Bearing assembly device capable of automatically assembling rolling ball

A bearing assembly and automatic assembly technology, applied in the field of bearing processing, can solve the problems of low efficiency, slow efficiency, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

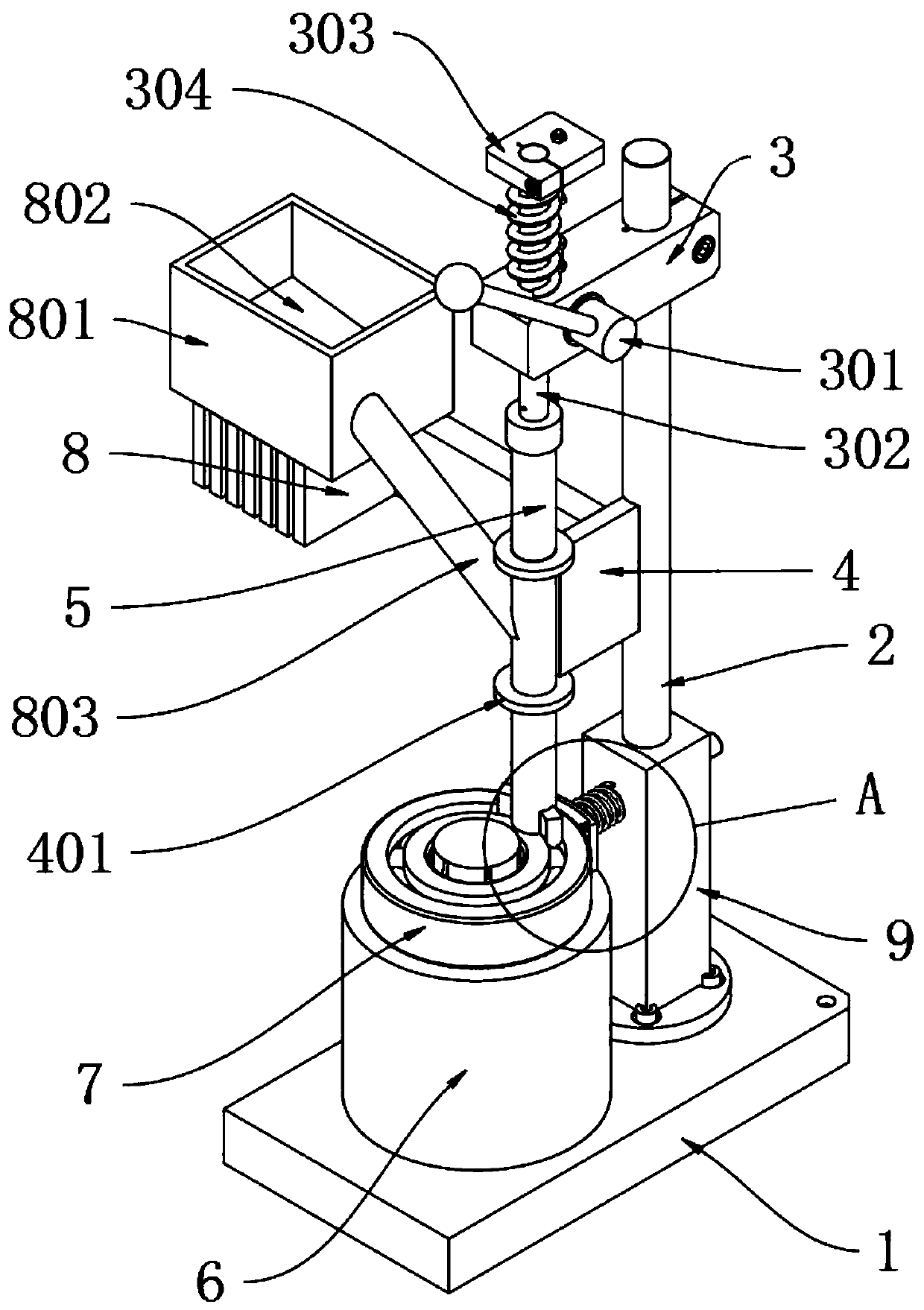

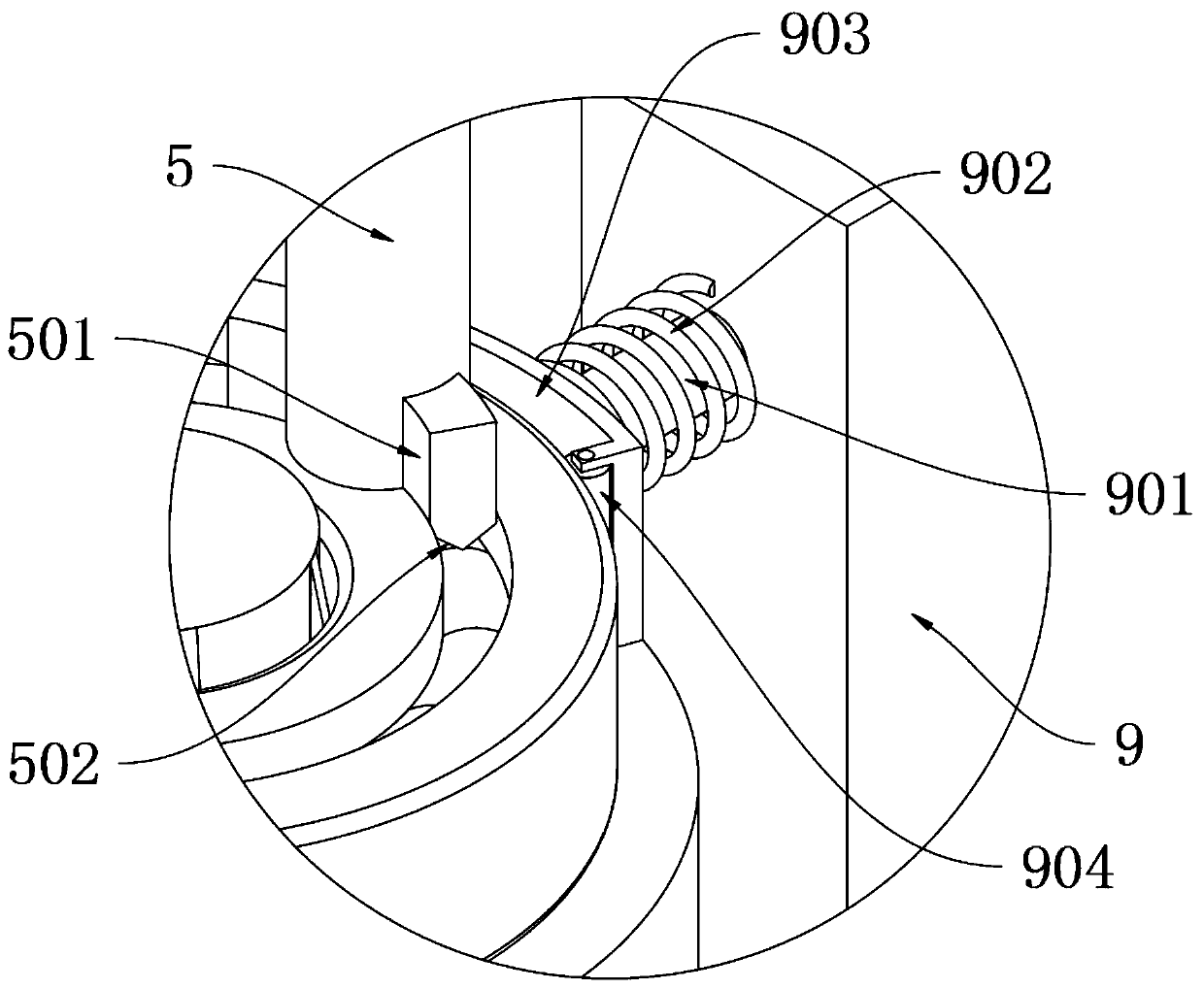

[0036] as attached figure 1 To attach Figure 10 Shown:

[0037] The present invention provides a bearing assembly device capable of automatically assembling balls, comprising a base 1; a support frame 2 is fixedly installed vertically upward on the rear end of the top plane of the base 1; a lifting mechanism 3 is fixedly installed on the upper end of the support frame 2, and the lifting mechanism 3 includes a wheel shaft 301, a pressure rod 302, a stopper 303, a spring A304, teeth 305, a handle 306 and a gear 307. The front end of the lifting mechanism 3 is vertically inserted with a pressure rod 302, and the upper end of the pressure rod 302 is fixedly equipped with a stopper 303 , the lower end of the pressing bar 302 is fixedly connected with the upper end of the bead-feeding mechanism 5, and the upper end of the pressing bar 302 below the block 303 is sleeved with a spring A304, and the lower end of the spring A304 is against the top plane of the elevating mechanism 3, a...

