A nutation transmission device for cambered secondary enveloping crown gears

A secondary envelope and transmission technology, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of single installation method, inflexible use, vibration and impact of meshing on the same side, and simplify the support structure of the device , Improving the stability of motion and the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

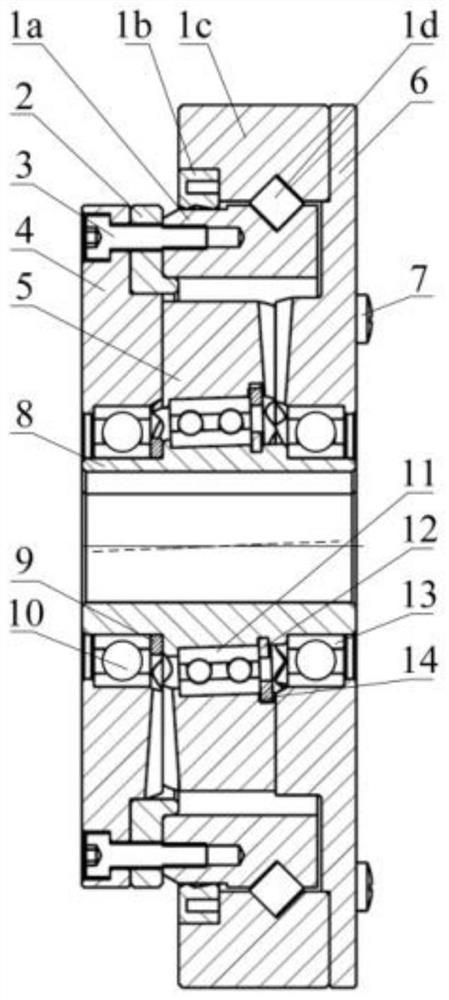

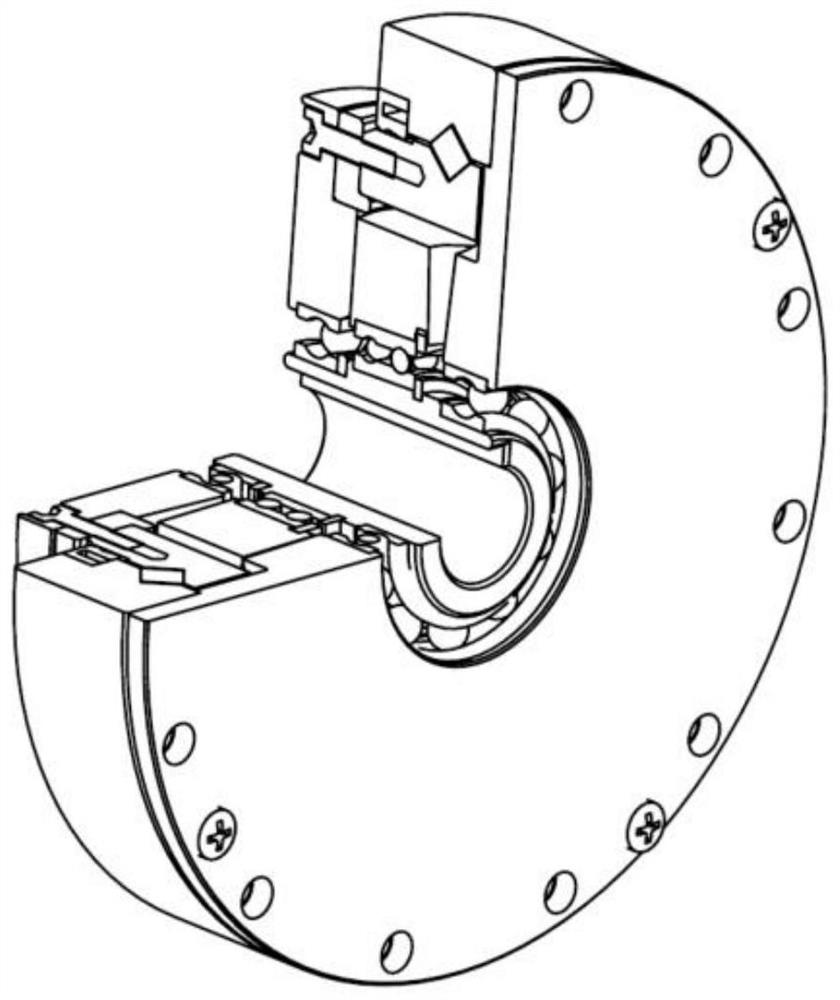

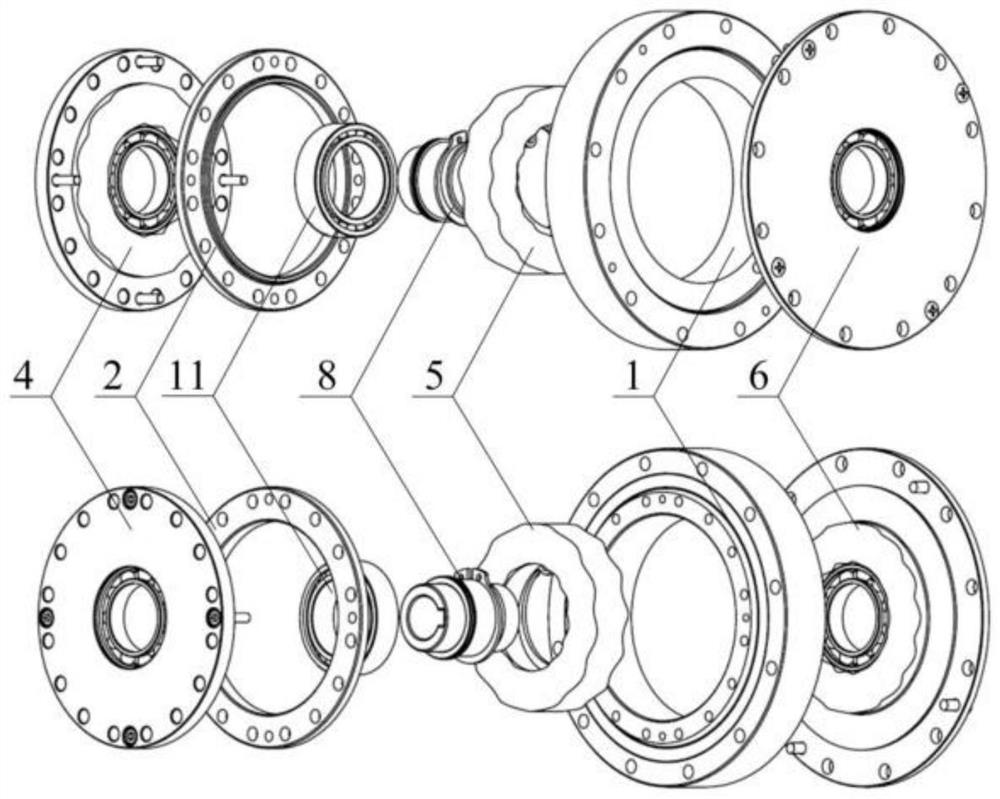

[0048] refer to Figure 1-3 As shown, it is an embodiment of the crown gear nutation transmission device of the present invention, comprising a crossed roller bearing 1 composed of an inner ring 1a, an oil seal 1b, an outer ring 1c, and a cylindrical roller 1d, wherein the inner ring of the crossed roller bearing 1 is The ring 1a and the left crown gear 4 are fixedly connected by screws 3, and there is a washer 2 therebetween. The outer ring 1c of the crossed roller bearing 1 and the right crown gear 6 are fixedly connected by screws 7. The invention adopts the crossed roller bearing to simplify the support of the device The structure can withstand large external axial force and radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com