A high-density high-strength silver-carbon composite electrical contact material and its preparation method

An electrical contact material, silver-carbon composite technology, applied in metal material coating process, solid-state diffusion coating, coating and other directions, can solve the problems of low strength, poor density, difficult preparation of silver-carbon composite materials, etc. Excellent contact performance, high material strength, and the effect of increasing welding resistance and arc ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

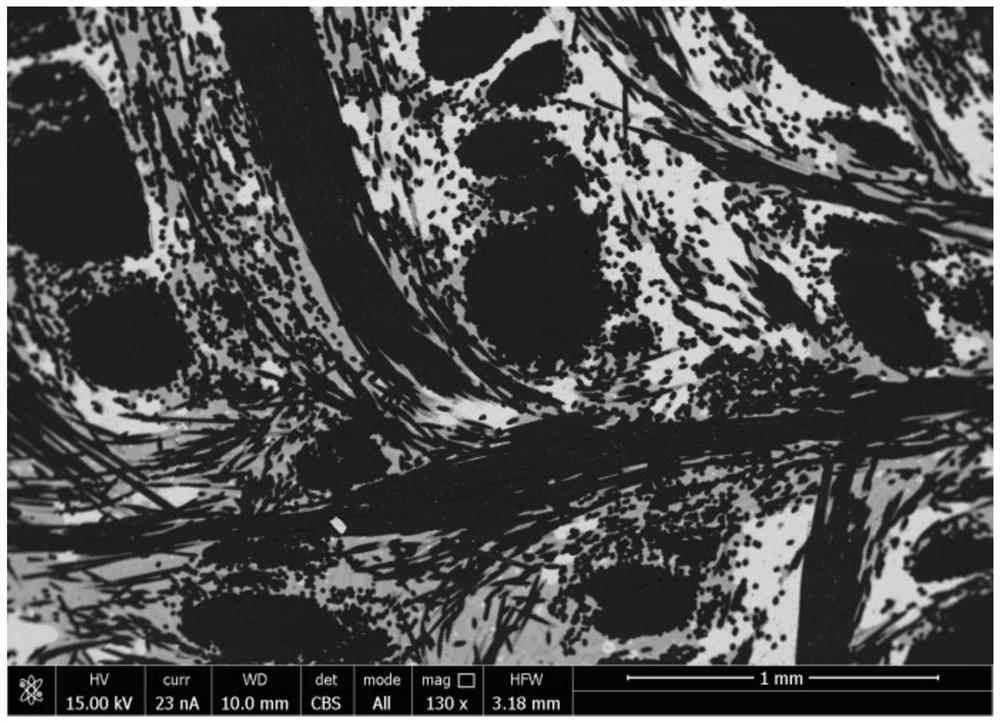

Image

Examples

Embodiment 1

[0022] (1) Weigh 85g of atomized Ag powder (-200 mesh) and 15g of TiZrCuNi (Ti35Zr35Cu15Ni) (-150 mesh), mix them evenly, and then put them into a planetary ball mill for ball milling. The ball milling time is 4h, and the ball-to-material ratio is 5:1 , the speed is 450 rpm.

[0023] (2) Set the density to 1.30g / cm 3 The commercial carbon fiber braided C / C composite material was polished with sandpaper, cleaned with ultrasonic waves, and dried in an oven at a temperature of 100°C for later use.

[0024] (3) Take 5 g of the cut C / C body and embed it in the mixed powder in (1), the mass of the mixed powder is 30 g. Put the sample into a graphite crucible and place it in a vacuum furnace with a vacuum degree of less than 10 -4 pa, heated to 1020°C, held for 1 hour, cooled to room temperature with the furnace, took out the sample, cut off the excess metal, and cut it into Ag-C / C composite electrical contact materials meeting the required size.

[0025] According to the silver-c...

Embodiment 2

[0028] (1) Take 80g of atomized Ag powder (-200 mesh) and 20g of Ti37.5Zr37.5Cu15Ni (-150 mesh), mix them evenly, and then put them into a planetary ball mill for ball milling. The ball milling time is 5h, and the ball-to-material ratio is 5:1 , the speed is 450 rpm.

[0029] (2) Set the density to 1.10g / cm 3 The commercial foam carbon was cut into a certain size, cleaned with ultrasonic waves, and dried in an oven at a temperature of 100°C for later use.

[0030] (3) Take 5 g of the cut foam carbon block and embed it in the mixed powder in (1), the quality of the mixed powder is 35 g. Put the sample into a graphite crucible and place it in a tube furnace with a vacuum of less than 10 -3 pa, heated to 1050°C, held for 1.5h, cooled to room temperature with the furnace, took out the sample to remove excess metal, and cut it into the required contact size to obtain the Ag-C composite electrical contact material.

[0031] According to the silver-carbon composite electrical cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com