An automatic rotating and leveling device for insoles

An automatic rotation and leveling technology, which is applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve problems such as low work efficiency, uneven flattening, and safety risks, so as to achieve convenient use of equipment, speed up work efficiency, and improve The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

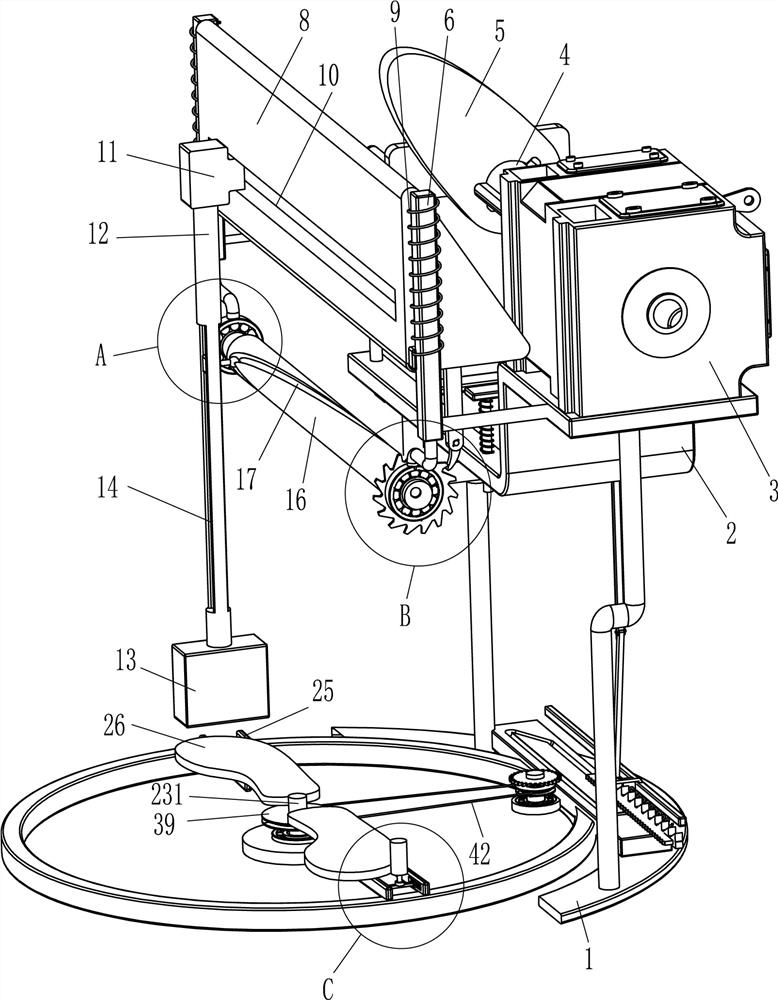

[0028] An automatic rotary leveling device for insoles, such as figure 1 , 2 , 4 and 5, including a base 1, a support 2, a power assembly, a lifting assembly, a lateral movement assembly and a placement assembly, the front side of the base 1 is provided with a support 2, and the support 2 is provided with a power assembly powered by a motor. The base 1 is provided with a lifting component that moves up and down by sliding, and a lateral movement component that moves through sliding is connected between the lifting component and the power component, and the base 1 is provided with a placement component.

[0029] Such as figure 1 and 5 As shown, the power assembly includes a geared motor 3, a first rotating shaft 4 and a cam 5, the upper left side of the bracket 2 is fixed with a geared motor 3 by bolts, and the output shaft of the geared motor 3 is connected with a The first rotating shaft 4 is provided with two cams 5 .

[0030] Such as figure 2 As shown, the lifting ass...

