Mask disinfection treatment equipment

A technology for processing equipment and masks, which is applied in the field of disinfection and processing equipment for masks to achieve enhanced reuse performance and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

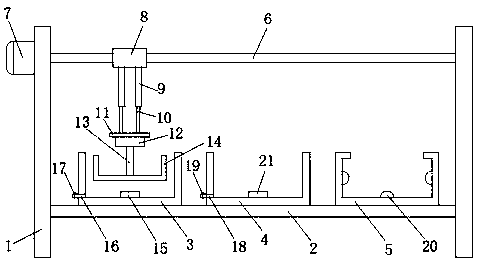

Image

Examples

Embodiment 1

[0030] The first cleaning chamber 3 is filled with a first cleaning solution, and the first cleaning solution is composed of the following substances in corresponding parts by weight: 4 parts of nano-titanium dioxide, 3 parts of nonylphenol polyoxyethylene ether, 1 part of Sodium hexametaphosphate, 2 parts meteorite powder, 150 parts deionized water.

[0031] The second cleaning solution is contained in the second cleaning chamber 4, and the second cleaning solution is composed of the following substances in corresponding parts by weight: 4 parts of tea tree essential oil, 5 parts of sodium dodecylbenzenesulfonate, 200 parts of parts deionized water.

Embodiment 2

[0033] The first cleaning chamber 3 is filled with a first cleaning solution, and the first cleaning solution is composed of the following substances in corresponding parts by weight: 6 parts of nano-titanium dioxide, 5 parts of nonylphenol polyoxyethylene ether, 2 parts of Sodium hexametaphosphate, 4 parts meteorite powder, 155 parts deionized water.

[0034] A second cleaning solution is contained in the second cleaning chamber 4, and the second cleaning solution is composed of the following substances in corresponding parts by weight: 6 parts of tea tree essential oil, 8 parts of sodium dodecylbenzenesulfonate, 210 parts deionized water.

Embodiment 3

[0036] The first cleaning liquid is contained in the first cleaning chamber 3, and the first cleaning liquid is composed of the following substances in corresponding parts by weight: 7 parts of nano-titanium dioxide, 6 parts of nonylphenol polyoxyethylene ether, 3 parts of Sodium hexametaphosphate, 5 parts of meteorite powder, 160 parts of deionized water.

[0037] The second cleaning liquid is contained in the second cleaning chamber 4, and the second cleaning liquid is composed of the following substances in corresponding parts by weight: 8 parts of tea tree essential oil, 10 parts of sodium dodecylbenzenesulfonate, 220 parts deionized water.

[0038] The nano-titanium dioxide and meteorite powder in the first cleaning solution provided in the equipment of the present invention can vibrate under the action of the first ultrasonic transmitter 15, fully exerting its antibacterial and antibacterial effect, and ensuring the sterilization effect of the mask. The tea tree essenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com