Nano container loaded with corrosion response agent, preparation method and application thereof

A nano-container and curing agent technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems that the coating cannot provide good shielding effect, the impact of the compactness of the coating film, and limit the wide range of applications, etc., to achieve Good application prospects, excellent protection performance, and fast corrosion response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] An aspect of the embodiments of the present invention provides a method for preparing a nanocontainer loaded with a corrosion response agent, which includes:

[0032] Mix mesoporous silica and dispersion solvent uniformly to form a silica dispersion;

[0033] Adding a corrosion response agent to the silica dispersion, mixing evenly, and centrifuging to obtain silica loaded with a corrosion response agent;

[0034] And, uniformly mix the silicon dioxide loaded with the corrosion response agent and the chitosan solution, then add sodium tripolyphosphate into the mixed solution, mix evenly, and centrifuge to prepare the nano container loaded with the corrosion response agent.

[0035] In some more specific embodiments, the weight ratio of the mesoporous silica, dispersion solvent, corrosion response agent solution, chitosan and sodium tripolyphosphate is (2-5):100:(10-15 ):(5-10):(1-5).

[0036] Further, the concentration of the corrosion response agent in the corrosion ...

Embodiment 1

[0078] 1. Preparation of nanocontainers loaded with corrosion responsive agents:

[0079] (1) Mix 2 parts of mesoporous silica (MSN) with 100 parts of absolute ethanol, stir for 2 hours, and ultrasonically disperse for 30 minutes to form a silica dispersion;

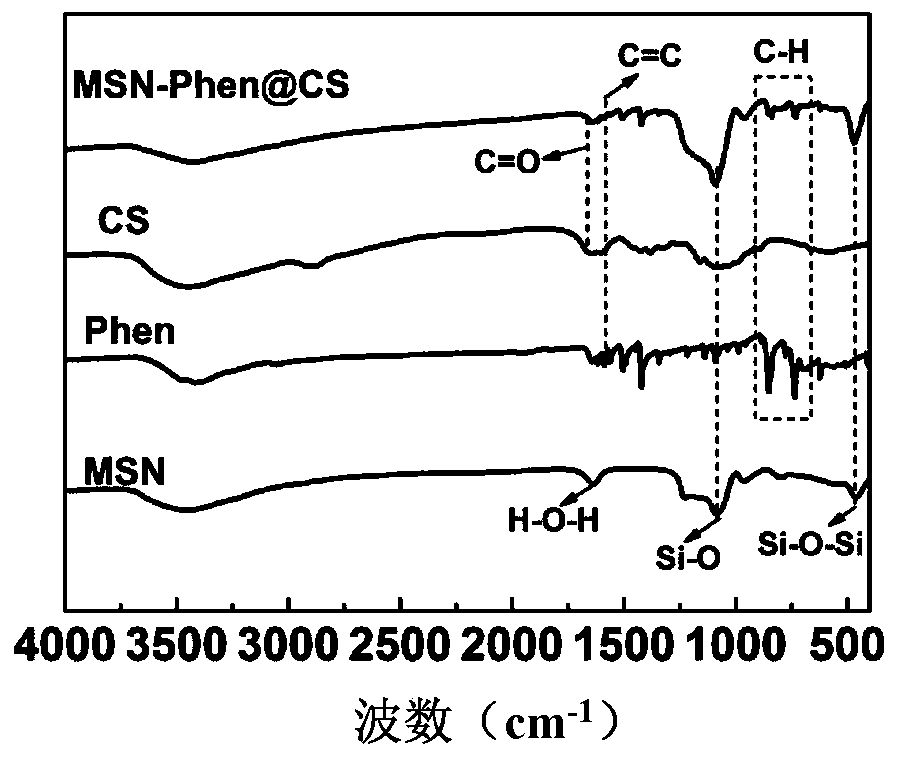

[0080] (2) Add 10 parts of phenanthroline (Phen) solution with a mass fraction of 50 mg / mL to the silica dispersion formed in step (1), then stir for 24 hours, ultrasonically disperse, centrifuge and remove the upper solution, respectively Wash the lower layer of solids with absolute ethanol and deionized water to obtain silica loaded with o-phenanthroline;

[0081] (3) 5 parts of chitosan (CS) solutions with a mass fraction of 2 mg / mL were mixed and stirred for 2 h with the silica loaded with o-phenanthroline prepared in step (2), and then 2 parts of a mass fraction of 2 mg / mL were added. mL of sodium tripolyphosphate (TPP) solution, stirred for 1 h, removed the upper solution after centrifugation, washed the solids in...

Embodiment 2

[0089] 1. The preparation of the nano container loaded with corrosion response agent is the same as in Example 1;

[0090] 2. Preparation of dual-function anti-corrosion coating with self-corrosion early warning and self-repair:

[0091] (1) Mix 1 part of the prepared nano-container loaded with corrosion response agent with 1 part of diluent, stir for 20 minutes, and ultrasonically disperse for 20 minutes to prepare the first mixture;

[0092] (2) Add 40 parts of epoxy resin, 1 part of Triton, and 1 part of BYK-348 to the first mixture, and then stir for 1 hour to form the second mixture;

[0093] (3) Add 10 parts of EK-8538 to the second mixture, stir for 30 minutes, and then disperse by ultrasonic to form a dual-function anticorrosive coating with self-corrosion early warning and self-repair;

[0094] (4) Carbon steel electrodes (2×2cm 2 ) was polished step by step on SiC sandpaper, followed by ultrasonic treatment with absolute ethanol and acetone; the prepared coating wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com