Computer hardware durability test system

A computer hardware and test system technology, applied in the direction of detecting faulty computer hardware, computing, error detection/correction, etc., can solve the problems of not being able to get results quickly and intuitively, and there is no good solution for durability, and achieve results Intuitive, time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

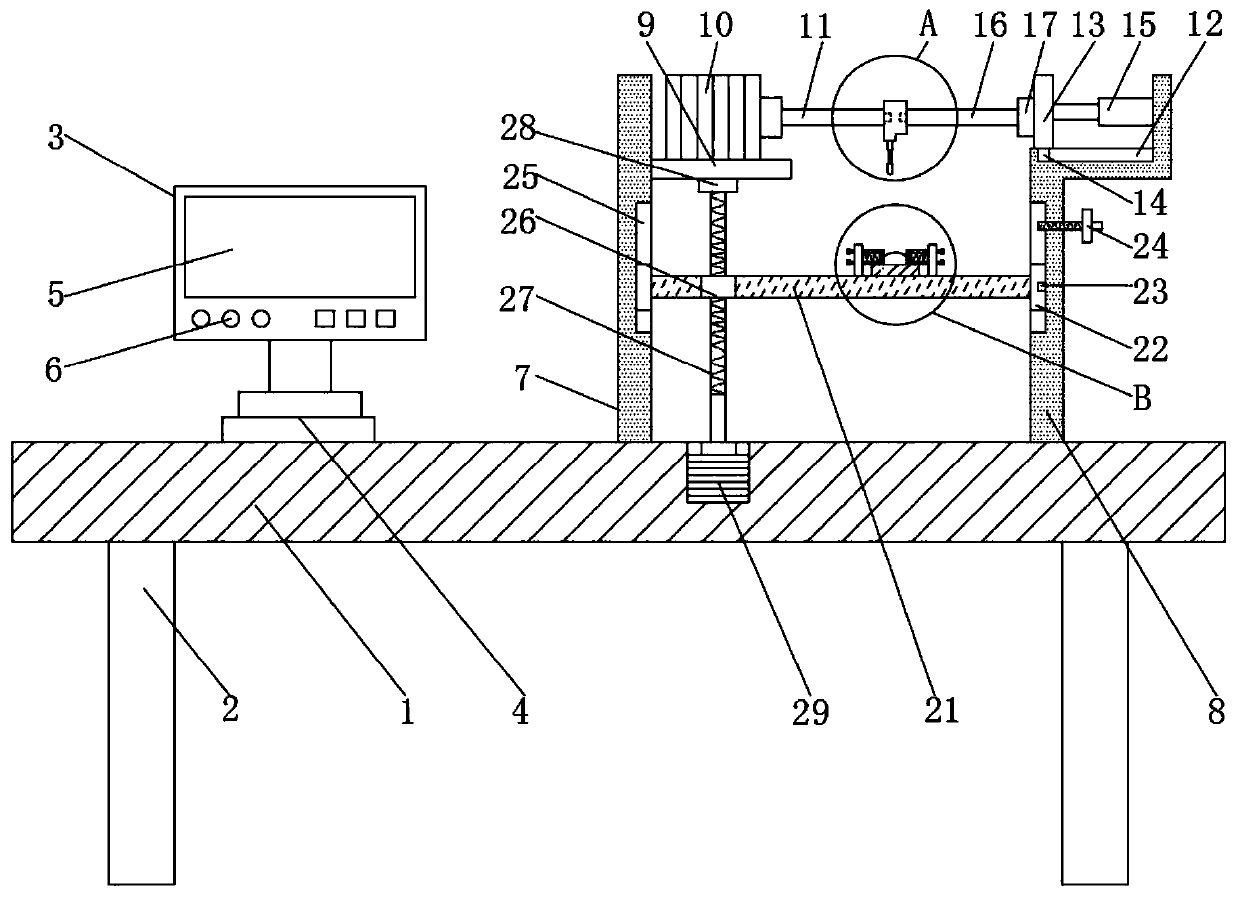

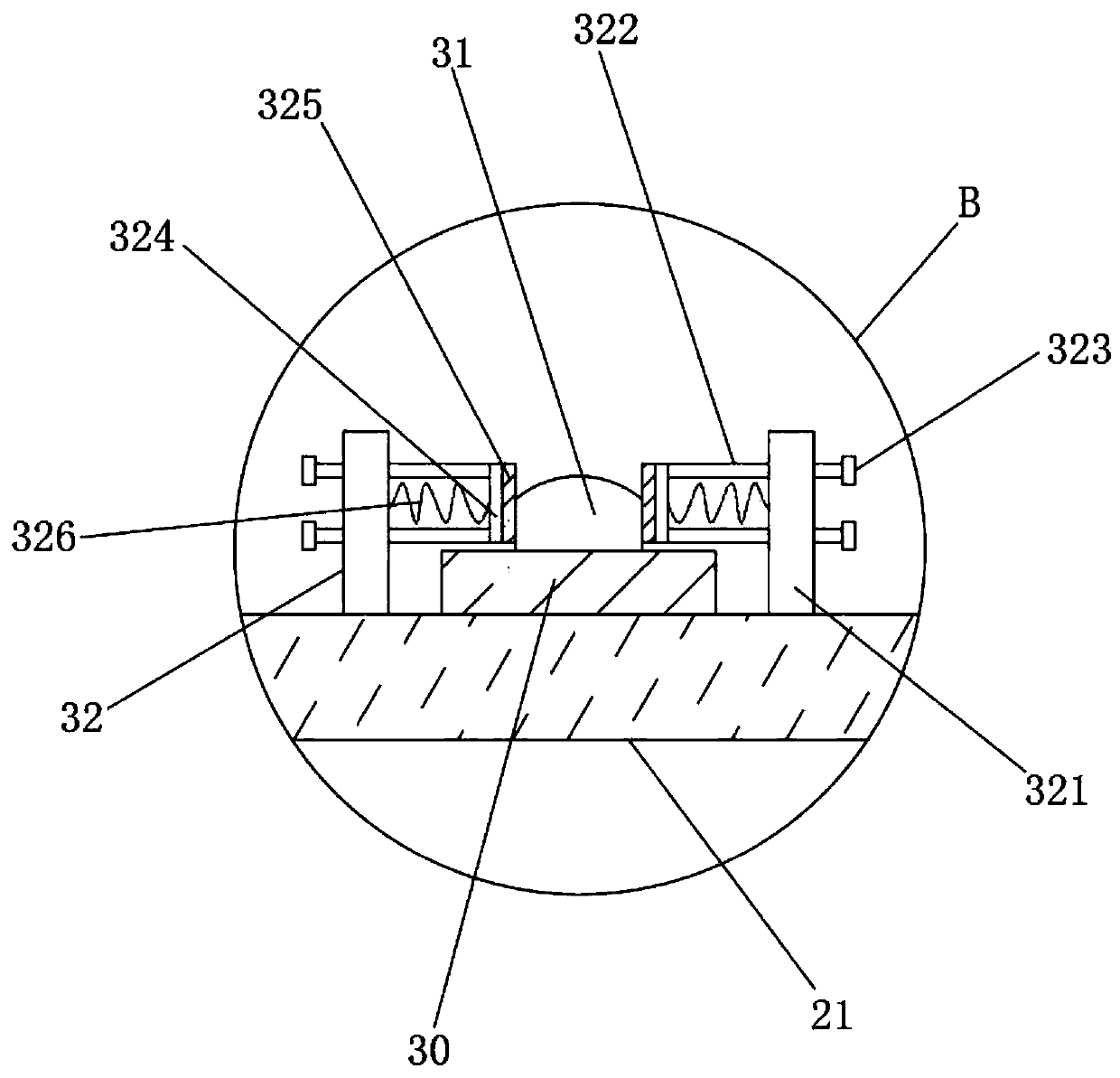

[0031] See Figure 1~6 In the embodiment of the present invention, a computer hardware durability performance test system includes a workbench 1. A number of support legs 2 are provided symmetrically at the lower end of the workbench 1, and a computer testing device 3 is provided on the left side of the upper end of the workbench 1. The test equipment 3 includes a rotating base 4, the upper end of the rotating base 4 is equipped with an equipment body 5, the lower front end of the equipment body 5 is provided with a number of control keys 6, and the equipment body 5 is installed with counting software and pressure monitoring software;

[0032] A left side plate 7 and a right side plate 8 are respectively provided on the right side of the upper end of the workbench 1, the left side plate 7 is located on the left side of the right side plate 8, and the upper right side of the left side plate 7 is provided with a mounting plate 9, and the mounting plate A motor 10 is installed on 9,...

