Variable print control bars

A printing head and inkjet printing machine technology, applied in printing, printing devices, electrical components, etc., can solve problems that affect the analysis and processing of nozzle test patterns, distortion, and irregularity of substrate conveying in printing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

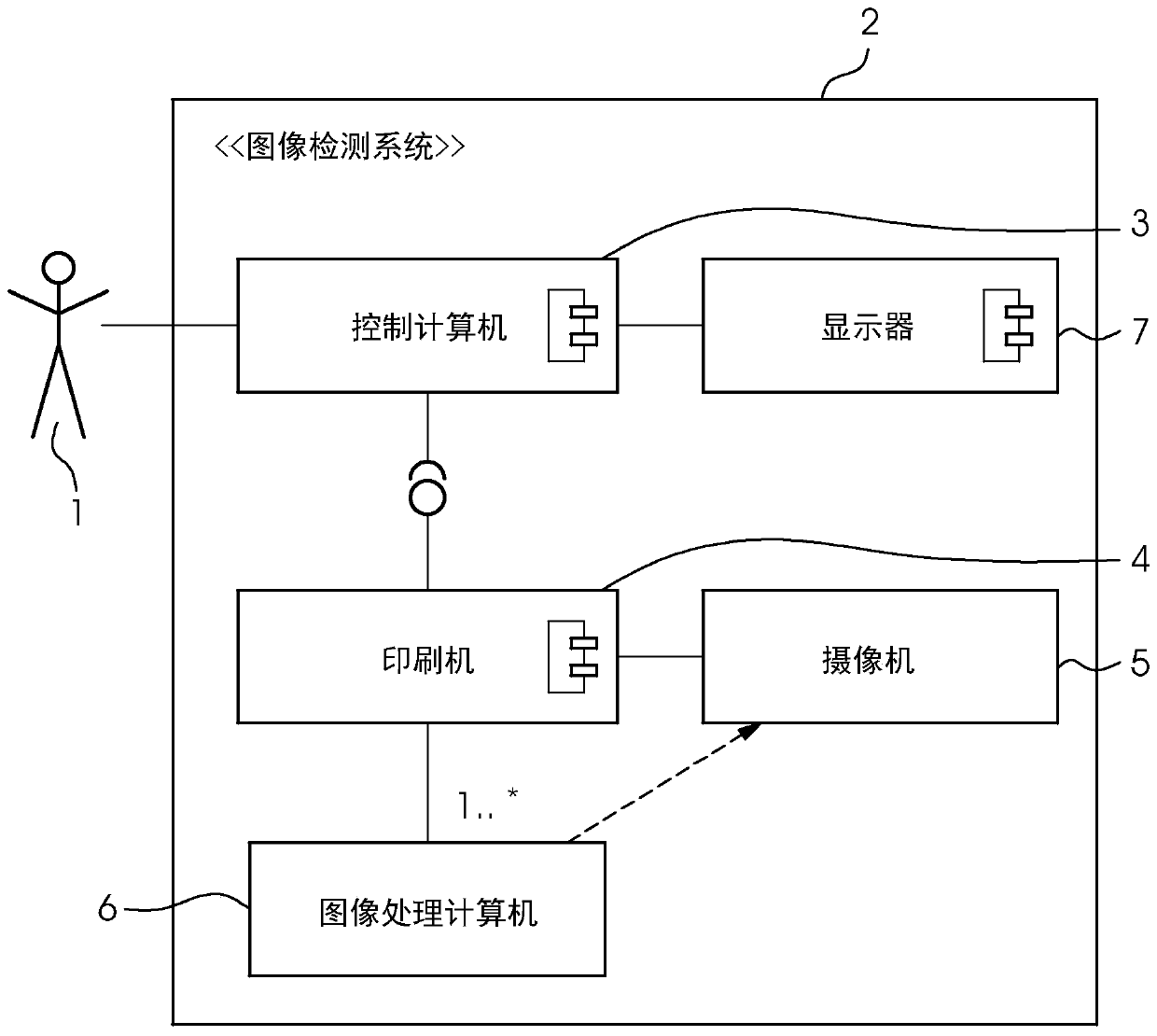

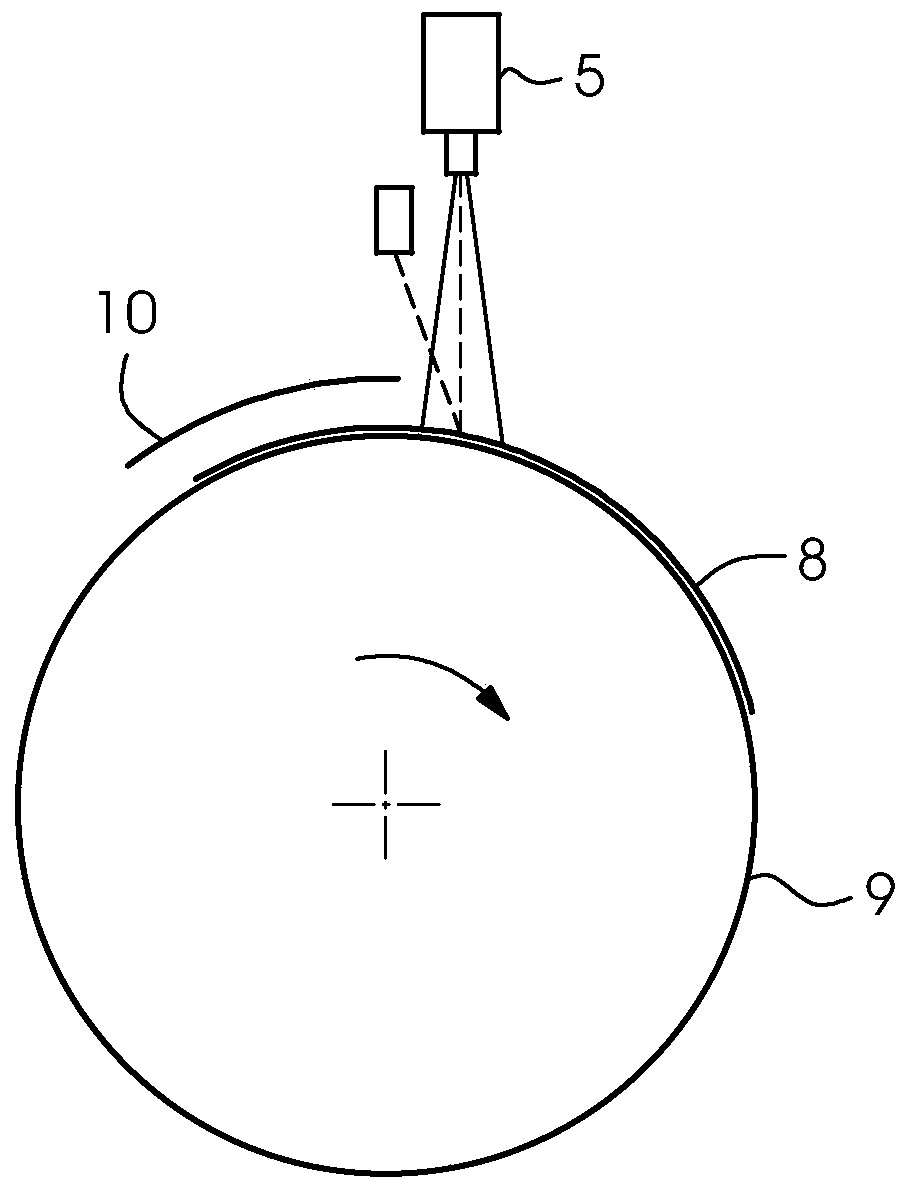

[0023] figure 1 An example of an image detection system 2 adopting the method according to the present invention is shown. The image detection system 2 includes at least one image sensor 5 which is usually a camera 5 integrated into the sheet printing press 4. In this way, at least one camera 5 captures the printed images