Embodiment 2

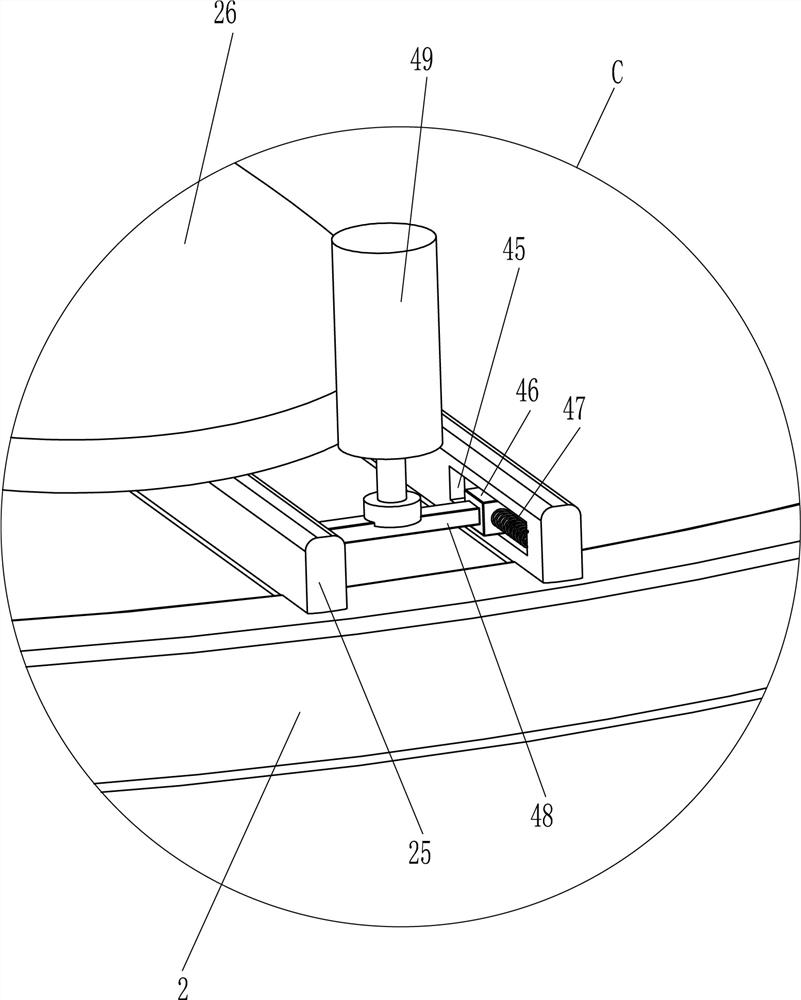

[0039] On the basis of Example 1, such as figure 2 As shown, in order for the equipment to work more stably, it also includes a support rod 25 and a backing plate 26. Two groups of support rods 25 are symmetrically arranged on the top of the base 1, and a backing plate 26 is provided on the top of each group of support rods 25.

[0040] Such as figure 1 As shown, in order to use the device better, it also includes a hollow rod 27 and a placement frame 271. The base 1 is symmetrically provided with a hollow rod 27 front and back, and a placement frame 271 is placed in the hollow rod 27. The placement frame 271 and the placement groove 24 fits.

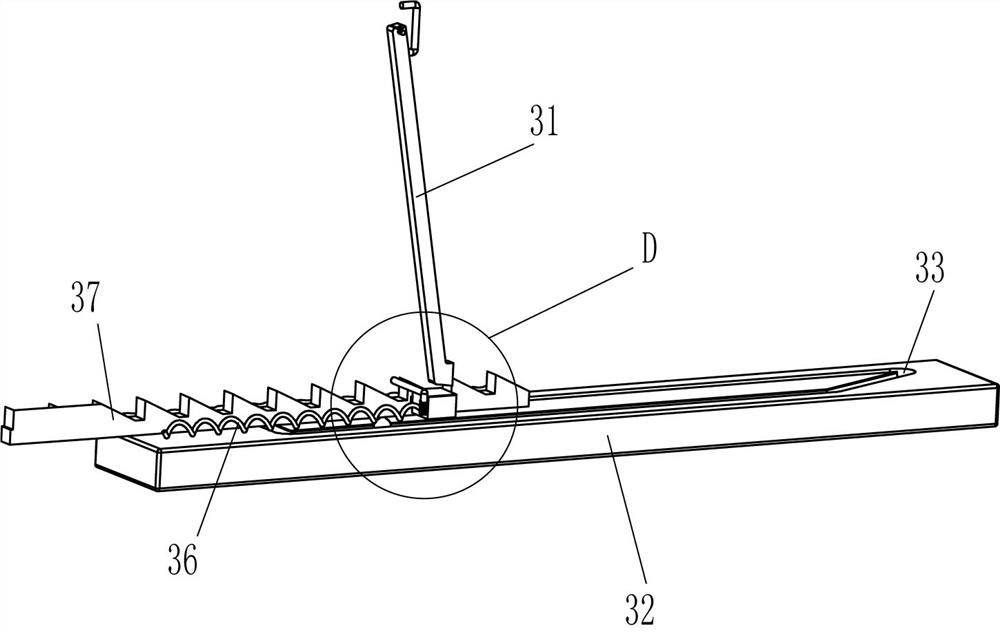

[0041] Such as image 3 , 4 , 5, 8 and 9, in order to improve the automation of the equipment, it also includes a concave lifting rod 28, a second elastic member 29, a second connecting rod 30, a swing rod 31, a slide plate 32, a straight slide rail 34, the first Four slide blocks 35, the third elastic member 351, the fourth elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com