Embodiment 2

[0038] Such as Image 6 As shown, the difference between the second embodiment and the first embodiment is that: the first rotating shaft 11 and the second rotating shaft 16 are engaged with the second pressing structure 20. The second pressing structure 20 is composed of the second mounting block 201 and the second pressing member 202. The structure of the second block 201 and the second pressing part 202 is the same as the installation block one 191 and the first pressing part 192, and the second pressing part 202 is arranged on the right side of the lower end of the second installation block 201, and the bottom of the second pressing part 202 contacts the mouse body 31 Right click.

[0039] The working principle of the present invention is:

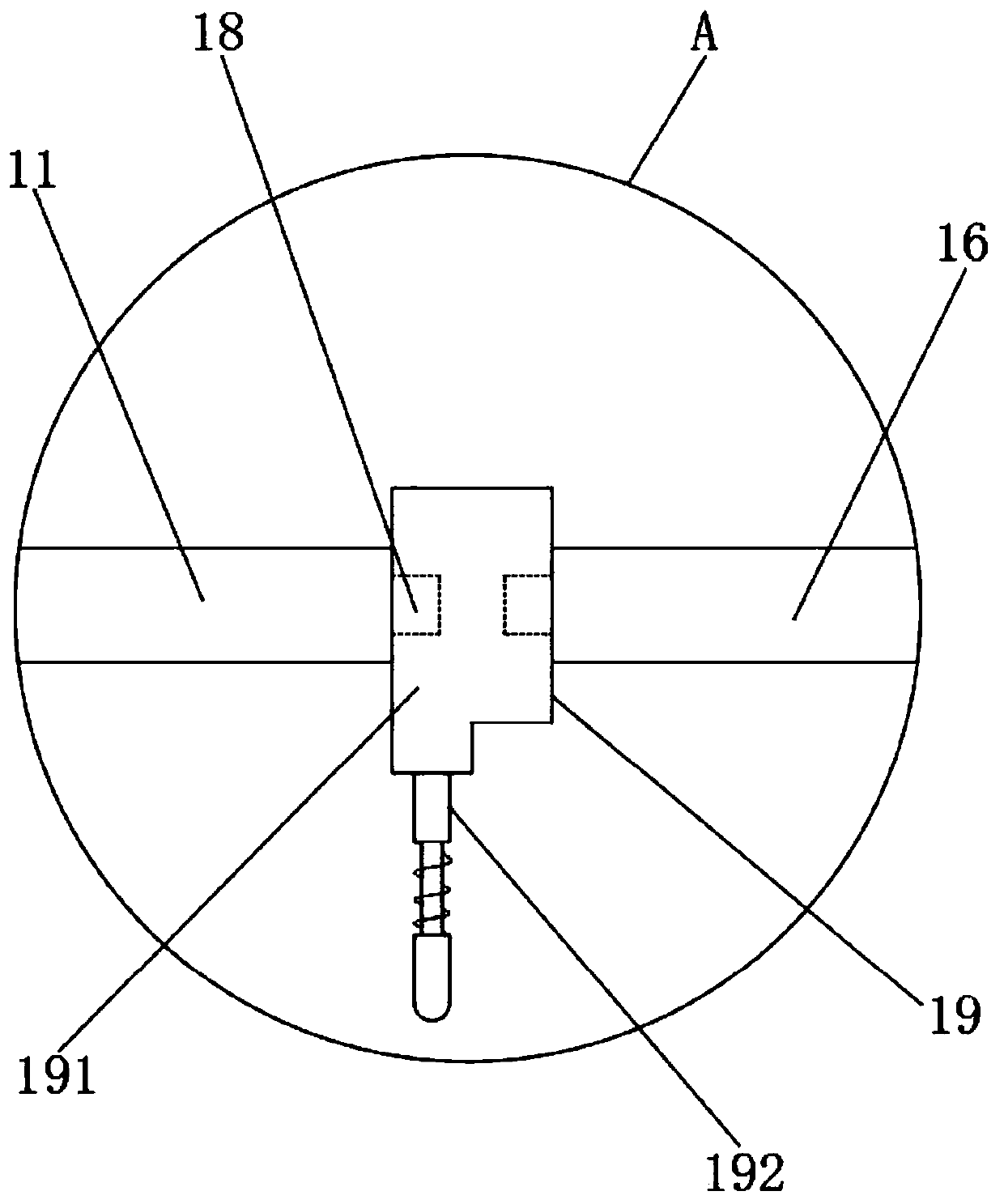

[0040] When the present invention is in use, first select the pressing structure 19 or pressing the structure 2 20 according to the actual test requirements (testing the left or right button of the mouse body 31). Take the pressing structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com