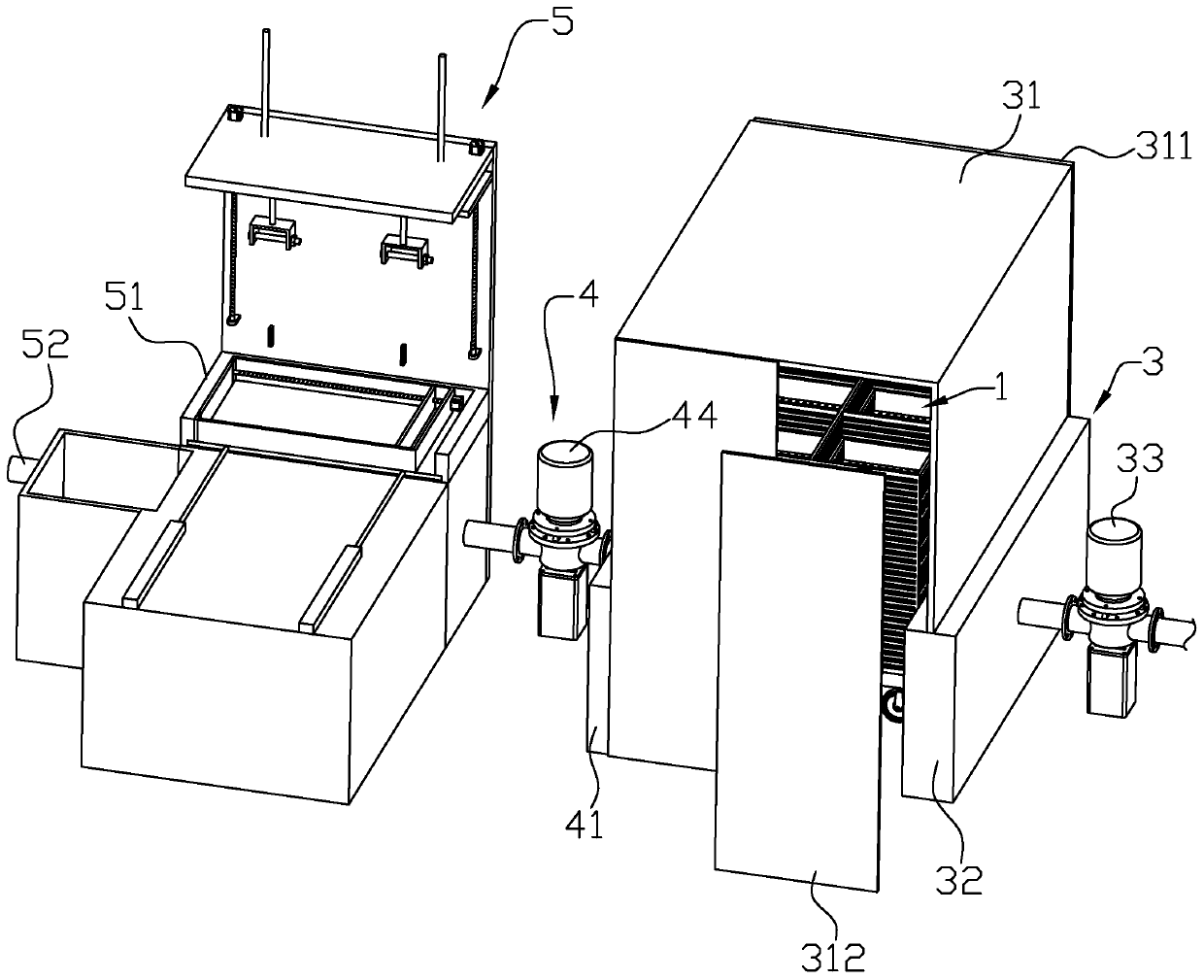

[0041] Such as figure 1 As shown, it is a water-based ink printing process for a plastic bag disclosed by the present invention, including plate making, ink adjustment, printing plate installation, ink scraper, positioning, printing plate inking, debugging, printing and drying, and the step drying includes The hot air system, the hot air system includes a placing device 1 for placing a plurality of plastic bags, a drying device 3 for drying the plastic bags and a processing device 4 for treating waste gas.

