Superconducting magnetic separation method for realizing continuous ore feeding and separation by using swivel structure

A technology of superconducting magnets and superconducting magnets, applied in the field of superconducting magnetic separation, can solve the problems of continuous ore feeding and continuous separation by using the strong magnetic field of solenoid superconducting magnets, and achieves increased equipment throughput and huge economic effects. , The effect of reducing valve wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

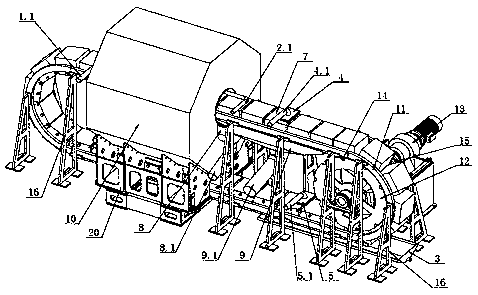

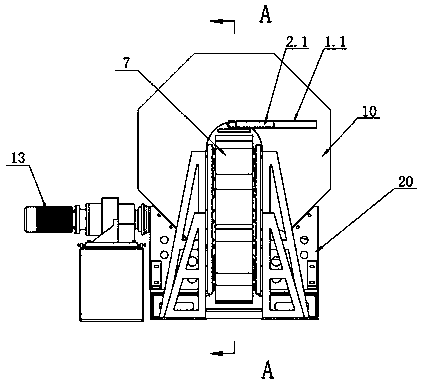

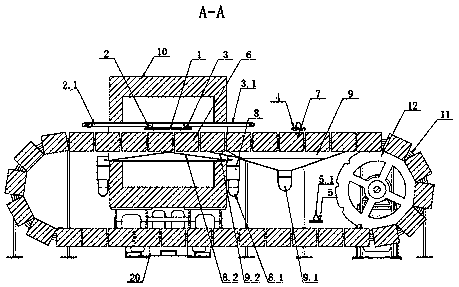

[0037] Such as Figure 1-3 As shown, the method is to realize continuous feeding and sorting by controlling a swivel medium box containing several sorting chambers to perform cyclical rotary motion in a horizontal superconducting magnet magnetic field. On the upper part of the magnetic field of the magnetizer and above the swivel medium box, there are an ore feeding port 1 and a left in-field flushing port 2 and a right in-field flushing port 3 located on both sides of the ore feeding port 1. The magnetic field of the superconducting magnet The lower part of the inside, below the swivel medium box, is provided with a non-magnetic ore collection channel 8.2 and a magnetic ore collection channel 9.2. Outside the superconducting magnet, above the swivel medium box, an off-site flushing discharge port is arranged in turn. 4 and the off-site secondary flushing discharge port 5, the swivel medium box realizes the cyclic rotary motion in the superconducting magnet magnetic field by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius of gyration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com