Embodiment 2

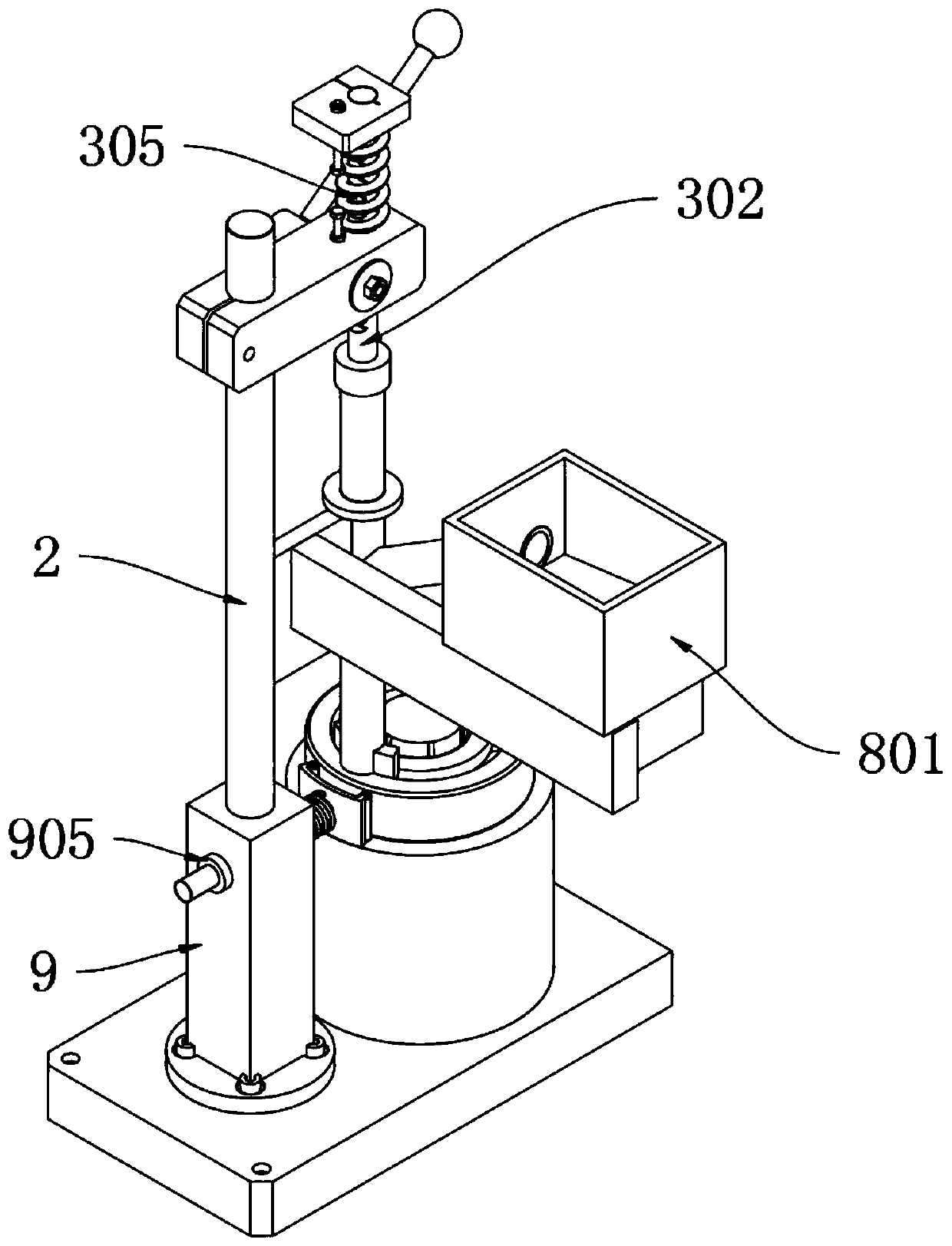

[0041] On the basis of embodiment 1, as attached figure 1 To attach image 3 Shown:

[0042] The present invention provides a bearing assembly device capable of automatically assembling balls. The material storage mechanism 8 includes a material storage box 801, a dumping bottom plate 802 and a connecting pipe 803. A rectangular material storage box 801 is fixedly installed on the top of the left end of the material storage mechanism 8. The bottom of the inner cavity of the material storage box 801 is fixedly provided with a dumping bottom plate 802 with a high left end and a low right end. The notch structure adapted on the outer wall of the ball feeding mechanism 5, the inner diameter of its connecting pipe 803 is consistent with the inner diameter of the ball feeding mechanism 5, and the balls can be contained in the material storage box 801, which can be used as the docking port of the ball feeding mechanism 5. When 503 is in contact with the lower end of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com