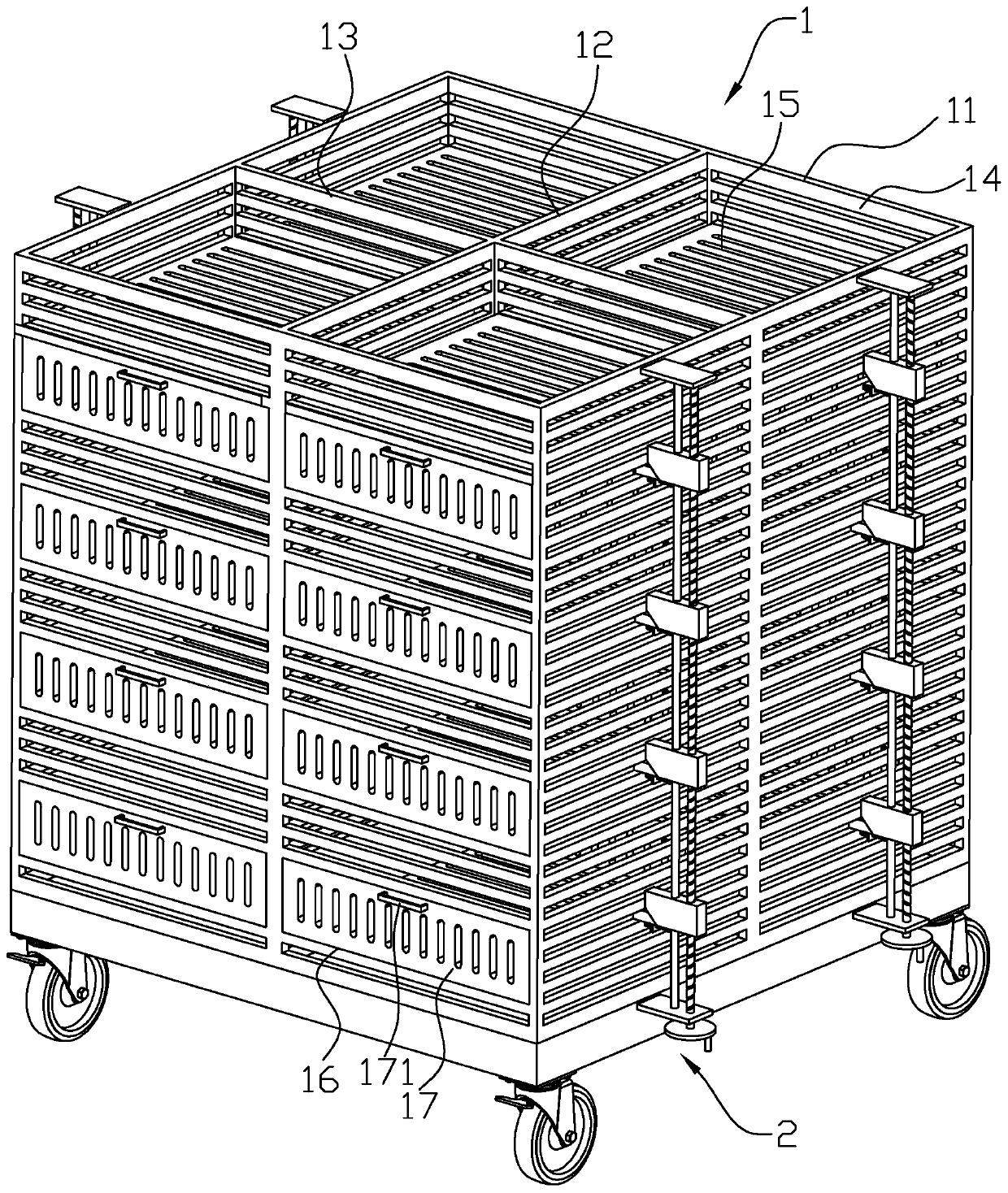

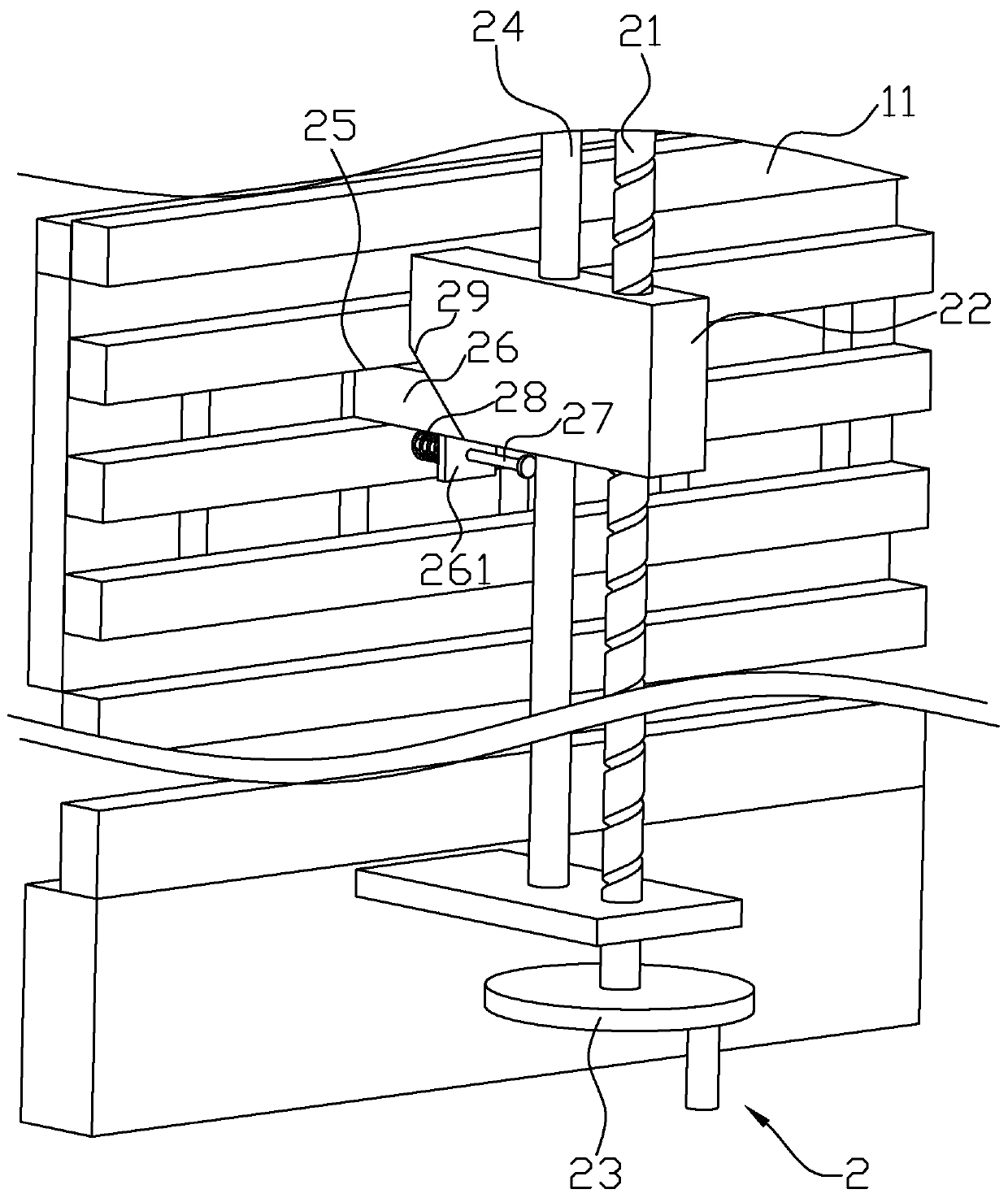

[0042] Such as figure 2 and image 3 As shown, the placement device 1 includes a mobile grid 11, a plurality of rollers installed on the bottom of the mobile grid 11, a split grid 12 fixed in the mobile grid 11, and two wheels respectively fixed on both sides of the split grid 12. A vertical grid frame 13; the partition grid frame 12 and the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com