produced by the printing press 4 and sends the data to the computers 3, 6 for analysis and processing. The computers 3, 6 can be their own separate computers 6 (for example, one or more specialized image processing computers 6) or can be the same as the control computer 3 of the printing press 4. At least the control computer 3 of the printing press 4 has a display 7 on which the results of the image monitoring are displayed to the user 1.

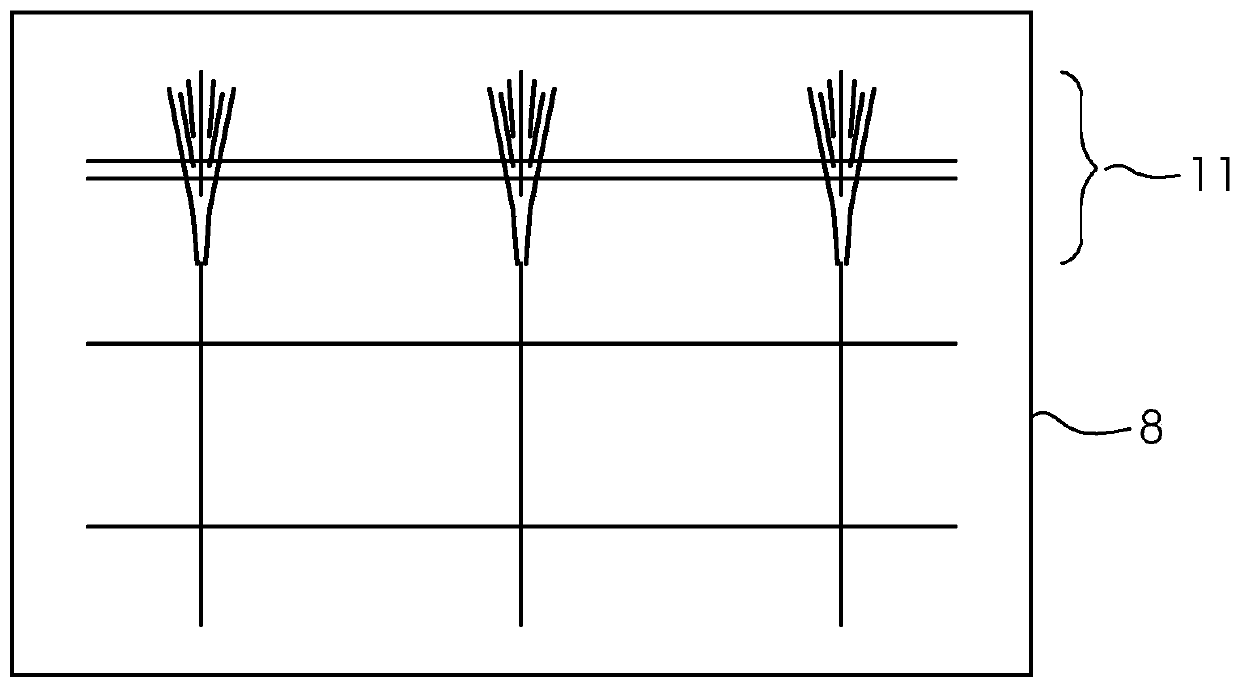

[0024] When transporting the printing sheet 8 in the inkjet printer, the above-mentioned reduction of the printing sheet will occur here, and this reduction of the printing sheet has a negative effect on the image capture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com