A circular saw blade automatic spraying equipment

A technology of automatic spraying and circular saw blades, which is applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of large amount of rework, obvious color difference, human injury, etc., achieve uniform surface paint, realize waste gas utilization, prevent The effect of fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

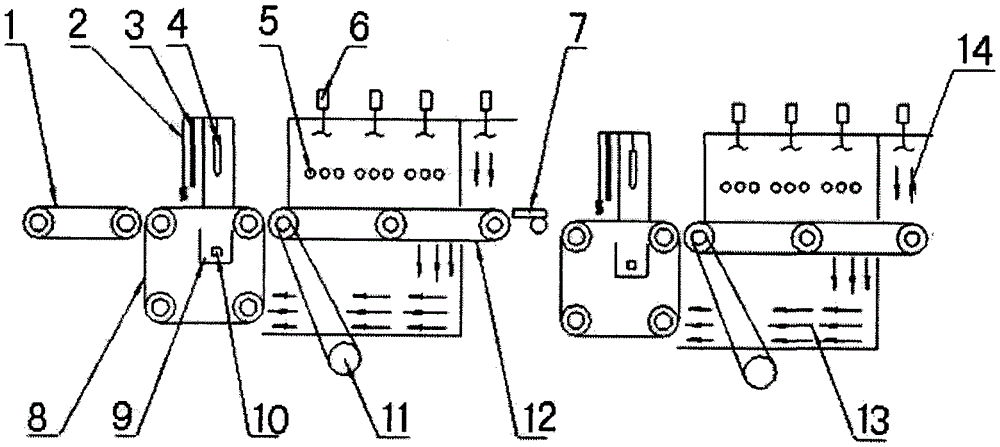

[0010] Depend on figure 1 Known, a kind of circular saw blade automatic spraying equipment, comprises conveyer belt, spraying paint device I, heating and drying device I, automatic sheet turning device, spraying paint device II and heating and drying device II, heating and drying device I, II are all equipped with There is a natural wind cooling port 14, and the conveyer belt 1 sends the circular saw blade to be sprayed onto the steel wire rope 8 of the paint spraying device 1 to remove dust, and after heating and drying the conveying drying net 12 of the drying device 1, it is cooled, and the blade is turned over automatically. The device 7 turns over and the circular saw blade enters the other side for spraying, heating, drying and cooling.

[0011] Paint spraying devices I and II are composed of residual paint box 9, hair brush 2, air blower 3, automatic spray gun 4, steel wire rope 8 and air outlet 10. On the top, the painted product is firstly dusted with a brush 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com