Automatic dredging and draining device for autonomous power pipeline

A technology for power pipelines and drainage devices, applied in vertical pipelines, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as horizontal flue corrosion, condensate water cannot be drained, and water bodies cannot be unified in one place. , to achieve the effect of reducing labor and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

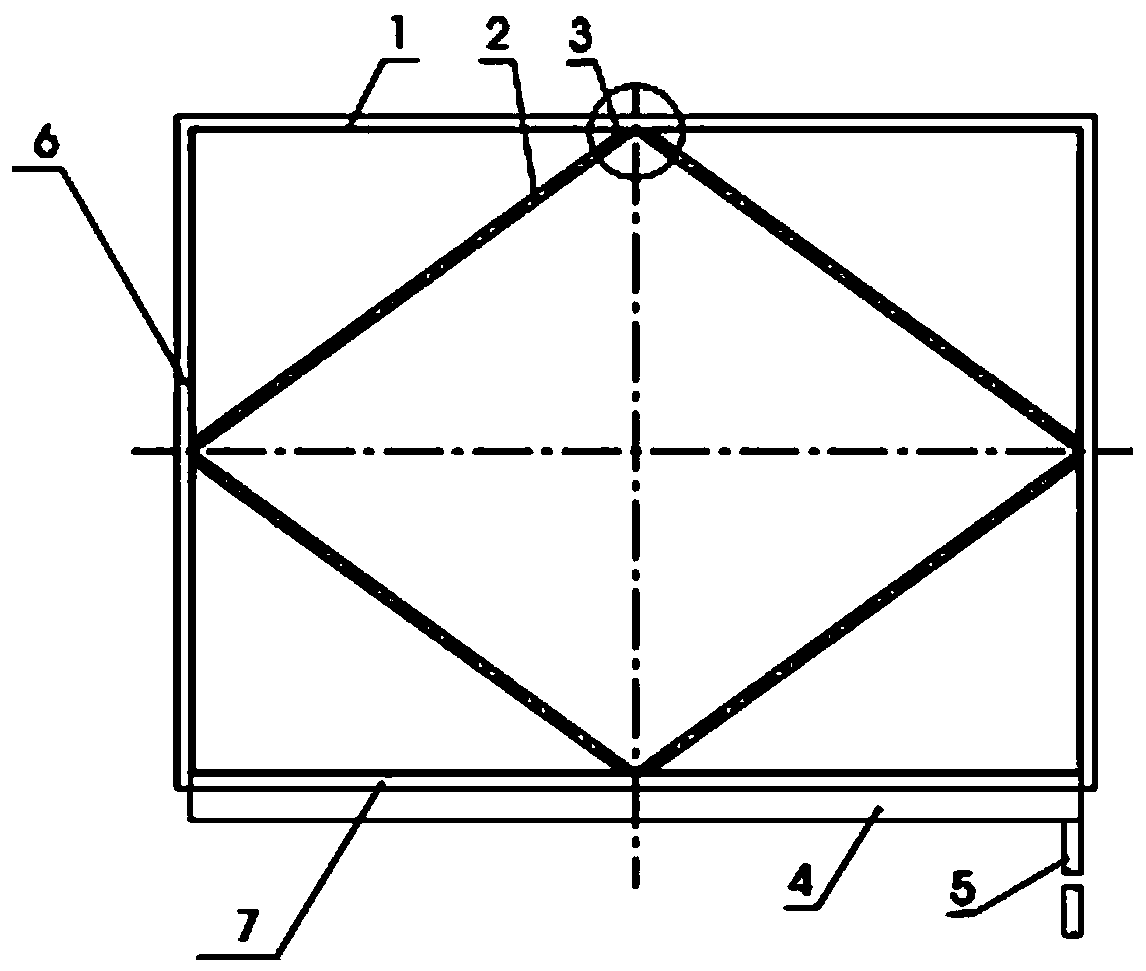

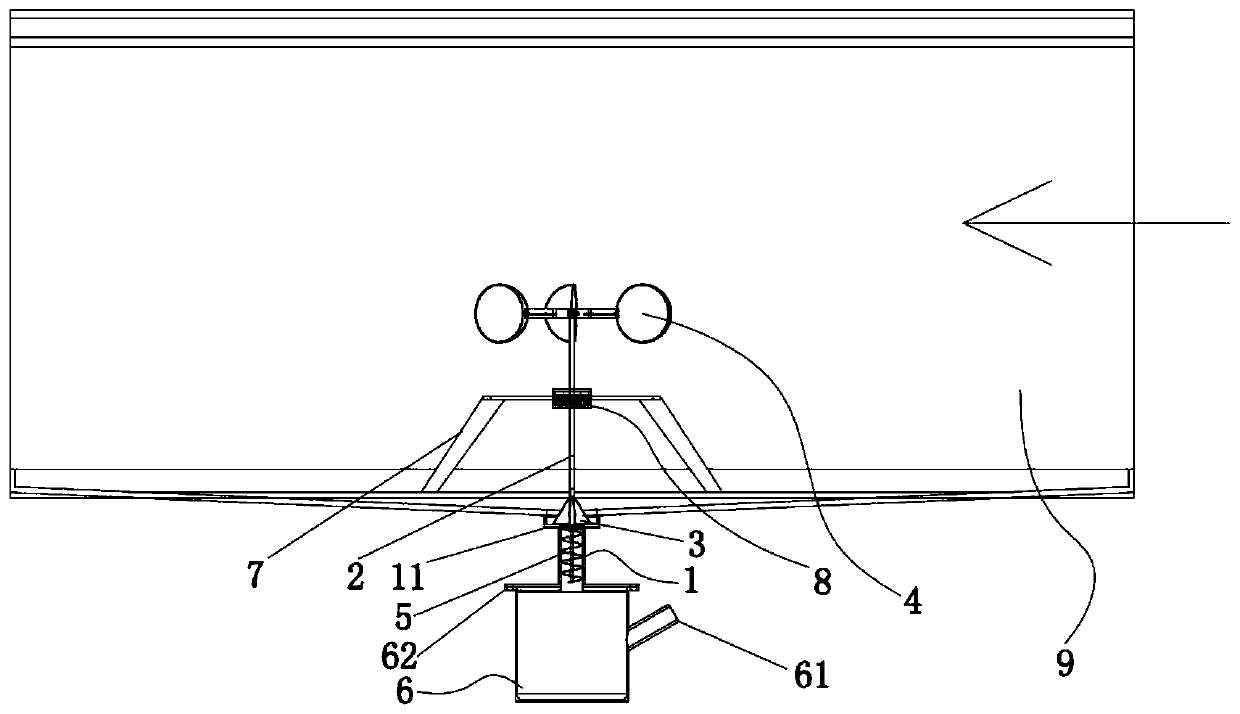

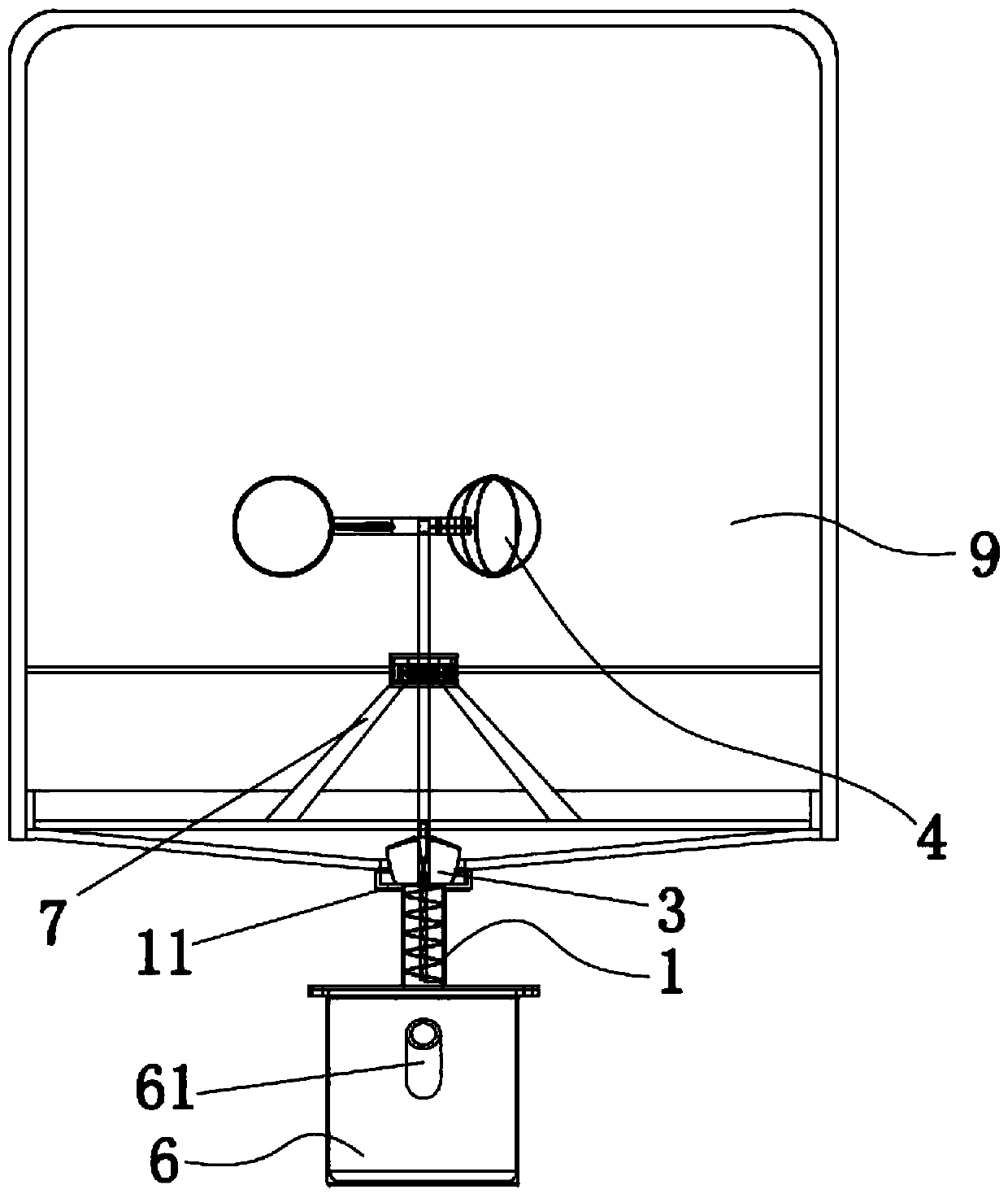

[0039] Such as Figures 2 to 4 As shown in one of them, the autonomous power pipeline automatic dredging and drainage device of the present invention is used for dredging and draining the flue gas transmission pipeline 9, which includes:

[0040] Sewage pipe 1, the upper end of which is fixedly connected to the lower end surface of the flue gas transmission pipeline 9 and communicates with the interior of the flue gas transmission pipeline 9, and is used to discharge accumulated water and dirt in the flue gas transmission pipeline 9. The sewage pipe 1 is connected with the flue gas The end connected to the transmission pipeline 9 is a flared structure 11. In order to facilitate flow diversion, the bottom of the flue gas transmission pipeline 9 is a funnel-shaped structure and the flared structure 11 of the sewage pipe 1 is connected with the funnel-shaped structure. bottom connection;

[0041] The rotating shaft 2 is arranged coaxially with the sewage pipe 1 and one end penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com